Silk specially used for painting and calligraphy and manufacturing method thereof

A silk, calligraphy and painting technology, applied in the field of carrier materials for calligraphy and painting, can solve the problems of difference in warp and weft growth, adverse effects of wetting on textile fabrics, easy torn, punctured or damaged, etc. Strong three-dimensional effect, simplify the mounting process, accelerate the effect of diffusion and penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiments 1 to 10 are specific embodiments of the special silk for painting and calligraphy of the present invention, wherein embodiment 1 is the best embodiment.

[0031] Example 1

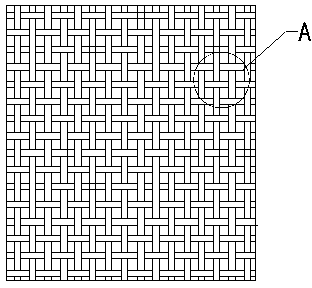

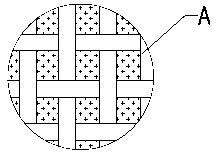

[0032] Silk layer 1 warp and weft raw materials are made of mulberry silk, silk layer 1 organizational form: untwisted plain silk electric spinning.

[0033] The lining layer 3 selects sandalwood fiber and rice straw fiber as raw material rice paper, and the content of sandalwood fiber is 60%.

[0034] In this embodiment, the special silk for calligraphy and painting is made by the following steps:

[0035] 1) Cut mulberry fiber and hemp fiber respectively, and the cut length is 3mm; 30 parts of glutinous rice starch, 17 parts of sodium carboxymethyl cellulose, 6 parts of γ-cyclodextrin, 0.8 parts of nano-titanium dioxide, and 4 parts of hemp fiber 12 parts of mulberry fiber, 0.13 part of fatty alcohol polyoxyethylene ether O-15 type, 0.07 part of sodium diacetate and stir and mix, a...

Embodiment 2

[0040] Silk layer 1 warp: mulberry silk; weft: tussah silk; fabric type: silk layer 1 is untwisted plain weave.

[0041] The lining layer 3 selects sandalwood fiber and rice straw fiber as the rice paper of raw material, and the content of sandalwood fiber is 80%.

[0042] In this embodiment, the special silk for calligraphy and painting is made by the following steps:

[0043]1) Cut mulberry fiber and hemp fiber respectively, and the cut length is 5mm; 35 parts of glutinous rice starch, 23 parts of carboxymethyl cellulose sodium, 7 parts of γ-cyclodextrin, 0.6 part of nano-titanium dioxide, and 4 parts of hemp fiber 16 parts of mulberry fiber, 0.1 part of fatty alcohol polyoxyethylene ether O-20 type, 0.12 part of sodium diacetate, stirred and mixed, added deionized water while stirring, and gradually raised the temperature to 40~60°C, and prepared a solution for later use;

[0044] 2) Add 0.1 part of polyvinyl acetate to 15~18 parts of ethanol with a content of 95~99.8% to ...

Embodiment 3

[0048] The warp thread of the real silk layer 1 is made of mulberry silk; the weft thread of the real silk layer 1 is made of tussah silk; the weave form of the real silk layer 1 is untwisted plain weave.

[0049] The liner 3 is made of hemp paper made of ramie fiber and flax fiber.

[0050] In this embodiment, the special silk for calligraphy and painting is made by the following steps:

[0051] 1) Cut mulberry fiber and hemp fiber respectively, and the cut length is 3mm; 29 parts of glutinous rice starch, 20 parts of sodium carboxymethyl cellulose, 6 parts of γ-cyclodextrin, 0.8 parts of nano-titanium dioxide, and 4 parts of hemp fiber 14 parts of mulberry fiber, 0.07 part of fatty alcohol polyoxyethylene ether O-15 type, 0.1 part of sodium diacetate and stir and mix, add deionized water while stirring, gradually heat up to 40~60°C, and prepare the solution for later use;

[0052] 2) Add 0.2 parts of polyvinyl acetate to 15-18 parts of ethanol with a content of 95-99.8% to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com