Technical wood and manufacture method thereof

A technical wood and wood technology, applied in the field of artificial wood and its preparation, can solve the problems of low density of artificial wood, easy to crack, and affect the wide use of artificial wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] 1. Dyeing treatment of veneer

[0078] 1) Rotate the fast-growing poplar wood into poplar veneers with a thickness of 0.8 mm, select a rotary-cut poplar veneer without holes, skins, and burrs. The moisture content of the veneer is 25-35% in the natural state, and the ;

[0079]2) Add wood staining agent, dyeing auxiliaries (Yuanming powder, penetrating agent, defoamer, etc.) -95°C; then soak the eucalyptus veneer in the dyeing solution of the dyeing machine, dye the veneer, check that the color meets the requirements, take out the veneer, clean and drain the dyeing solution on the surface; among them, according to the difference of the veneer The color is selected, the concentration of the dye solution is 0.3-0.5%, and the dyeing time is 3-8h, which is determined according to the thickness of the veneer. In the embodiment of the invention, the veneer is dyed into American cherry color as an example;

[0080] 3) Dry the filtered veneer with a dryer at a temperature of ...

Embodiment 2

[0115] In the veneer dyeing process, except that the thickness of the veneer is 1.5 mm and the moisture content is 20%, the rest is the same as in Example 1;

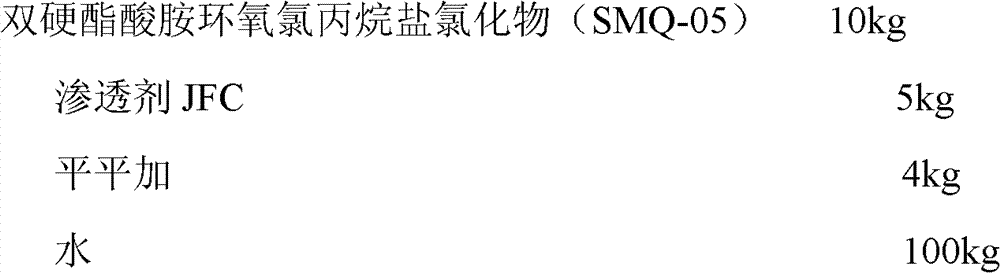

[0116] In the process of preparing wood softener, the weights of SMQ-05, penetrant JFC, Pingpingjia O and water are respectively 25kg, 2kg, 6kg and 100kg; the weight of the first batch of water accounts for 30% of the total water weight, and the first heating The temperature of heating up is 50 ℃, and the temperature of heating up for the second time is 70 ℃, all the other are identical with embodiment 1;

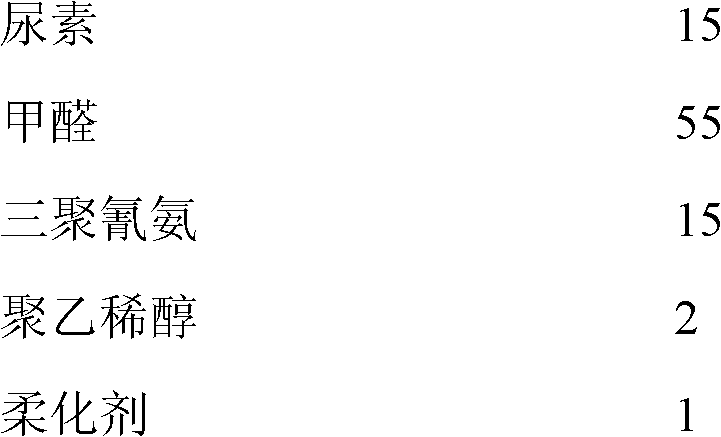

[0117] In the process of preparing the impregnation solution, except the weight of raw materials is as follows: the weights of urea, formaldehyde, melamine, polyvinyl alcohol, softener and triethanolamine are 200kg, 610kg, 190kg, 50kg, 30kg, 20kg respectively; the pH of the first stage of the reaction 7.5, the reaction temperature is 90 ℃, the reaction time is 25min, the amount of the first batch of urea accounts for...

Embodiment 3

[0124] In the veneer dyeing process, except that the thickness of the veneer is 1mm and the moisture content is 30%, the rest are the same as in Example 1;

[0125] The process of preparing wood softener is except that the weights of SMQ-05, penetrating agent JFC, flat plus O and water are respectively 15kg, 2kg, 4kg, and 100kg; 1 same;

[0126]In the process of preparing the impregnating solution, except that the weight of the raw materials is as follows: the weights of urea, formaldehyde, melamine, polyvinyl alcohol, softener and triethanolamine are respectively 250kg, 700kg, 250kg, 50kg, 30kg and 10kg; the pH of the first stage of the reaction is 7.8, the reaction temperature is 85°C, the reaction time is 20min, the amount of the first batch of urea accounts for 40% of the total amount of urea; the second stage of the reaction: when the second batch of urea is added, the pH value is 5.0, the reaction temperature is 85°C, the second batch of urea The viscosity of the two-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com