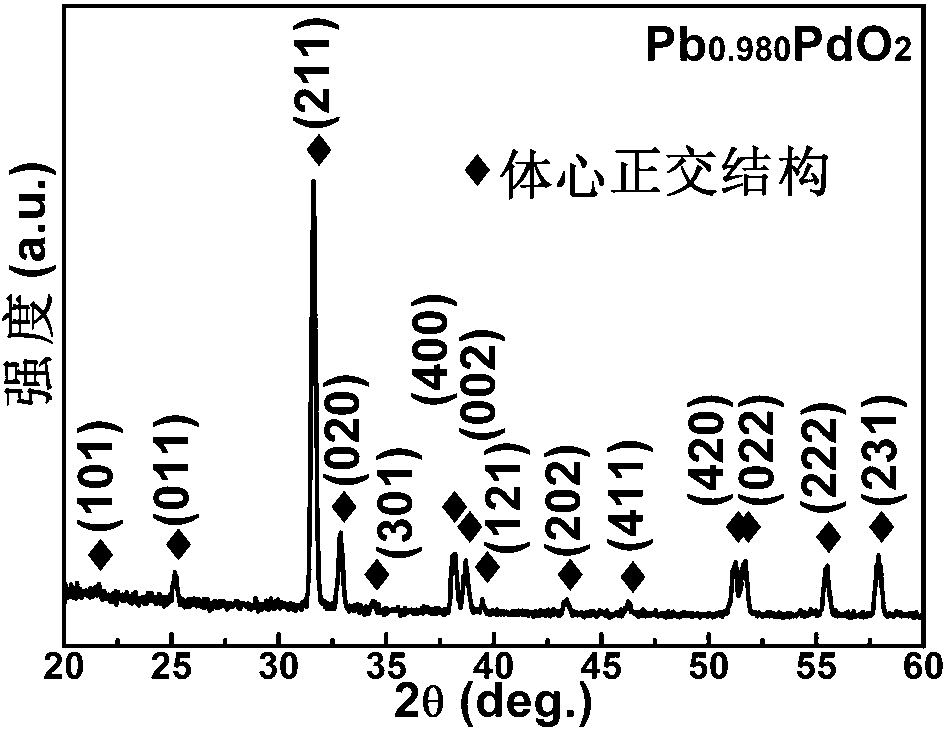

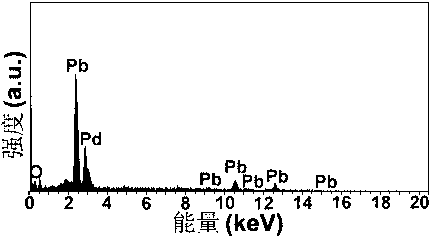

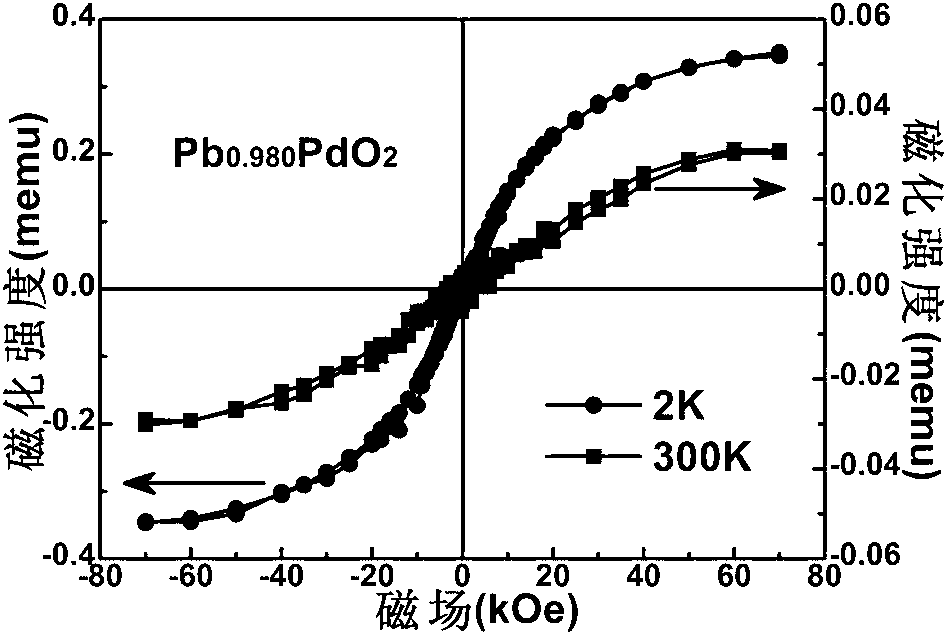

PbxPdO2 block material with room-temperature ferromagnetism, and preparation method thereof

A room temperature ferromagnetic, bulk material technology, applied in the field of PbxPdO2 bulk material and preparation, to achieve the effects of easy transportation and storage, low hazard, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] After passing the PbO powder, PdO powder and PVA powder through a 100 mesh sieve respectively, weigh the PbO powder, PdO powder and PVA powder according to the mass ratio of 1.82:1:0.04;

[0024] Mix and grind PbO powder and PdO powder until uniform, then add PVA powder and continue mixing and grinding until uniform;

[0025] A homogeneously mixed powder consisting of PbO powder, PdO powder, and PVA powder was put into a mold for preparing bulk materials, and then 100kg / cm 2 The pressure is kept under pressure for 15 minutes to obtain a block shaped blank;

[0026] Put the block blank into a heat treatment furnace and calcined in an oxygen atmosphere. The heating curve of the calcining is as follows: firstly, the temperature is raised to 150°C at a heating rate of 15°C / min, and then the temperature is raised to 150°C at a heating rate of 1°C / min. to 300°C and keep it warm for 1 hour, and finally raise the temperature to 680°C at a heating rate of 6°C / min and hold it fo...

Embodiment 2

[0029] After passing the PbO powder, PdO powder and PVA powder through a 100 mesh sieve respectively, weigh the PbO powder, PdO powder and PVA powder respectively according to the mass ratio of 1.78:1:0.04;

[0030] Mix and grind PbO powder and PdO powder until uniform, then add PVA powder and continue mixing and grinding until uniform;

