Composite material component unit with anti-delamination properties and composite material containing the unit

A composite component and component unit technology, applied in the field of fiber-reinforced layered composite structure, can solve the problems of difficult realization, high manufacturing cost, complicated process, etc., and achieve the effect of improving anti-delamination ability and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

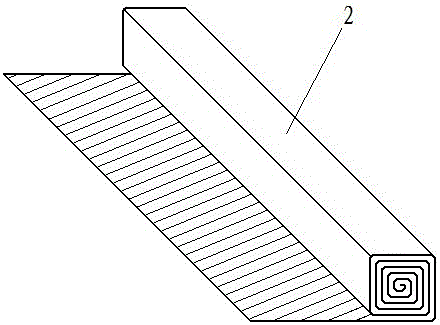

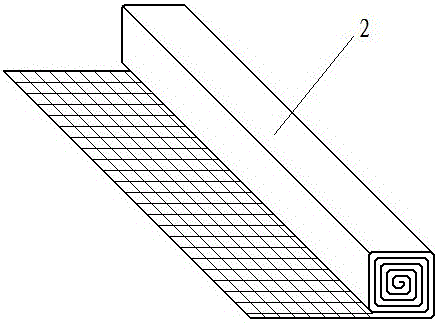

[0036] Such as Figure 1-Figure 15 Shown is a composite material component unit with anti-delamination properties. The component unit is composed of fiber layers arranged zigzagging along the two-dimensional direction in space, and has a fiber reinforcement effect in the thickness direction of the component.

[0037] Such as figure 1 and figure 2 As shown, the component unit is formed by continuous rolling of fiber layers to form a layer roll structure unit 2, and the fiber layers of the layer roll structure unit are arranged zigzagging along two-dimensional directions in space, that is, in the direction of the thick bottom along the X-axis and the Y-axis direction The upper layer is arranged in multiple layers and the fiber layers in the X-axis and Y-axis directions are arranged in a continuous zigzag, so that the member has a fiber-reinforced effect in the thickness direction.

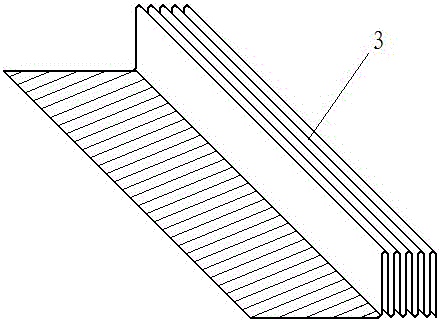

[0038] Such as image 3 and Figure 4 As shown, the component unit is a laminated structural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com