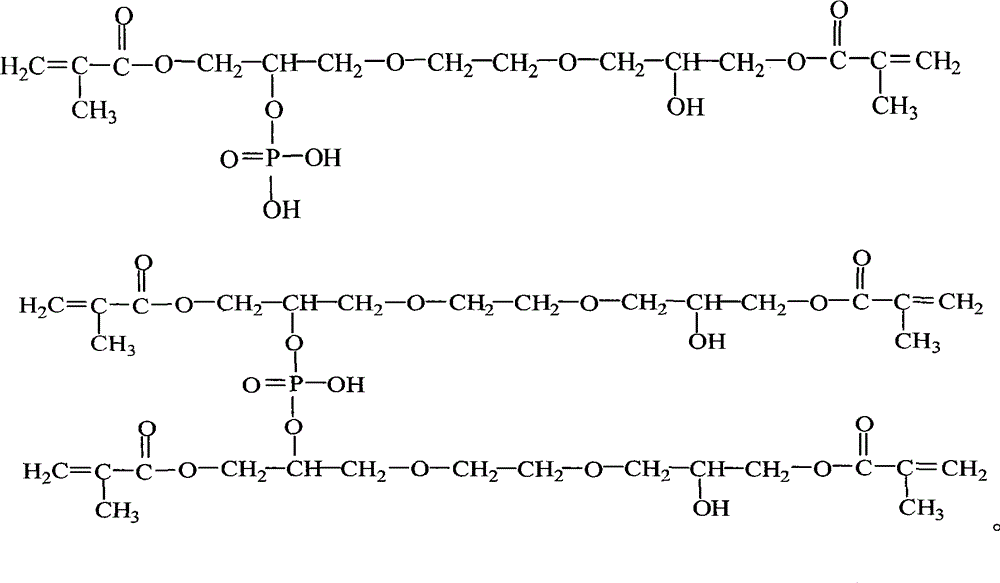

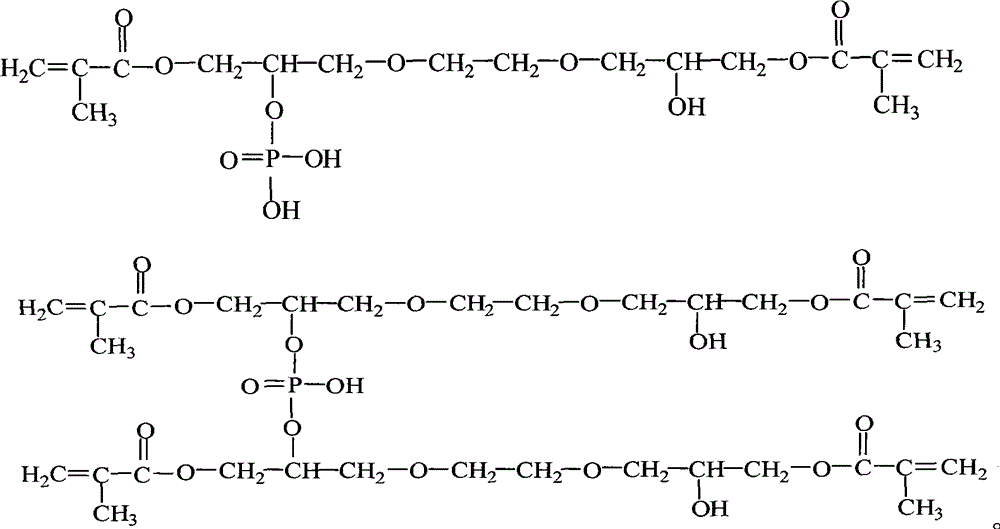

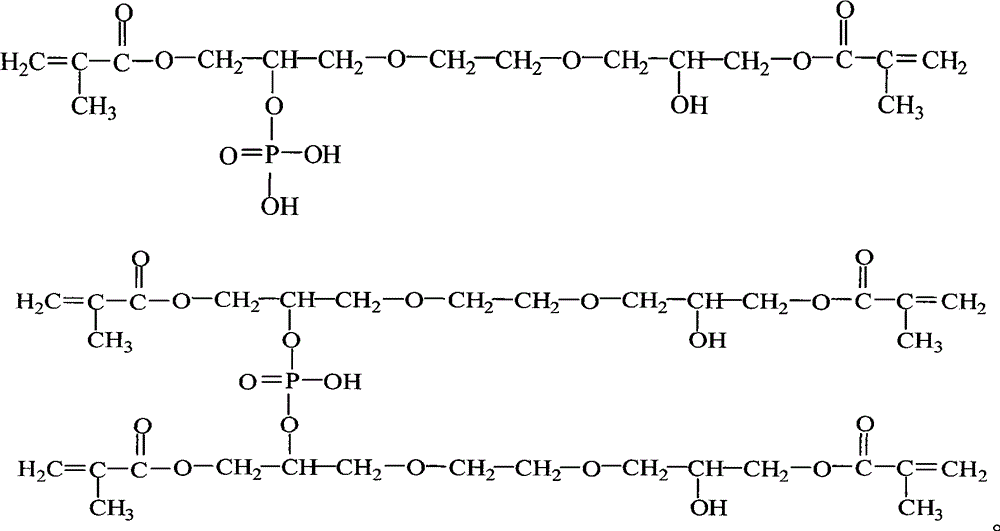

Ethylene glycol diglycidyl ether dimethacrylate organic phosphate and synthetic method thereof

A technology of bis-methacrylate phosphate and bis-methacrylate, applied in the direction of phosphorus organic compounds, can solve the problems of resin tolerance, strong corrosion, harsh production conditions, etc., to improve adhesion and adhesion. Strong, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 100g of ethylene glycol diglycidyl ether, 1.6g of triphenylphosphine, and 0.6g of p-hydroxyanisole into a reaction kettle equipped with cooling and heating devices and mechanical stirring, and slowly add 95g of methacrylic acid at a temperature below 50°C After the addition, the temperature was raised, and the reaction temperature was controlled at 100-110° C. after 6 hours of reaction. After the reaction, the product is cooled to below 30°C to obtain ethylene glycol diglycidyl ether dimethacrylate. Slowly add 26g of phosphorus pentoxide into the reaction kettle, control the temperature below 50°C, raise the temperature after the addition, control the reaction temperature at 75-90°C for 6 hours, cool down after the reaction to obtain the product. The product is light yellow, with a kinematic viscosity (25°C) of 280 mPa·s, a tetrafunctional content of over 62%, and an acid value of 130 mgKOH / g.

Embodiment 2

