Papermaking coating, making method of coated paper using papermaking coating and coated paper

A coated paper and coating technology, applied in paper coating, papermaking, textiles and papermaking, etc., can solve the problems of uneven coating thickness and poor microscopic distribution uniformity of the surface layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

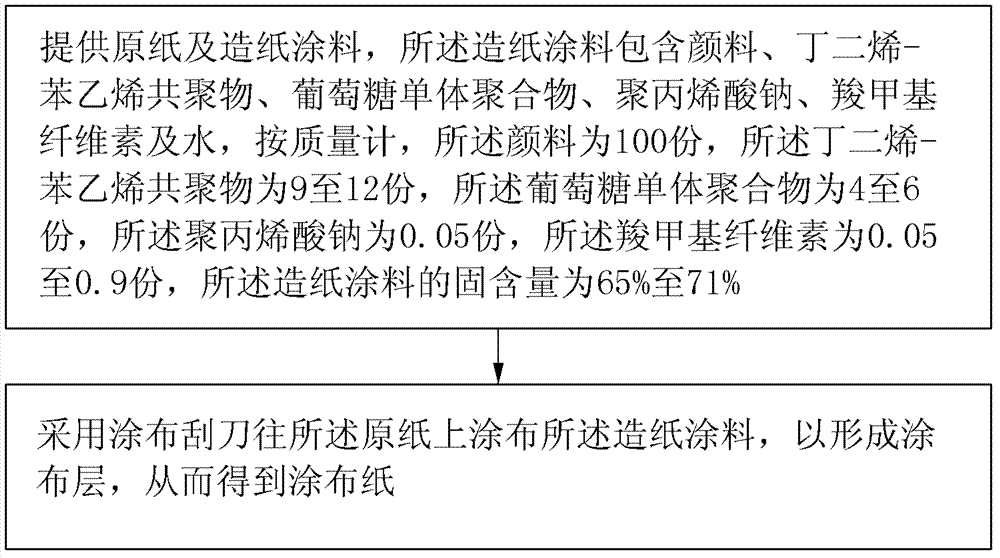

[0016] The papermaking coating provided by the present invention, the coated paper using the papermaking coating and the manufacturing method of the coated paper provided by the present invention will be further described in detail with reference to the accompanying drawings and multiple embodiments.

[0017] The invention provides a paper coating, which comprises pigment, butadiene-styrene copolymer, glucose monomer polymer, sodium polyacrylate, carboxymethyl cellulose, wet strength agent, lubricant and water.

[0018] The pigment is 100 parts by mass. The pigment is mainly calcium carbonate. The calcium carbonate includes a first type of calcium carbonate and a second type of calcium carbonate. In the first type of calcium carbonate, the content of particles with a particle size of less than 2 microns accounts for 65%. In the second type of calcium carbonate, the content of particles with a particle size of less than 2 microns accounts for 95%. In terms of mass, in 100 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com