A kind of high tenacity sound insulation composite material and preparation method thereof

A technology of composite materials and sound insulation materials, applied in the direction of coating, etc., can solve the problems of poor environmental protection and unsatisfactory sound insulation performance, and achieve the effects of convenient coloring, excellent mechanical properties, and good sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

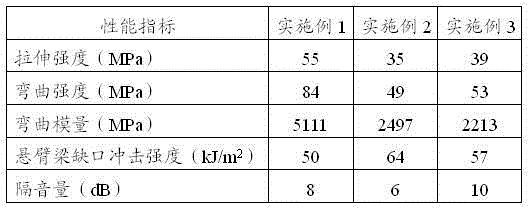

Embodiment 1

[0038] 46 parts by weight of polypropylene, 3 parts by weight of ethylene-acrylate-glycidyl methacrylate terpolymer, 0.4 parts by weight of polypropylene wax as a lubricant, 10100.2 parts by weight of antioxidant, and 1680.4 parts by weight of antioxidant in 180 Plasticized and melted at -200°C to obtain a polypropylene resin melt; the continuous polyethylene terephthalate fiber is drawn out from the creel, the tension is adjusted by the tension roller, and the melt is introduced into the impregnated die, and passed through the polypropylene resin. Acrylic resin melt impregnation, realize the dispersion and infiltration of fibers in the die head, control the fiber content to 50 parts by weight through the fiber outlet of the die head, after the organic fibers are completely infiltrated and cooled and solidified, cut into 10mm length by pelletizer The particles were obtained to obtain polyethylene terephthalate fiber toughened polypropylene composites.

[0039] 54.7 parts by we...

Embodiment 2

[0042] 67.4 parts by weight of polypropylene, 2 parts by weight of styrene-ethylene / butylene-styrene block copolymer, 10100.2 parts by weight of antioxidant, and 1680.4 parts by weight of antioxidant are plasticized and melted at a temperature of 180-220 ° C, The polypropylene resin melt is obtained; the continuous polyphenylene sulfide fiber is drawn out from the creel, the tension is adjusted by the tension roller, and the melt is impregnated into the die, and the polypropylene resin melt is impregnated to realize the dispersion of the fiber in the die. Infiltration, through the fiber outlet of the die head, the content of the fiber is controlled to 30 parts by weight. After the organic fiber is completely infiltrated and cooled and solidified, it is cut into particles with a length of 12mm by a pelletizer to obtain a polyphenylene sulfide fiber toughened polypropylene composite material. .

[0043] 59.7 parts by weight of polypropylene resin, 40 parts by weight of talcum po...

Embodiment 3

[0046] 57.2 parts by weight of polypropylene, 2 parts by weight of maleic anhydride grafted polypropylene, 0.2 parts by weight of lubricant calcium stearate, 10980.2 parts by weight of antioxidant, and 1680.4 parts by weight of antioxidant were molded at a temperature of 180-200 ° C. melted to obtain a polypropylene resin melt; the continuous nylon 66 fiber is drawn out from the creel, the tension is adjusted by a tension roller, and the melt is impregnated into the die head, and the polypropylene resin melt is impregnated to realize the dispersion of the fiber in the die head and infiltration, the content of the fiber controlled by the fiber outlet of the die head is 40 parts by weight, after the organic fiber is completely infiltrated and cooled and solidified, it is cut into particles with a length of 11 mm by a pelletizer to obtain a nylon 66 fiber toughened polypropylene composite material.

[0047] 49.7 parts by weight of polypropylene resin, 50 parts by weight of barium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com