Silicate plasticizing powder

A technology of plasticizing powder and silicate, applied in the field of silicate plasticizing powder, can solve the problems of low product qualification rate, brittle block steel, easy cracking and other problems, and achieve high product qualification rate and compressive strength. The effect of high and slow compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: Silicate plasticizing powder comprises:

[0017] (1) Carrier: 1000kg;

[0018] (2) The first group of anionic surfactants: one or two of AES, AL70, EAC70, 11.0% to 0.25% (mass fraction relative to the carrier);

[0019] (3) The second group of anionic surfactants: sulfonic acid or sulfate ester, 11.0% to 0.25% (mass fraction relative to the carrier);

[0020] (4) Accelerator, 5% to 0 (mass fraction relative to the carrier).

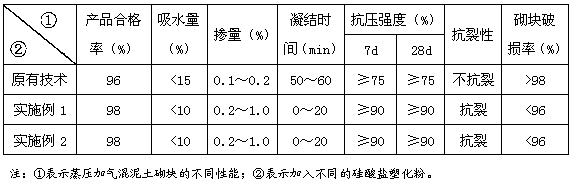

[0021] The results are shown in Table 1.

Embodiment 2

[0022] Embodiment 2: Silicate plasticizing powder comprises:

[0023] (1) Carrier: 1000kg;

[0024] (2) The first group of anionic surfactants: one or two of AES, AL70, EAC70, 14.0% ~ 1.0% (mass fraction relative to the carrier);

[0025] (3) The second group of anionic surfactants: fatty alcohols, 8.0% to 0.5% (mass fraction relative to the carrier);

[0026] (4) Accelerator: 5% to 0 (mass fraction relative to the carrier).

[0027] The results are shown in Table 1.

[0028] Table 1 Comparison of properties of autoclaved aerated concrete blocks under different conditions

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com