Machining technology for tube supports of non-allowance circular structure steel tubes and tube support structure

The invention relates to a processing technology and a technology for a pipe support, which is applied in the field of the processing technology and the structure of the pipe support of a circular structure steel pipe without a margin. Efficiency and welding quality, reducing production costs, and shortening the effect of construction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

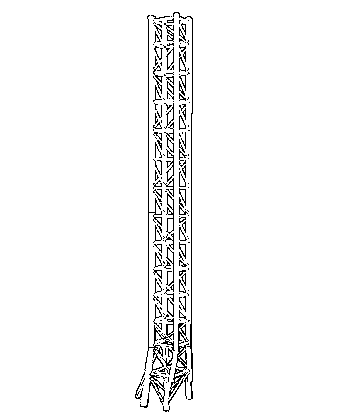

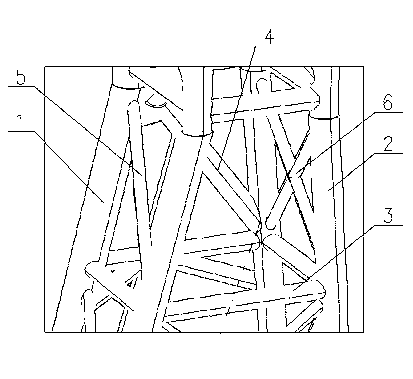

[0017] Such as figure 1 and figure 2 As shown, the steel pipe support with no allowance circular structure includes 3 main inclined pipes 1, 4 main straight pipes 2, main horizontal pipe 3, main crossing pipe 4, secondary inclined pipe 5 and secondary crossing pipe 6, secondary inclined pipe 5 is welded between the main inclined pipes 1, the secondary cross pipe 6 is welded between the main straight pipes 2, the main horizontal pipe 3 and the main cross pipe 4 are respectively welded between the main inclined pipe 1 and the main straight pipe 2, there is no margin The processing steps of circular structural steel pipe support are: Step A, understand the processing performance and parameters of the machine equipment. Due to the different machine sizes and models, their processing capabilities are also different, and the requirements for pipe diameter and related processing parameters are also different. Before designing the machine processing drawing, visit the tube processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com