Selective doping method for solar cell based on reverse diffusion

A solar cell and reverse diffusion technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as reducing battery efficiency, reducing production efficiency, and increasing costs, reducing the steps to remove amorphous silicon films and improving production efficiency. , to ensure the effect of heavy doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

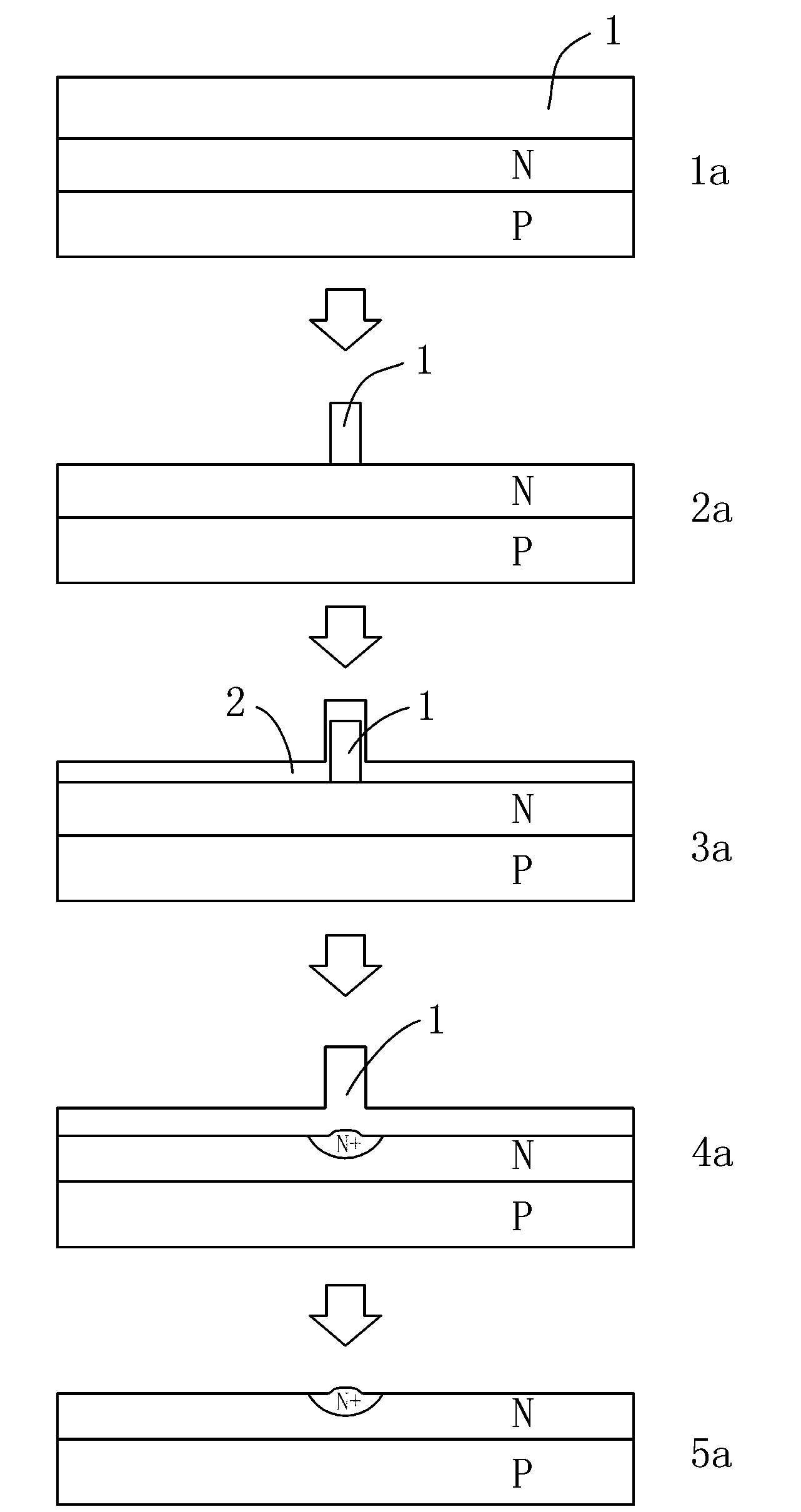

[0034] Such as figure 1 Shown is a schematic flow chart of the method for selective doping of solar cells based on reverse diffusion in the present invention, which specifically includes the following steps:

[0035] 1a. Place the P-type monocrystalline silicon wafer in a humid oxygen environment for high-temperature pre-diffusion, so that phosphorus element diffuses into the silicon wafer to form a PN junction. At the same time, a phosphosilicate glass layer 1 with a thickness of about 0.05 microns is formed on the silicon wafer surface. The concentration of phosphorus in the glass layer 1 is about 1e19 / cm 3 ;The process temperature of high temperature pre-diffusion is 1000°C, and the duration is 30 minutes;

[0036] 2a. Retain the phosphosilicate glass in the top electrode area by screen printing, and remove the phosphosilicate glass in other areas on the silicon wafer with hydrofluoric acid buffer;

[0037] 3a. Depositing an intrinsic amorphous silicon layer 2 with a thic...

