Environment-friendly plate material compounded by organic silicon modified epoxy resin and waste circuit board non-metallic powder

An epoxy resin, modified technology, applied in the field of environmental protection board, can solve the problems of brittleness, poor impact resistance and stress cracking ability, limitation, non-environmental protection, etc., to achieve good toughness, good strength, good water and heat resistance The effect of acid and alkali corrosiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

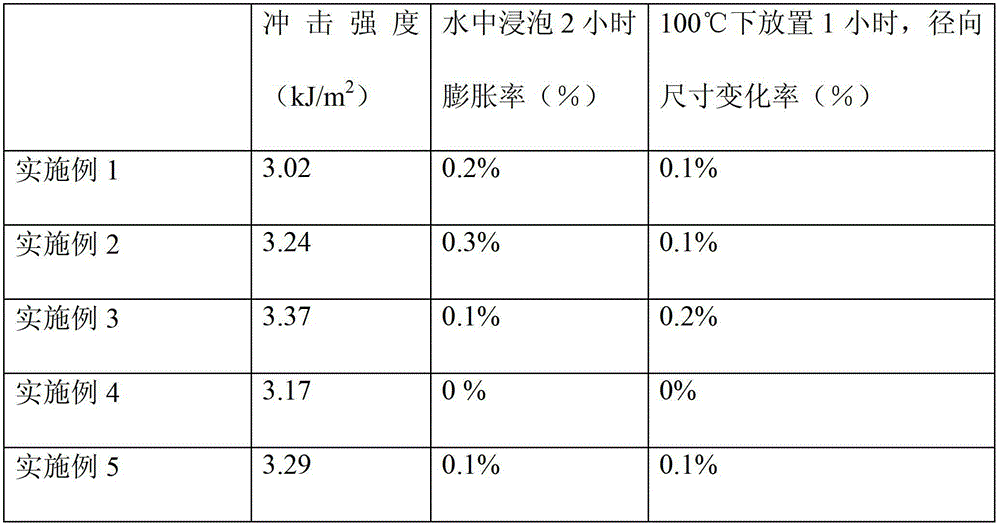

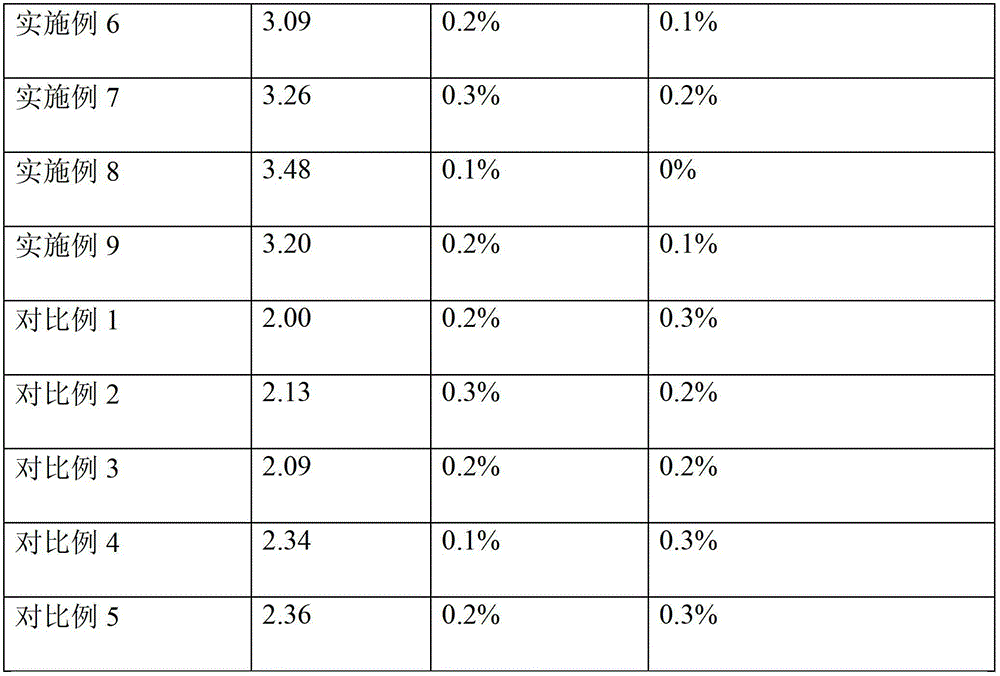

Examples

preparation example

[0023] Preparation example: preparation method of dimethyldichlorosilane modified epoxy resin

[0024] The method comprises the steps of:

[0025] Dissolve 1 mole of epoxy resin (EO 15-20, molecular weight 2000-3000) in toluene, slowly add 5-15 moles of dimethyldichlorosilane to the toluene solution dissolved in epoxy resin until no Until a large amount of aerosol is generated; 2) Let the solution continue to react for 1 hour. The whole reaction process is stirred by a stirring device. After the dimethyldichlorosilane and epoxy resin are fully absorbed, use triethylamine to absorb the HCl generated during the reaction. 3) After the reaction is completed, wash the solution several times with distilled water to remove the quaternary ammonium salt, then distill under reduced pressure to remove the toluene to obtain a dimethyldichlorosilane-modified epoxy resin.

Embodiment 1

[0026] Embodiment 1: The environmentally friendly board synthesized by using dimethyldichlorosilane modified epoxy resin and waste circuit board powder of the present invention includes the following components by weight ratio: 25 parts obtained in the preparation example. Epoxy resin, 75 parts waste circuit board powder. Practice has proved that the material mixed with each component under this formula can produce qualified environmental protection boards synthesized by using dimethyldichlorosilane modified epoxy resin and waste circuit board powder.

Embodiment 2

[0027] Embodiment 2: The environmentally friendly board synthesized by using dimethyldichlorosilane modified epoxy resin and waste circuit board powder of the present invention includes the following components by weight ratio: 20 parts of dimethyldichlorosilane modified Epoxy resin, 80 parts waste circuit board powder. Practice has proved that the material mixed with each component under this formula can produce qualified environmental protection boards synthesized by using dimethyldichlorosilane modified epoxy resin and waste circuit board powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com