Corrosion-resistant self-centering bridge pier structure easy for seismic rehabilitation

A self-centering and corrosion-resistant technology, used in bridges, bridge parts, bridge construction, etc., can solve problems such as easy corrosion, and achieve the effect of improving the corrosion resistance of bridge piers, reducing repair work, and reducing residual deformation and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

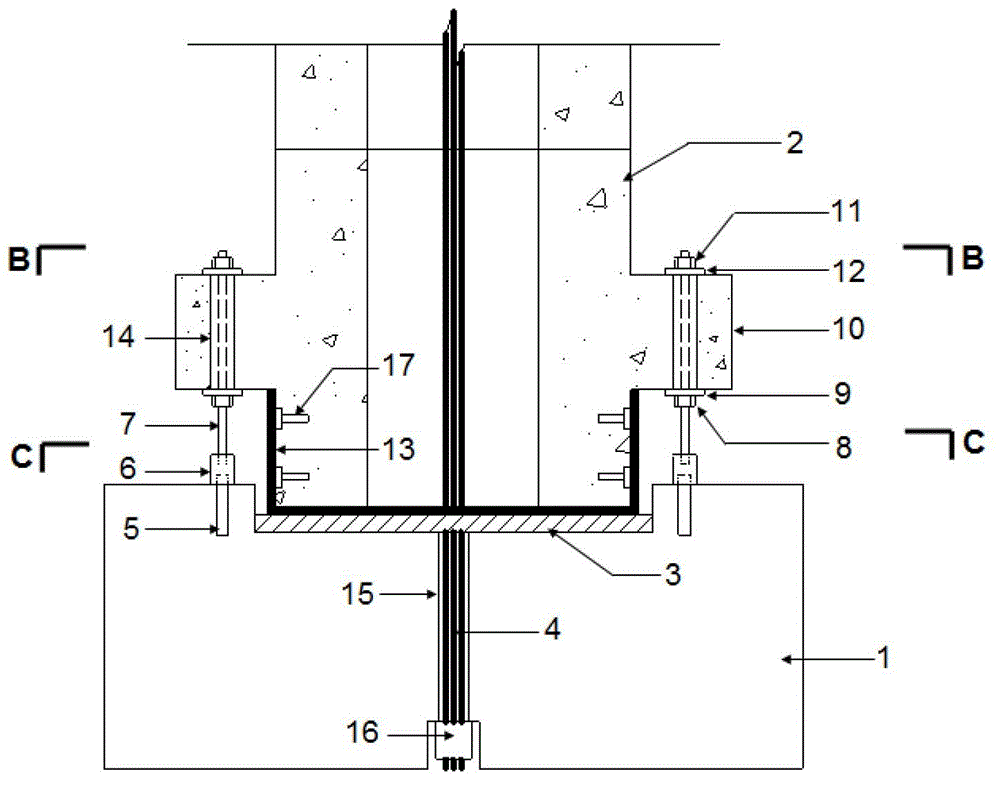

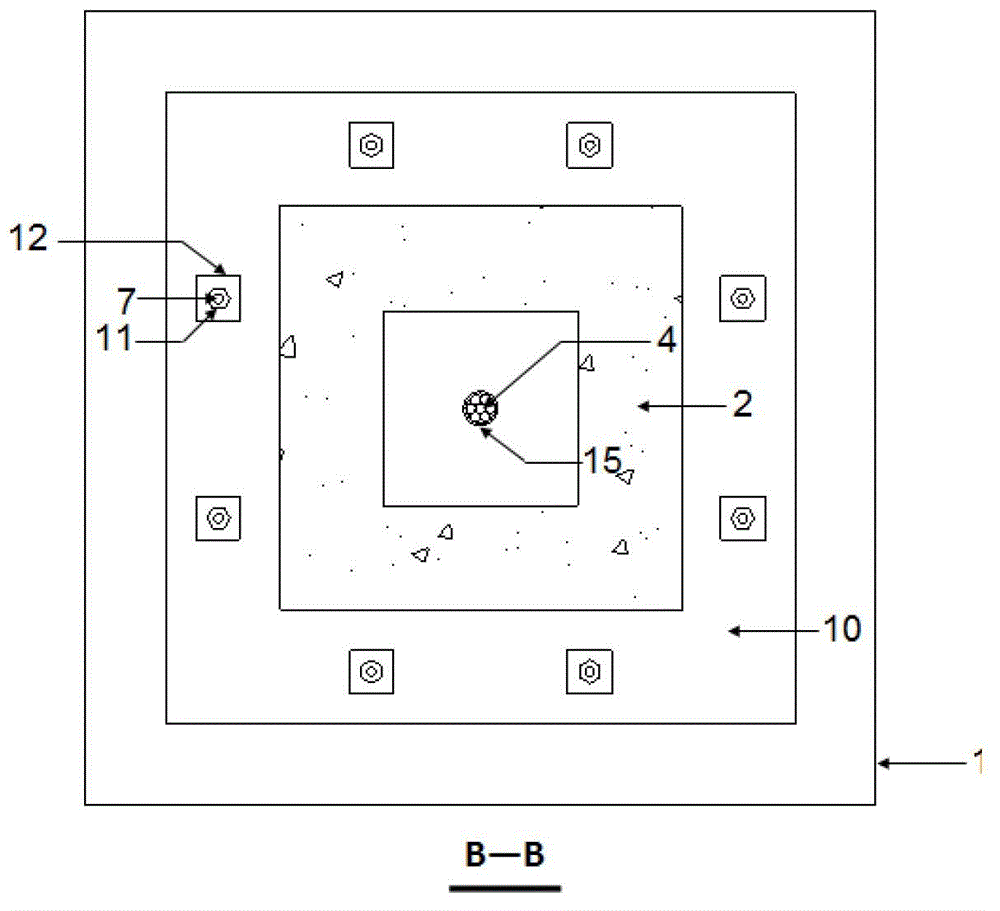

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

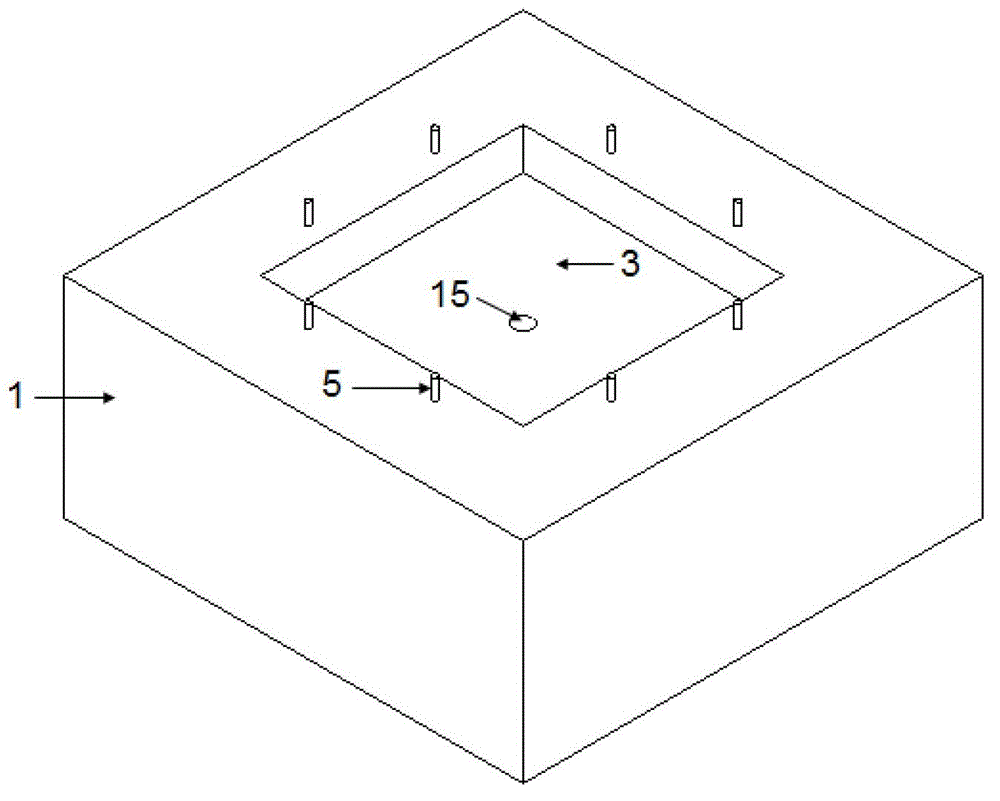

[0026] like Figure 1-5 As shown, a self-centering pier structure that is easy to repair after the earthquake and is corrosion-resistant, including concrete cap 1, prefabricated pier segment 2, pre-embedded FRP slab 3, post-tensioned prestressed FRP reinforcement 4, and pre-embedded reinforcement of the cap 5. FRP connecting sleeve 6. Anti-rust energy-dissipating rib 7. Nut 8 on the lower side of the corbel. 9 Backing plate on the lower side of the corbel. 10 on the corbel. Nut 11 on the upper side of the corbel. Sleeve 13, corbel reserved channel 14, platform reserved channel 15, anchor 16 and shear pin 17.

[0027] figure 1 Among them, the top surface of the concrete cap 1 is partially recessed to place the prefabricated pier segment 2 , and a tunnel 15 is reserved in the concrete cap 1 for passing through the post-tensioned prestressed FRP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com