Liquid crystal alignment agent, method for forming liquid crystal alignment film, and liquid crystal display element

A liquid crystal alignment agent, a technology for liquid crystal alignment, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve the problem of not having UV resistance, and achieve good pretilt angle performance, display quality is not deteriorated, and high UV resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

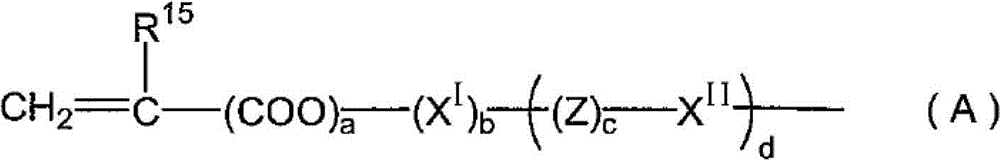

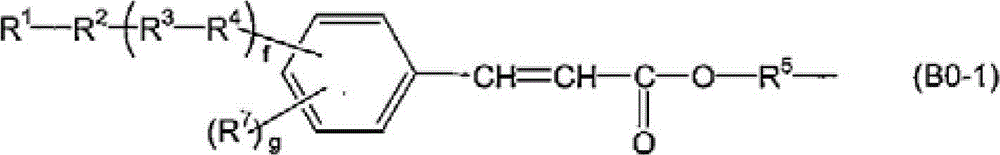

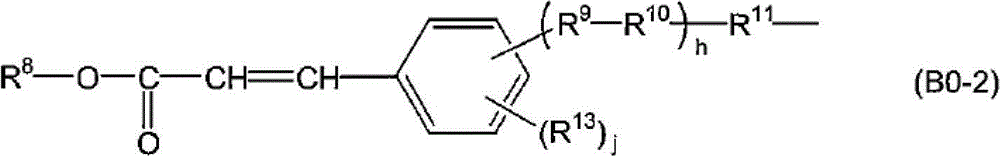

Method used

Image

Examples

example

[0199] Hereinafter, the present invention will be described more specifically by way of examples, but the present invention is not limited by these examples.

[0200] Hereinafter, the weight average molecular weight of polyorganosiloxane and the solution viscosity of polyamic acid were measured by the following method.

[0201] [Weight average molecular weight]

[0202] The weight-average molecular weight of polyorganosiloxane was determined based on the results of gel permeation chromatography under the following conditions using the following apparatus, and obtained a polystyrene-equivalent value using monodisperse polystyrene as a standard substance.

[0203] Measuring device: manufactured by Tosoh Corporation, model "8120-GPC"

[0204] Column: manufactured by Tosoh Corporation, "TSKgelGRCXLII"

[0205] Solvent: THF

[0206] Sample concentration: 5% by weight

[0207] Sample injection volume: 100μL

[0208] Column temperature: 40°C

[0209] Column pressure: 68kgf / cm ...

Synthetic example A-1

[0214] 13.9 g of oxalic acid and 19.5 g of ethanol were put into a reaction container equipped with a stirrer, a thermometer, a dropping funnel, and a reflux condenser, and stirred to prepare an ethanol solution of oxalic acid. Next, this solution was heated to 70 degreeC in nitrogen atmosphere, and the mixture containing 15.1 g of tetraethoxysilanes and 1.6 g of vinyltriethoxysilanes was dripped at this as a raw material silane compound. After completion|finish of dripping, the temperature of 70 degreeC was maintained for 6 hours, and polycondensation reaction was performed. After completion of the reaction, it was cooled to 25° C., and 40.0 g of butyl cellosolve was added to obtain a solution containing polyorganosiloxane (A-1) as polyorganosiloxane (I).

[0215] The weight average molecular weight Mw of the polyorganosiloxane (A-1) contained in this solution was 12,000.

[0216] Synthesis Example A-2 to Synthesis Example A-10

[0217] In the above-mentioned synthesis exam...

Synthetic example G-1

[0245] 99 g of 2-(3,4-epoxycyclohexyl)ethyltrimethoxysilane as a raw material silane compound and 99 g of methylisomethoxysilane as a solvent were charged into a reaction vessel equipped with a stirrer, a thermometer, a dropping funnel, and a reflux condenser. 500 g of butyl ketone and 10 g of triethylamine as a catalyst were mixed at room temperature. Next, after 100 g of deionized water was dripped there over 30 minutes using the dropping funnel, reaction was performed for 6 hours while stirring under reflux at 80°C. After the reaction, the organic layer was taken out, washed with a 0.2% by weight aqueous solution of ammonium nitrate until the washed water became neutral, and then the solvent and water were distilled off under reduced pressure to obtain a viscous transparent liquid. Polyorganosiloxane containing epoxy groups.

[0246] For the epoxy-containing polyorganosiloxane 1 As a result of the H-NMR analysis, a peak based on the epoxy group was obtained at around chem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com