Preparation method for graphene/aramid fibre 1414 nano-fibre composite membrane

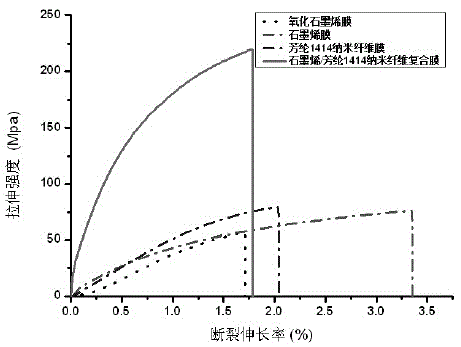

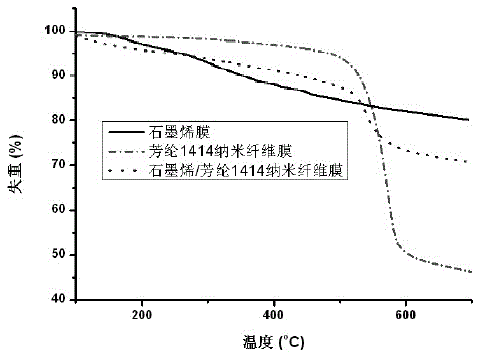

A technology of nanofibers and graphene, which is applied in the field of preparation of nanocomposite materials, can solve the problems of limited application and processing, difficult dissolution and dispersion, etc., and achieve the effects of improved Young's modulus, excellent mechanical properties, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

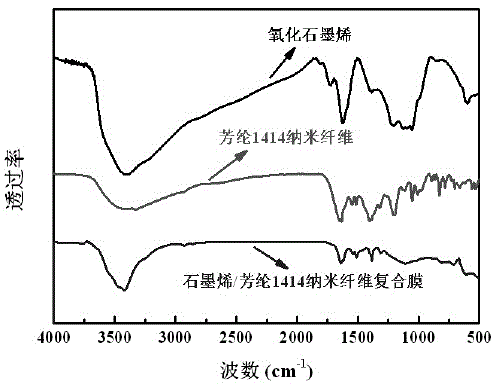

[0021] In a 500 ml beaker, first add 20 ml of prepared aramid 1414 nanofibers in dimethyl sulfoxide (2 mg / mL), then slowly add 8.0 ml of graphene oxide in dimethyl sulfoxide (5 mg / ml), magnetic stirring reaction at room temperature for 30 min to obtain a flocculent precipitate of graphene oxide / aramid 1414 nanofiber composite. After the reaction, the mixed solution was separated by centrifugation in a high-speed centrifuge (7000 rpm), and the lower layer of sediment was removed and dispersed in 20 ml of deionized water. After being dispersed by ultrasonication for 15 min, it was poured into a sand core filter device and used The graphene oxide / aramid fiber 1414 nanofiber composite filter cake was obtained by vacuum filtration with a 0.22 micron vinylidene fluoride filter membrane. The filter cake was dried in an oven at 80°C for 48 hours and then the film was removed. The obtained graphene oxide / aramid fiber Put the 1414 nanofiber composite membrane in hydroiodic acid, react a...

Embodiment 2

[0025] In a 500 ml beaker, first add 20 ml of prepared aramid 1414 nanofibers in dimethyl sulfoxide solution (2 mg / mL), then slowly add 16.0 ml of graphene oxide in dimethyl sulfoxide solution (5 mg / ml), magnetic stirring reaction at room temperature for 30 min to obtain a flocculent precipitate of graphene oxide / aramid 1414 nanofiber composite. After the reaction, the mixed solution was separated by centrifugation (7000 rpm) in a high-speed centrifuge, and the lower layer of sediment was removed and dispersed in 20 ml of deionized water. The graphene oxide / aramid 1414 nanofiber composite filter cake was obtained by vacuum filtration with a 0.22-micron vinylidene fluoride filter membrane. The filter cake was dried in an oven at 80°C for 48 hours and then the film was removed. The obtained graphene oxide / aramid fiber Put the 1414 nanofiber composite membrane in hydroiodic acid, react at 80 °C for 2 hours, take it out after the reaction and soak it in sodium carbonate with a mas...

Embodiment 3

[0027]In a 500 ml beaker, first add 20 ml of prepared aramid 1414 nanofibers in dimethyl sulfoxide (2 mg / mL), then slowly add 24.0 ml of graphene oxide in dimethyl sulfoxide (5 mg / ml), magnetic stirring reaction at room temperature for 30 min to obtain a flocculent precipitate of graphene oxide / aramid 1414 nanofiber composite. After the reaction, the mixed solution was separated by centrifugation in a high-speed centrifuge (7000 rpm), and the lower layer of sediment was removed and dispersed in 20 ml of deionized water. After being dispersed by ultrasonication for 15 min, it was poured into a sand core filter device and used The graphene oxide / aramid fiber 1414 nanofiber composite filter cake was obtained by vacuum filtration with a 0.22 micron vinylidene fluoride filter membrane. The filter cake was dried in an oven at 80°C for 48 hours and then the film was removed. The obtained graphene oxide / aramid fiber Put the 1414 nanofiber composite membrane in hydroiodic acid, react a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com