Aramid fiber dispersion liquid and dispersion method and static sealing material of aramid fiber

A technology of aramid fiber and dispersion liquid, which is applied in the field of aramid fiber, can solve the problems that the dispersion effect of aramid fiber dispersion liquid needs to be improved, achieve good adsorption and suspension characteristics, prevent curling and bending, and reduce surface tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

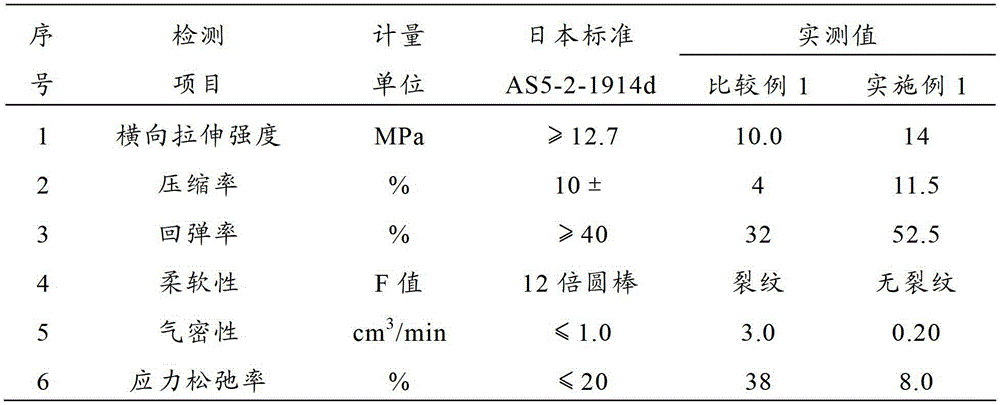

Embodiment 1

[0088] Dissolving the silicone surfactant and polyethylene oxide in xylene by stirring to obtain a mixed solution of the silicone surfactant and polyethylene oxide, wherein the silicone surfactant has a structure of formula (II), and the organic The mass concentration of silicon surfactant and polyethylene oxide is 0.1%, and the mass ratio of the two is 10%:90%;

[0089] [(CH 3 ) 3 N) 2 Si(CH 3 ) 2 ]Cl(II);

[0090] The mixed solution of silicone surfactant and polyethylene oxide is placed in an oiling machine, and under the conveyance of a constant pressure pump, the aramid fiber traveling on the production line is immersed online, and the traveling speed of the aramid fiber is 12m / min. Aramid fiber dispersion liquid was obtained.

[0091] Dry the fluororubber at 60°C for 24 hours.

[0092] 32wt% of dried fluorine rubber, 24wt% of aramid fiber dispersion, 33wt% of mica powder, 5wt% of modifier TSC30, 1.5wt% of sulfur, 1.6wt% of zinc oxide, 1.4wt% of Antiaging agent 40...

Embodiment 2

[0104] Dissolving the silicone surfactant and polyethylene oxide in xylene by stirring to obtain a mixed solution of the silicone surfactant and polyethylene oxide, wherein the silicone surfactant has a structure of formula (III), and the organic The mass concentration of silicon surfactant and polyethylene oxide is 1%, and the mass ratio of the two is 30%:70%;

[0105] [(CH 3 ) 3 N) 2 Si(CH 3 ) 2 ]Br(III);

[0106] The mixed solution of the silicone surfactant and polyethylene oxide is placed in an oiling machine, and under the delivery of a constant pressure pump, the aramid fiber traveling on the production line is immersed online, and the traveling speed of the aramid fiber is 20m / min. Aramid fiber dispersion liquid was obtained.

[0107] Dry the nitrile rubber at 50°C for 30 hours.

[0108] With 32wt% dried nitrile rubber, 25wt% aramid fiber dispersion, 30wt% white carbon black, 3wt% clay, 4wt% modifier TSC30, 1.6wt% sulfur, 1.6wt% Zinc oxide, 1.4wt% anti-aging ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com