Embodiment 2

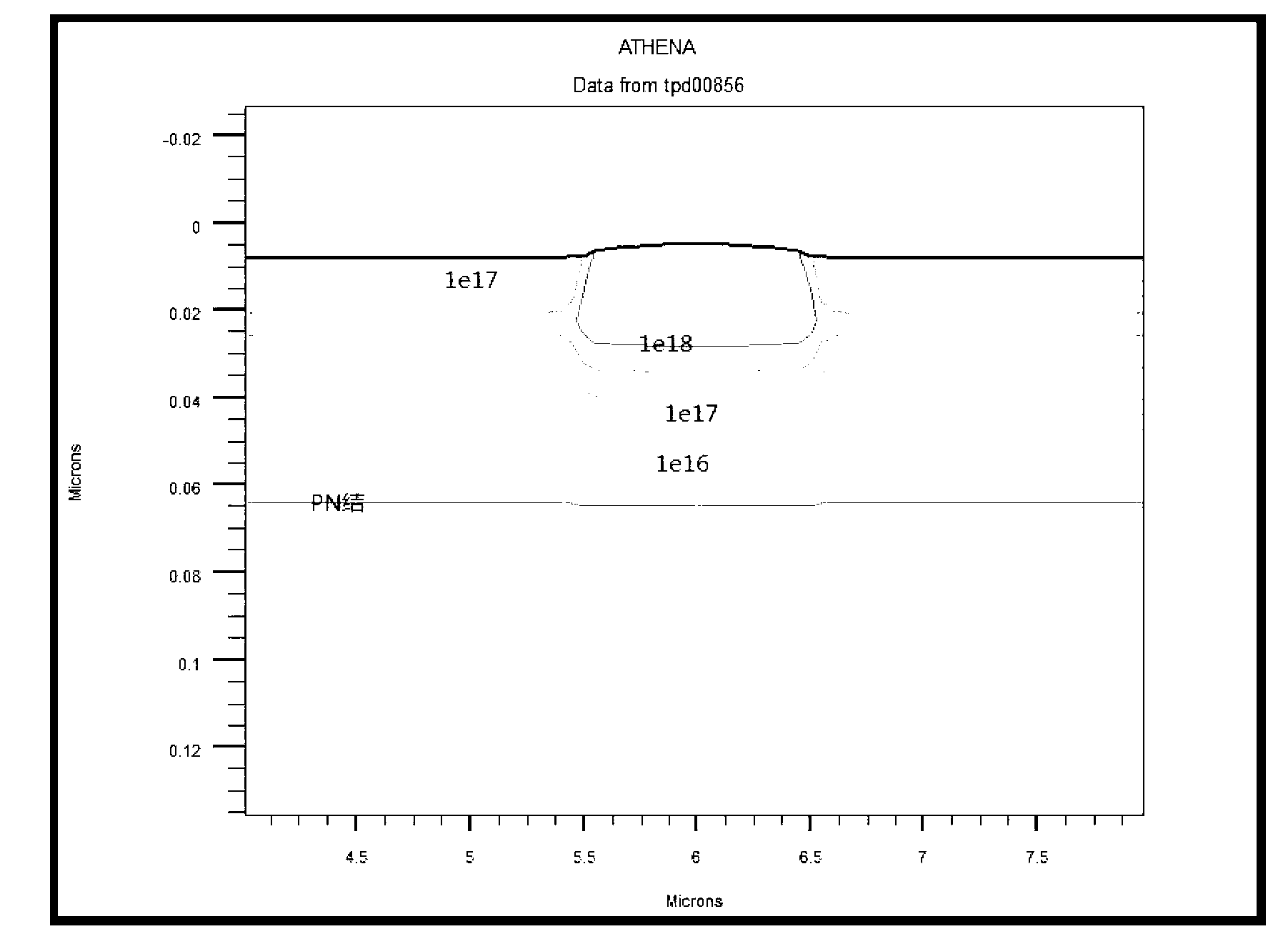

[0042] The steps of this example are the same as those of Example 1, the difference lies in the process parameters of high-temperature diffusion in dry oxygen environment in step 4a (the fourth step). In this example, the process temperature of high-temperature diffusion is 1000°C, and the duration is 5 minutes . After using the simulation software to simulate the second method of this embodiment, the impurities in the silicon wafer can be seen image 3 . The curves in the simulation result graph respectively represent the concentration of the doping element (phosphorus) and the position of the PN junction.

