Preparation method of boron nitride-coated carbon nanotubes

A boron nitride package and carbon nanotube technology, applied in chemical instruments and methods, nitrogen compounds, nanotechnology, etc., can solve problems such as poor interface bonding, and achieve the effects of low cost, simple use of equipment and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The present invention is a kind of preparation method of boron nitride coated carbon nanotube, comprising the following steps:

[0013] (1) For pretreatment of carbon nanotubes, the carbon nanotubes are refluxed with acid, washed with deionized water until neutral, and dried in vacuum for later use. Preferably, the pretreatment process of carbon nanotubes is: use concentrated HNO 3 or HNO 3 with H 2 SO 4 Mix and reflux for 8-24 hours at a temperature of 80-110°C, then filter, rinse with deionized water until neutral, and vacuum-dry at 80-100°C to finally obtain carbon nanotubes with -OH and -COOH on the surface, thereby Improve the dispersibility of carbon nanotubes in boric acid solution.

[0014] (2) Dissolving boric acid and urea in a solvent, ultrasonically dispersing the carbon nanotubes obtained in step (1) in the solution to prepare a boron nitride-coated carbon nanotube precursor solution, filtering, and drying in air to obtain a powder. Preferably, the sol...

Embodiment 1

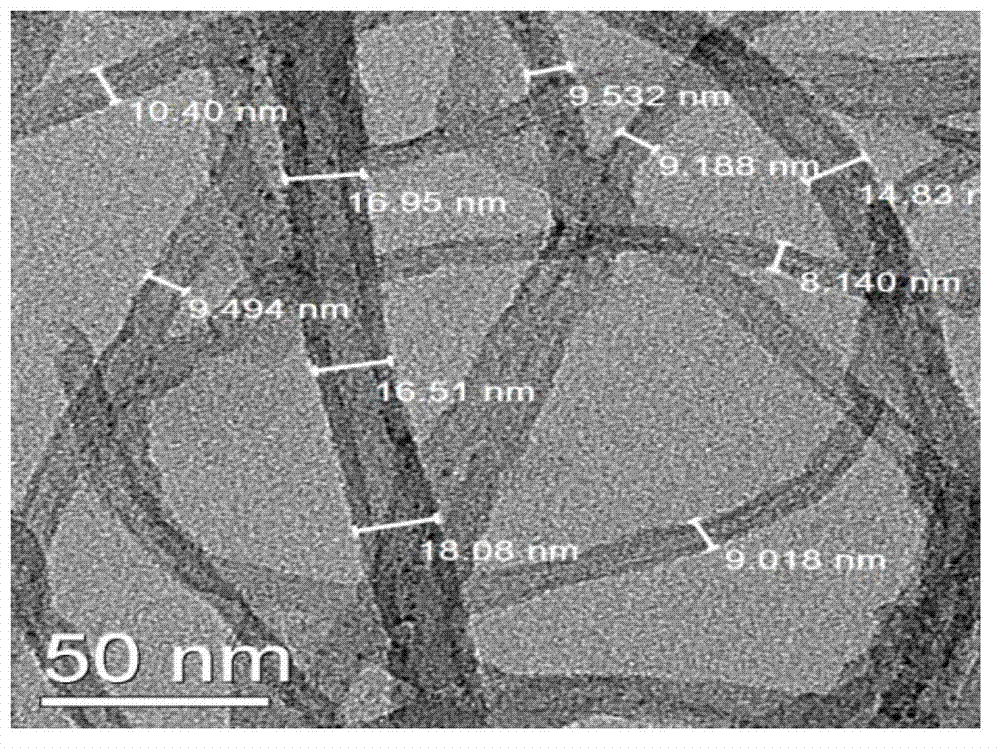

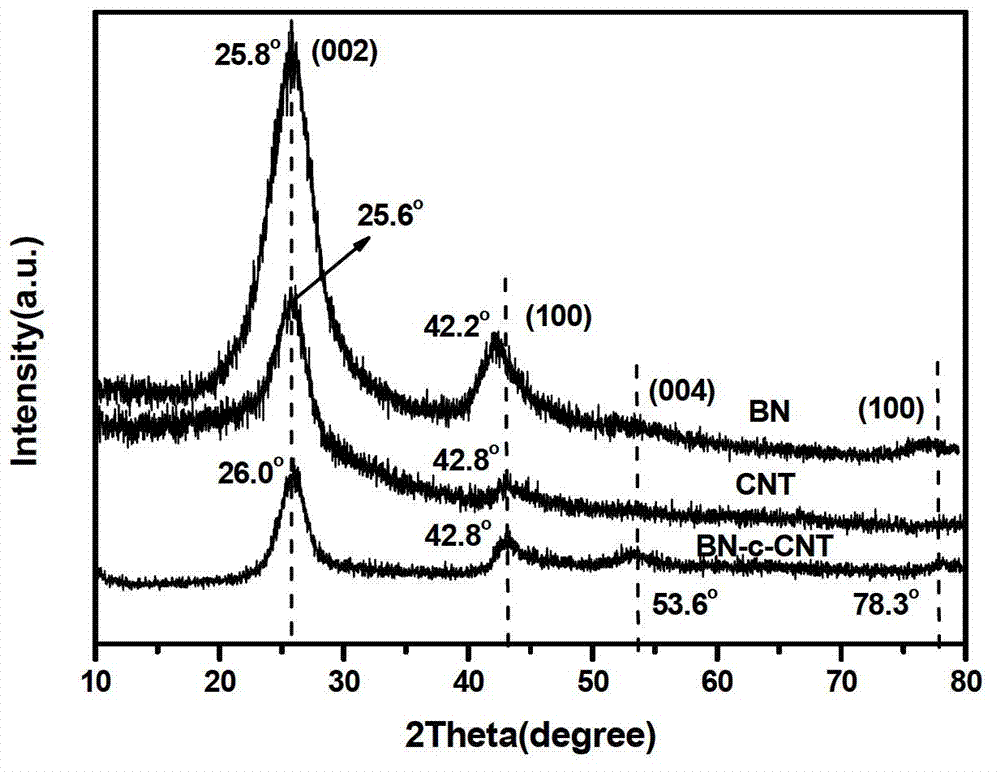

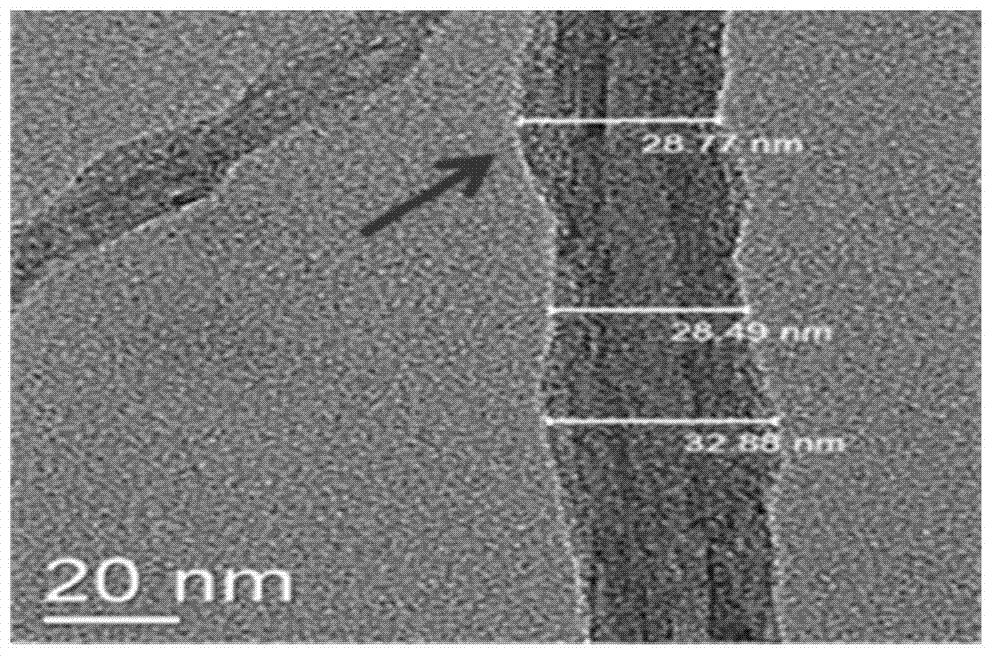

[0019] Step 1: Pretreatment of carbon nanotubes. The diameter of carbon nanotubes is 10-15nm. Weigh 1g of carbon nanotubes, pour them into a 250ml round bottom flask, and use concentrated HNO 3 Reflux for 24 hours at 110°C, filter, wash with deionized water several times until neutral, and then vacuum dry at 100°C for 12 hours for later use.