[0025] Add 100g of ethylene glycol diglycidyl ether, 1.8g of N,N-dimethylbenzylamine, and 0.6g of p-hydroxyanisole into a reaction kettle equipped with cooling and heating devices and mechanical stirring, and slowly Add 90 g of methacrylic acid, heat up after the addition, and control the reaction temperature at 100-110° C. for 8 hours. After the reaction, the product is cooled to below 30°C to obtain ethylene glycol diglycidyl ether dimethacrylate. Slowly add 25g of phosphorus pentoxide into the reaction kettle, control the temperature below 50°C, raise the temperature after the addition, control the reaction temperature at 75-90°C for 6 hours, cool down after the reaction to obtain the product. The product is light yellow, with a kinematic viscosity (25°C) of 270 mPa·s, a four-functionality content of over 60%, and an acid value of 128 mgKOH / g.

Embodiment 3

[0027] Add 60Kg of ethylene glycol diglycidyl ether, 1Kg of triphenylphosphine, and 0.5Kg of p-hydroxyanisole into a reaction kettle equipped with cooling and heating devices and mechanical stirring. Slowly add 57Kg of methacrylic acid at a temperature below 50°C. After the addition, the temperature was raised, and the reaction temperature was controlled at 100-110° C. after 7 hours of reaction. After the reaction, the product is cooled to below 30°C to obtain ethylene glycol diglycidyl ether dimethacrylate. Then slowly add 16Kg of phosphorus pentoxide into the reaction kettle, control the temperature below 50°C, raise the temperature after the addition, control the reaction temperature at 75-90°C for 6 hours, cool down after the reaction to obtain the product. The product is light yellow, with a kinematic viscosity (25°C) of 275 mPa·s, a four-functionality content of over 61%, and an acid value of 135 mgKOH / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com