Low-temperature stable storage method for polyamide acid glue liquid as well as refrigerating liquid composition

A polyamic acid glue solution and a storage method technology are applied in the field of high molecular weight polyamic acid stable storage method and ethylene glycol type freezing liquid composition, polyamic acid low temperature stable storage method and freezing liquid composition field, which can solve difficult problems. problems such as burning, safety production hidden dangers, equipment safety monitoring and management and maintenance costs increase, etc., to achieve the effects of low foam tendency, long stabilization time, and not easy to degrade and deteriorate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

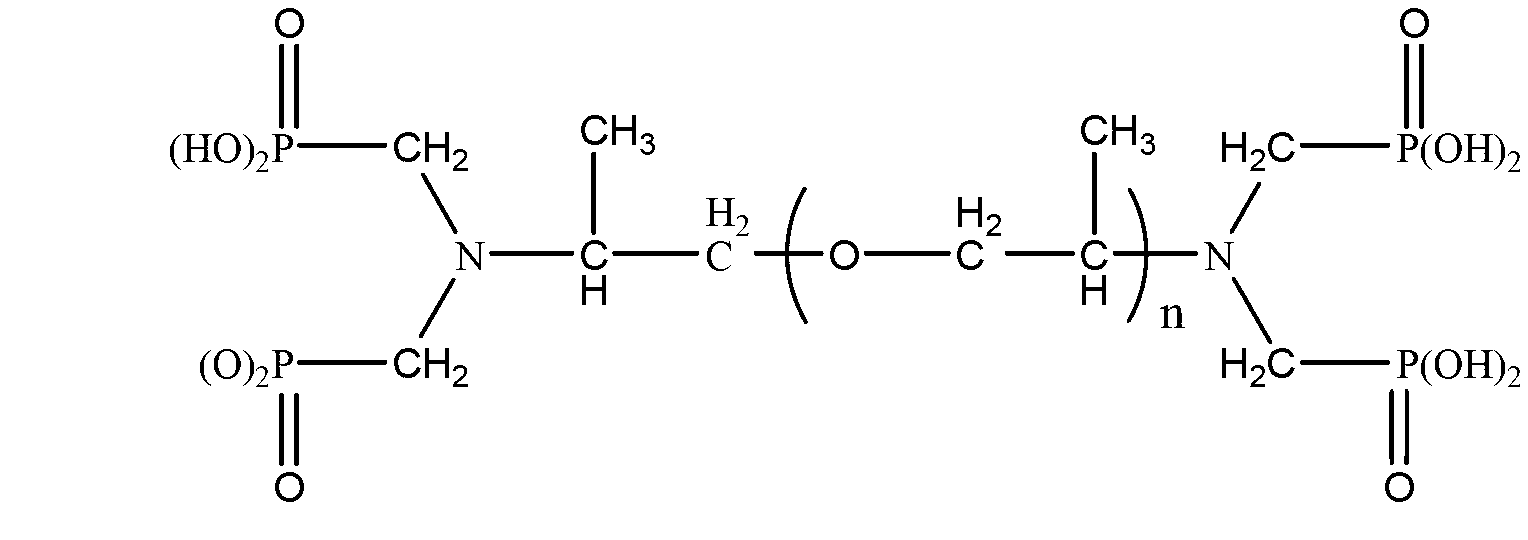

[0055] Add 8 kg of isoquinoline or 1.3 kg of octaploid hydrogen-containing siloxane to a storage tank containing 1000 kg of high molecular weight polyamic acid solution with a viscosity of 245,100 centipoise. The temperature of the polyamic acid solution in the storage tank is -15°C. Use a high-speed disperser to disperse and stir at 2200-2500 rpm for 120s, filter and vacuum defoam, and pump it into a heat-insulated hollow jacketed low-temperature storage tank for storage at -20°C. In the jacket, the ethylene glycol refrigerant of formula 1 is used for refrigeration and insulation. The specific weight percentages of each component of the refrigerant are: demineralized water 60.015%, ethylene glycol 34%, 2-ethylhexanoic acid 4%, ethylenediamine Tetramethylene phosphonic acid 0.3%, benzotriazole 0.4%, molybdate 0.3%, sodium benzoate 0.035%, hydroxyethylene diphosphonic acid 0.3%, polyaminopolyether phosphate 0.35%, hydrolyzed maleic acid Anhydride 0.3%.

Embodiment 2

[0057] Add 13 kg of isoquinoline or 0.8 kg of octaploid hydrogen-containing siloxane to a storage tank containing 1000 kg of high-molecular-weight polyamic acid solution with a viscosity of 236,000 centipoise. The temperature of the polyamic acid solution in the storage tank is -20°C. Use a high-speed disperser at 2200-2500 rpm to disperse and stir for 60 seconds, filter and vacuum defoam, and then pump it into a heat-insulated hollow jacketed low-temperature storage tank for storage at -15°C. The jacket is refrigerated and insulated with the ethylene glycol refrigerant of Formula 2. The specific weight percentages of each component of the refrigerant are: demineralized water 66.4%, ethylene glycol 29%, vanillin 0.75%, furfural 0.75%, hexamethylene 0.2% tetramine, 0.25% methyl benzotriazole, 0.55% S-carboxyethyl thiosuccinic acid, 1.1% polyacrylic acid, 0.9% polyepoxy succinic acid, 2-phosphonic acid butane-1, 2,4-Tricarboxylic acid 0.1%.

Embodiment 3

[0059] Add 10 kg of isoquinoline or 1 kg of octaploid hydrogen-containing siloxane to a storage tank containing 1000 kg of high-molecular-weight polyamic acid solution with a viscosity of 218,700 centipoise. The temperature of the polyamic acid solution in the storage tank is -25 ° C. Use Disperse and stir at 2200-2500 rpm for 100 seconds with a high-speed disperser. After filtration and vacuum defoaming, pump it into a heat-insulated hollow jacketed low-temperature storage tank for storage at -25°C. The jacket is refrigerated and insulated with the ethylene glycol refrigerant of Formula 1. The specific weight percentages of each component of the refrigerant are: demineralized water 58.015%, ethylene glycol 36%, 2-ethylhexanoic acid 4%, ethylenediamine Tetramethylene phosphonic acid 0.3%, benzotriazole 0.4%, molybdate 0.3%, sodium benzoate 0.035%, hydroxyethylene diphosphonic acid 0.3%, polyaminopolyether phosphate 0.35%, hydrolyzed maleic acid Anhydride 0.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com