Raw material preparation method of dry method reconstituted tobacco

A technology for reconstituted tobacco leaves and raw materials, which is applied in the preparation of tobacco, tobacco, and applications. It can solve the problems of not involving the content of the preparation method of extracting slag dry fibers, serious loss of tobacco aroma, and low production efficiency, and achieve flexible formulation and application methods. , Easy to control the dryness, and the effect of increasing the spreading rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

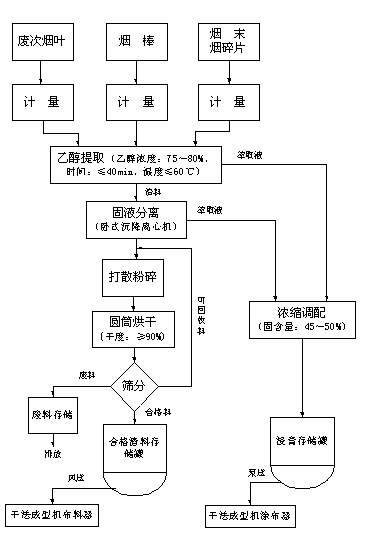

Method used

Image

Examples

Embodiment 1

[0019] 1. Weigh the tobacco powder, broken stalks, and debris raw materials according to the weight ratio of 1:2:1, then send them into a sealed reaction kettle, soak them in 75% ethanol for 5 minutes, and then continue to stir for 40 minutes. Minutes, during the stirring process, the temperature of the feed liquid remains at 60 degrees, and the stirring speed is 15 rpm;

[0020] 2. Take out the liquid in the reactor and release the slag;

[0021] 3. Send the slag to the horizontal sedimentation separator, further separate the residual extract in the slag, and then discharge the slag to ensure that the dryness of the discharged slag is ≥ 70%;

[0022] 4. Transport the slag to the dispersing and screening machine for dispersing, crushing and screening. The qualified slag will enter the next process, and the unqualified slag will be sent to the crusher for crushing before secondary screening. The final qualified slag enters the next process, and the screen mesh is 80-100 mesh. ...

Embodiment 2

[0025] 1. Weigh the tobacco powder, broken stalks, and debris raw materials according to the weight ratio of 2:1:2, then put them into a sealed reaction kettle, soak them in 75% ethanol for 5 minutes, and then stir continuously for 30 minutes. Minutes, during the stirring process, the temperature of the feed liquid is maintained at 50 degrees, and the stirring speed is 10 rpm;

[0026] 2. Take out the liquid in the reactor and release the slag;

[0027] Subsequent procedures are the same as 3-5 of Embodiment 1.

[0028] Since the extract prepared by the alcohol extraction method can retain the original components of the tobacco to the greatest extent, the slag after the alcohol extraction has a high bulkiness after drying, and the base sheet made on the dry papermaking reconstituted tobacco leaf production equipment is loose. The thickness is high, so it is beneficial to increase the coating rate of the substrate and increase the filling value of the reconstituted tobacco lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com