[0020] Step 2: Take by weighing 0.608g boric acid (H 3 BO 3 ), 7.087g urea (NH 2 -CO-NH 2 ), first H 3 BO 3 Pour it into 10ml of ethanol to dissolve it completely, then pour urea into the ethanol solution of boric acid, weigh 0.1g of oxidized carbon nanotubes, pour it into the saturated solution, and ultrasonically disperse it for 3 hours. The purpose is to make urea, boric acid and carbon nanotubes are uniformly dispersed, so that they are completely impregnated, then stirred at room temperature for 10 hours, filtered, and dried in the air for high temperature treatment.

[0021] Step 3: put the composite powder obtained in step 2...

Embodiment 2

[0024] Step 1: Pretreatment of carbon nanotubes. The diameter of carbon nanotubes is 10-15nm. Weigh 1g of carbon nanotubes, pour them into a 250ml round bottom flask, and use concentrated HNO 3 Reflux for 24 hours at 110°C, filter, wash with deionized water several times until neutral, and then vacuum dry at 100°C for 12 hours for later use.

[0025] Step 2: Take 0.608g boric acid (H 3 BO 3 ), 4.724g urea (NH 2 -CO-NH 2 ), first H 3 BO 3 Pour it into 15ml of ethanol to dissolve it completely, then pour urea into the ethanol solution of boric acid, weigh 0.05g of oxidized carbon nanotubes, pour it into the saturated solution, and ultrasonically disperse it for 2 hours. and carbon nanotubes are uniformly dispersed, so that they are completely impregnated, then stirred at room temperature for 10 hours, filtered, and dried in the air for high temperature treatment.

[0026] Step 3: put the composite powder obtained in step 2 into the porcelain boat, 2 Boron nitride-coated c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com