Embodiment 3

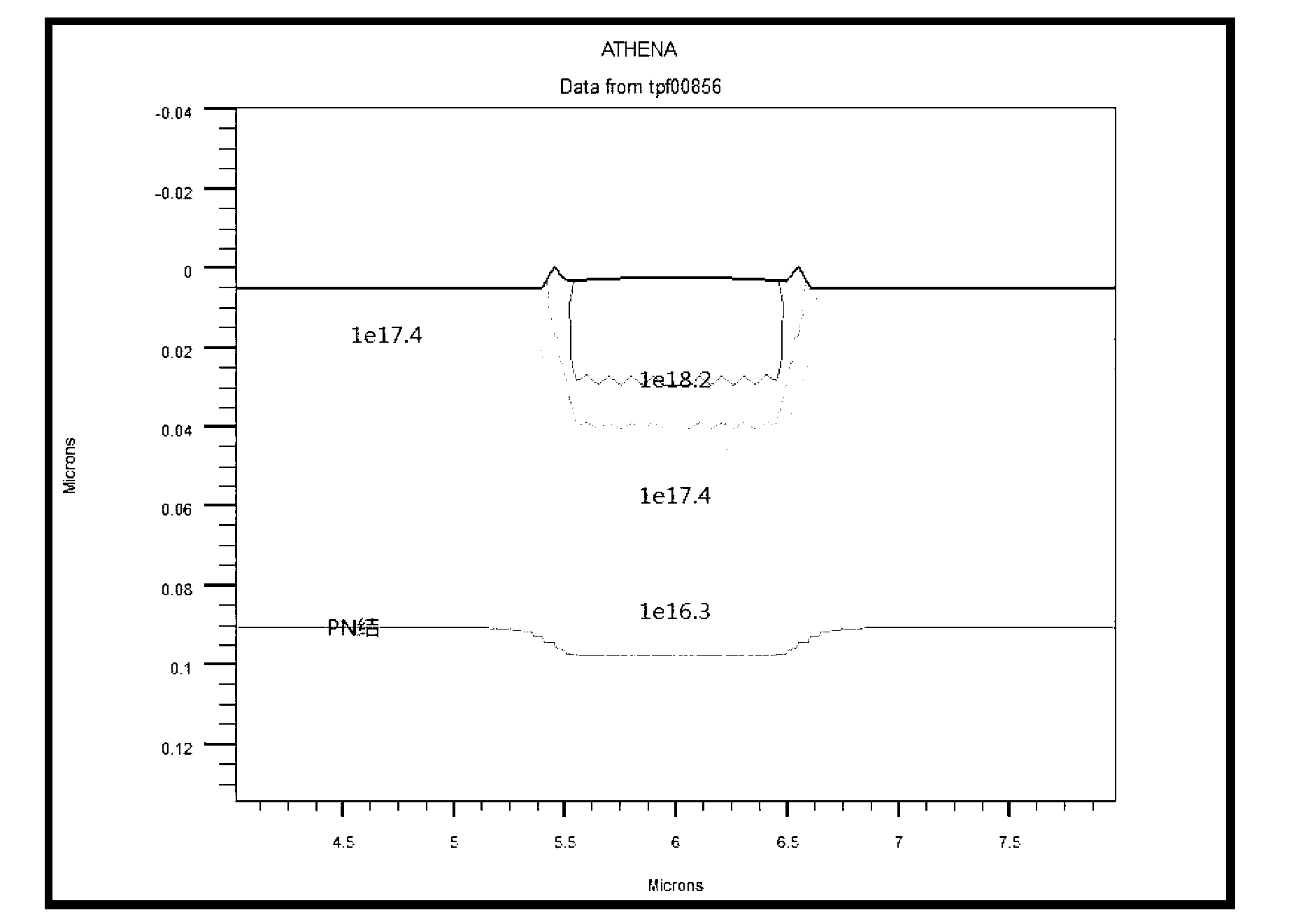

[0044] The steps of this example are the same as those of Example 1, the difference lies in the process parameters of high-temperature diffusion in dry oxygen environment in step 4a (the fourth step). In this example, the process temperature of high-temperature diffusion is 1100°C, and the duration is 2 minutes . After using the simulation software to simulate the third method of this embodiment, the impurities in the silicon wafer can be seen Figure 4 . The curves in the simulation result graph respectively represent the concentration of the doping element (phosphorus) and the position of the PN junction.

[0045]Comparing the three embodiments of the present invention, it can be seen from the simulation results that the PN junction of the battery is continuously deepened with the increase of the high-temperature diffusion temperature of the reverse diffusion process. The impurity concentration on the surface of the battery first increases and then decreases, but the impur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com