Phosphorescent organic electroluminescent device

A luminescent and electromechanical technology, applied in the field of organic electroluminescent devices, can solve the problems of cost increase, device efficiency attenuation, high doping concentration of phosphorescent materials, etc., and achieve the goal of improving stability, maintaining long life and high efficiency, and reducing doping concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

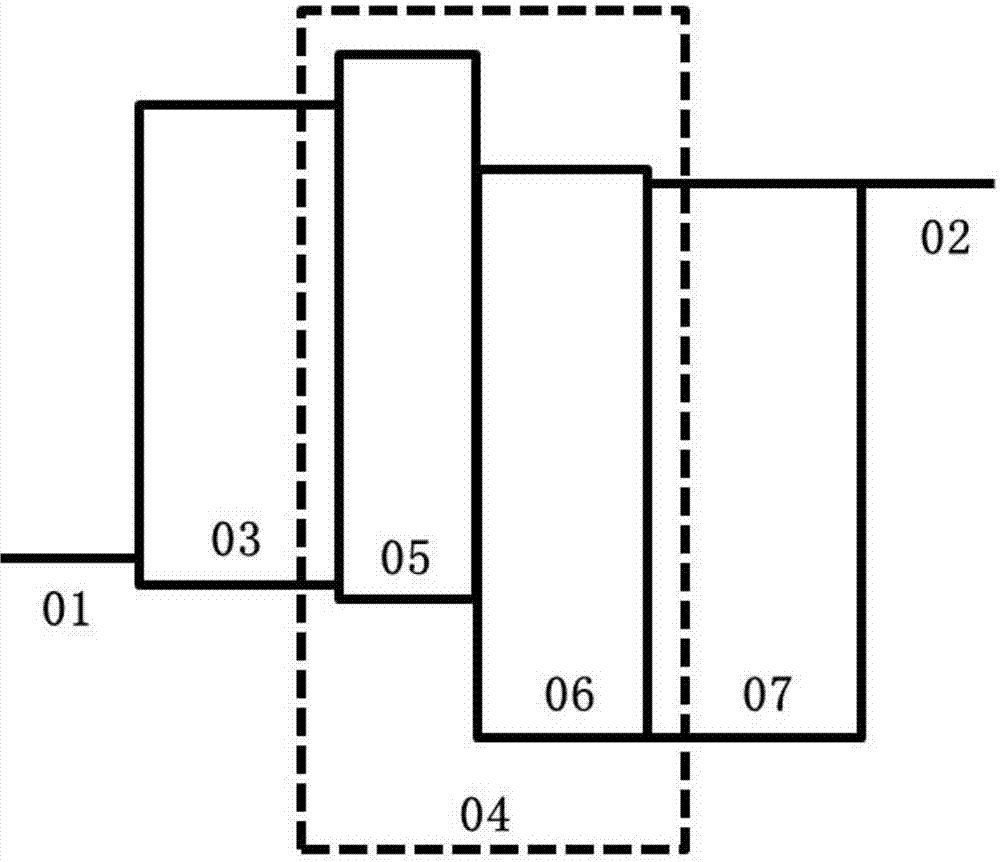

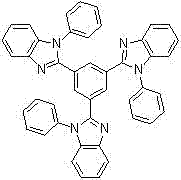

[0146] In this example, light-emitting devices with different thicknesses of the hole-transport material layer 05 and the electron-transport material layer 06 in the light-emitting layer were prepared. These devices have the following properties: figure 1 structure shown. Hole transport material layer 05 (composed of host material 2-5TCTA), electron transport material layer 06 (host material 1-8CzTrz, phosphorescent dye PO-01) of the light emitting layer. (The LUMO difference between the donor host and the acceptor host is greater than 0.3 eV, and the HOMO difference is greater than 0.2 eV; the first singlet energy level of the exciplex is higher than that of the phosphorescent dye.) Phosphorescent dye PO-01 The proportion in the light-emitting layer is 3wt%.

[0147] The device structure of this embodiment is as follows:

[0148] ITO (150nm) / NPB (40 nm) / hole transport material layer TCTA (10 nm) / electron transport material layer 1-8CzTrz+phosphorescent dye PO-01 (30nm) / Bphe...