[0031] A homogeneously mixed powder consisting of PbO powder, PdO powder, and PVA powder was put into a mold for preparing bulk materials, and then 100kg / cm 2 The pressure is kept under pressure for 15 minutes to obtain a block shaped blank;

[0032] Put the block blank into a heat treatment furnace and calcined in an oxygen atmosphere. The heating curve of the calcining is as follows: firstly, the temperature is raised to 150°C at a heating rate of 5°C / min, and then the temperature is raised to 150°C at a heating rate of 0.75°C / min. to 300°C and keep it warm for 1 hour, and finally raise the temperature to 700°C at a heating rate of 4°C / min...

Embodiment 3

[0035] After passing the PbO powder, PdO powder and PVA powder through a 100 mesh sieve respectively, weigh the PbO powder, PdO powder and PVA powder according to the mass ratio of 1.70:1:0.04;

[0036] Mix and grind PbO powder and PdO powder until uniform, then add PVA powder and continue mixing and grinding until uniform;

[0037] A homogeneously mixed powder consisting of PbO powder, PdO powder, and PVA powder was put into a mold for preparing bulk materials, and then 100kg / cm 2 The pressure is kept under pressure for 15 minutes to obtain a block shaped blank;

[0038] Put the block blank into the heat treatment furnace and calcined in the air atmosphere. The heating curve of the calcination is: firstly, the temperature is raised to 150°C at a heating rate of 1.5°C / min, and then the temperature is raised to 150°C at a heating rate of 0.5°C / min. to 300°C and keep it warm for 1 hour, and finally raise the temperature to 720°C at a heating rate of 2.85°C / min and keep it there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com