Thin film capacitor applicable to DC-link occasion

A technology of film capacitors and capacitors, which is applied in the direction of film/thick film capacitors, stacked capacitors, fixed capacitor electrodes, etc., can solve the problems of unrealizable, small capacitance, large volume, etc., to ensure overcurrent capability and reduce volume , high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

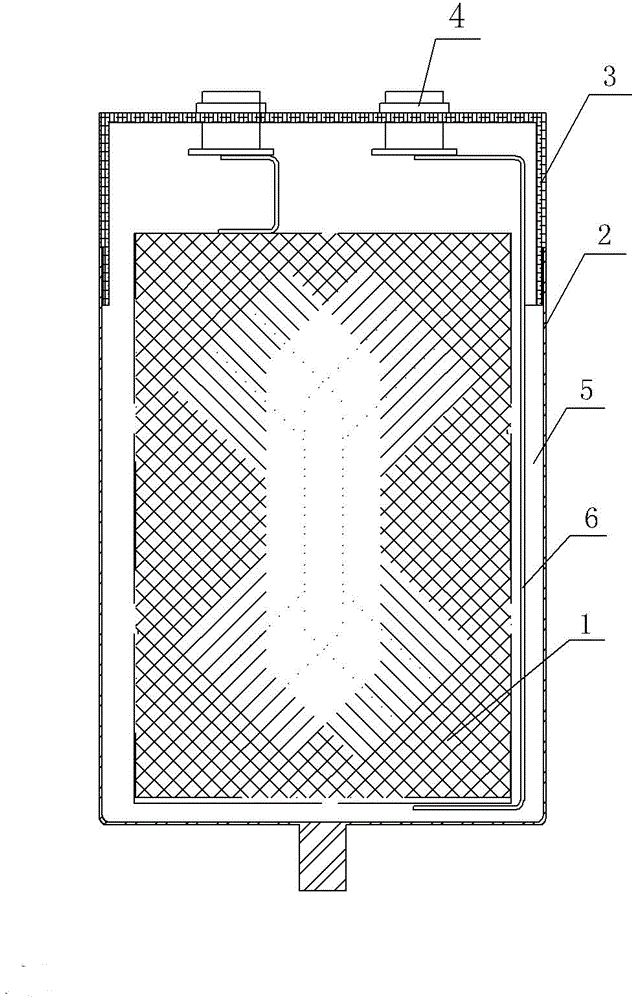

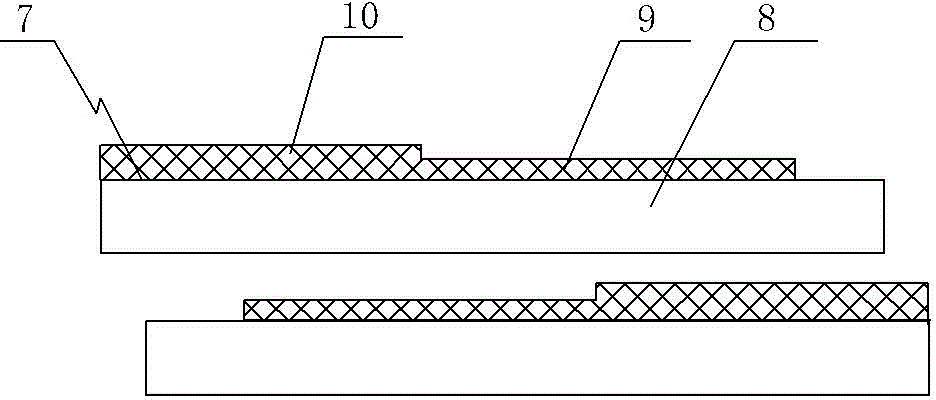

[0013] See figure 1 , figure 2 As shown, a film capacitor applied to DC-link occasions includes a capacitor core 1, an aluminum casing 2, a plastic positioning cover 3, a lead end 4, a potting material 5, and a connecting copper strip 6. The capacitor core 1 is composed of The connecting copper strip 6 is connected to the lead-out end 4. The interior of the aluminum shell 2 is sealed and insulated with epoxy resin as the potting material 5. The lead-out end 4 and the aluminum shell 2 are insulated by a plastic positioning cover 3. The capacitor core 1 is made of metallized polypropylene The film 7 is wound, and the metallized polypropylene film 7 includes a polypropylene film medium 8 and a capacitor plate, the capacitor plate is a metal coating 9 evaporated on the polypropylene film medium 8, and the polypropylene film medium 8 has a thickness of 3 ~15um, the thickness of the metal coating 9 is 30~100nm; the edge of the metal coating 9 is coated with an alloy thickening reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com