Embodiment 2

[0169] The device structure of this embodiment is as follows:

[0170] ITO(150nm) / NPB(40nm) / TCTA(10nm) / CzTrz+1~10wt% phosphorescent dye PO-01(30nm) / Bphen(20nm) / LiF(0.5nm) / Al(150nm)

[0171] The proportion of phosphorescent dye PO-01 in the light-emitting layer is 1-10wt%.

[0172] In this embodiment, different doping concentrations of phosphorescent dyes are selected for experiments in the light-emitting layer, and the results shown in Table 2 are obtained.

[0173] Table 2

[0174] luminous layer Luminous efficiency (cd / A) Brightness (cd / m 2 )

[0175] It can be seen from Table 2 that when the doping concentration of the phosphorescent dye in the light-emitting layer is 3wt%, the external quantum efficiency and lifetime of the OLED device are both optimal.

Embodiment 3

[0177] In order to test the influence of the host material of the present invention on the performance of the organic electroluminescent device, this example prepared an organic electroluminescent device in the same manner as in Example 1 above. The structure of the light emitting device is as follows:

[0178] ITO (150nm) / NPB (40 nm) / hole transport material layer (material with hole transport ability) (10 nm) / electron transport material layer (material with electron transport ability: 3wt% phosphorescent dye) (30 nm ) / Bphen(20nm) / LiF(0.5nm) / Al(150nm)

[0179] The proportion of phosphorescent dye PO-01 in the light emitting layer is 3wt%.

[0180] The properties of the organic electroluminescent device are shown in Table 3 below:

[0181] table 3

[0182] device hole transport material layer electron transport material layer Luminous efficiency (cd / A) Brightness (cd / m 2 )

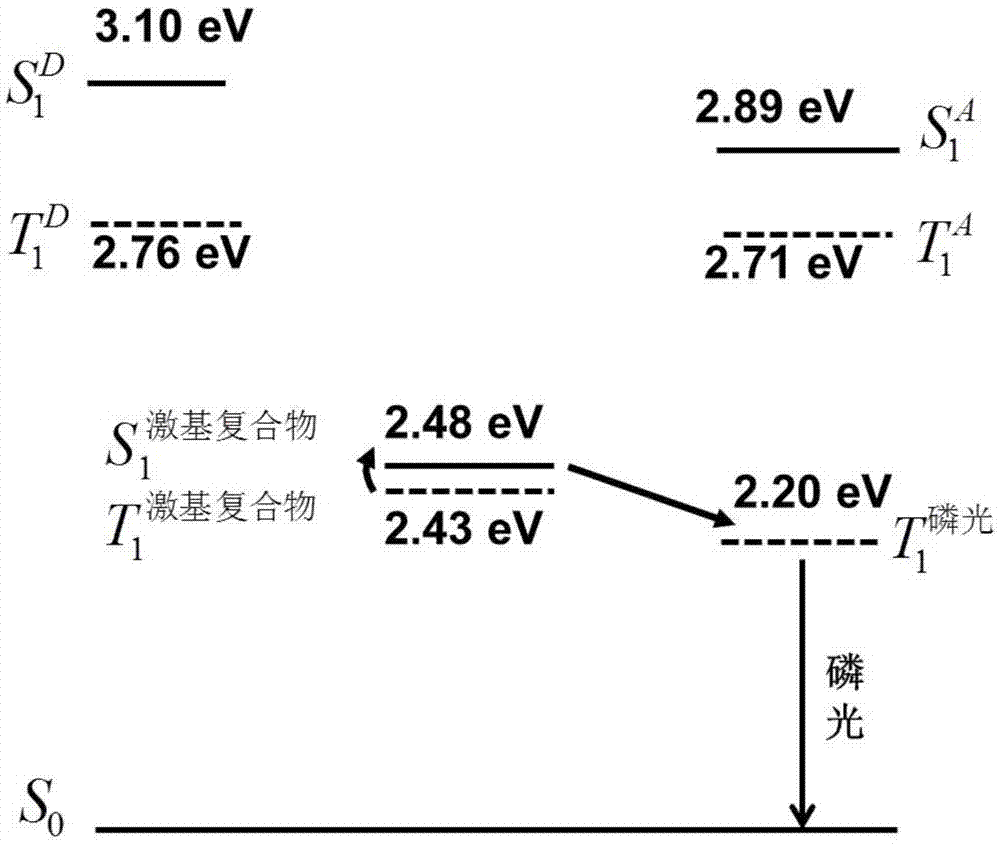

[0183] It can be seen from Table 3 that the exciplexes formed between the interfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com