An electrochromic device based on polythiophene and its derivatives and ionic liquid electrolyte and its application

An electrochromic device, ionic liquid technology, applied in instruments, nonlinear optics, optics, etc., can solve the problems of insufficient cycle life of the device, unstable electrochemical performance, flammable device electrolyte, etc. The effect of superior matching and long working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

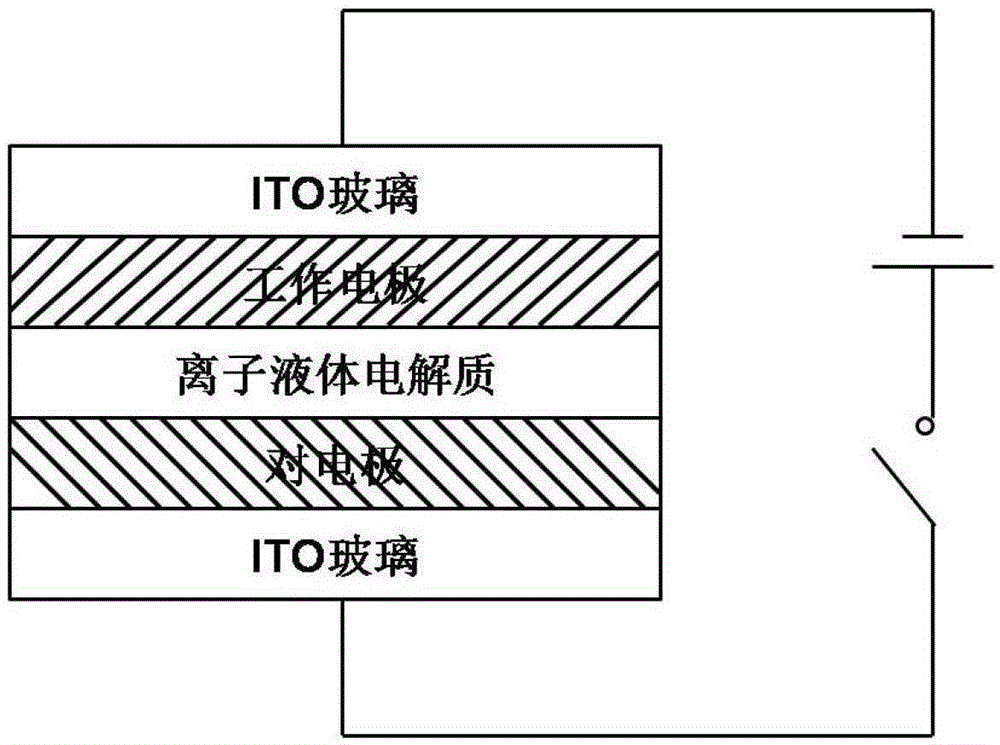

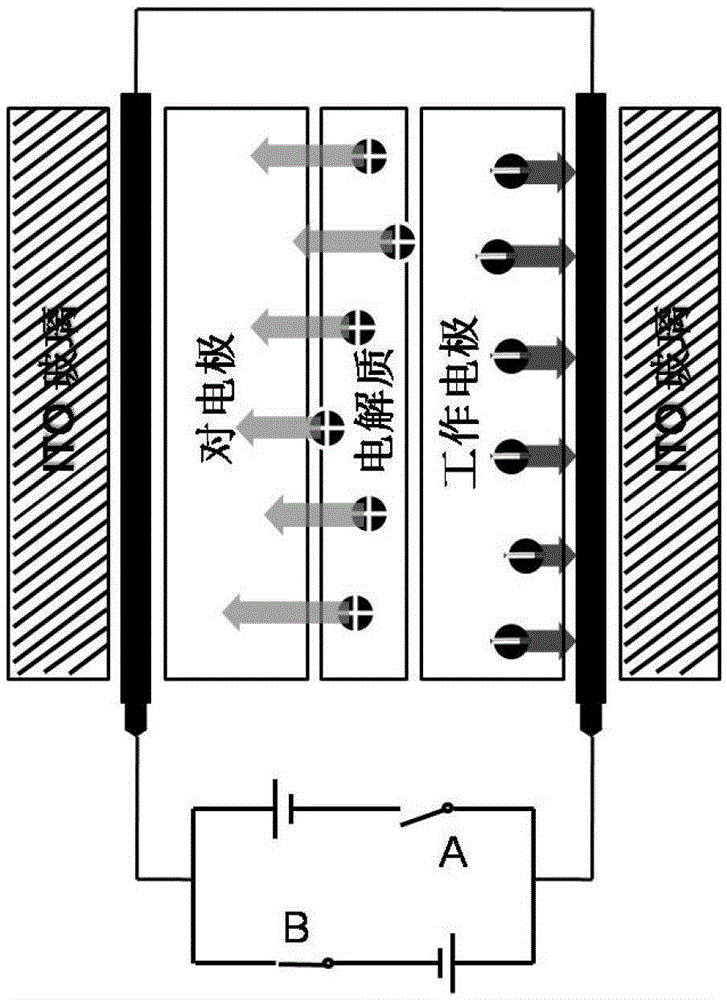

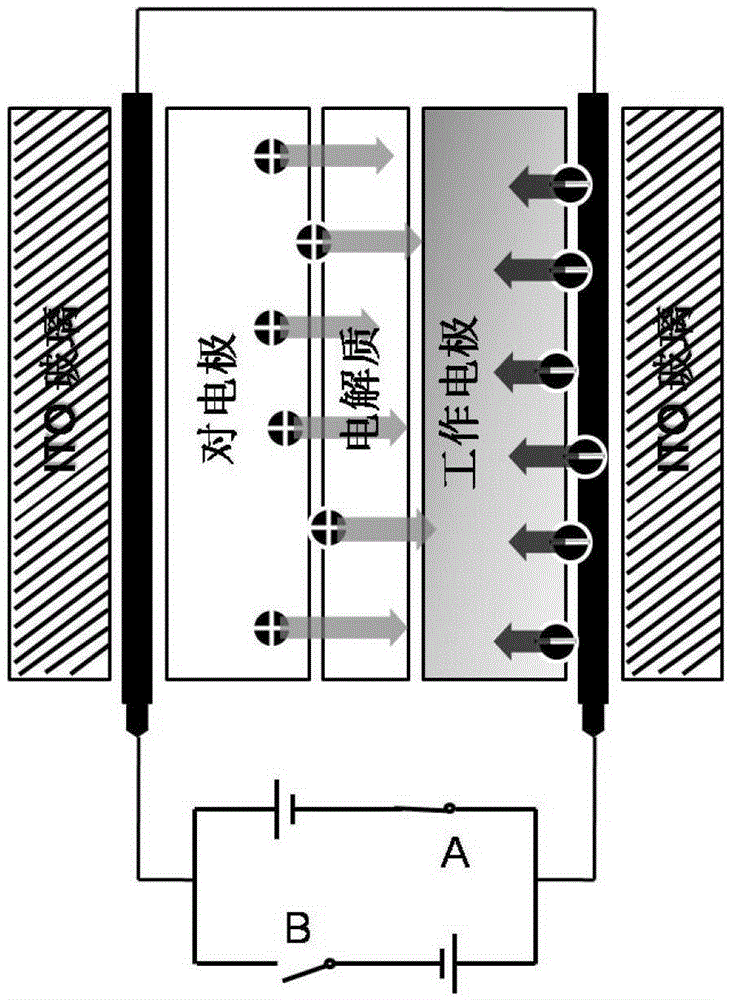

[0043] Example 1 Preparation of electrochromic device

[0044] The preparation process of the first electrode includes: according to the method reported in the literature (C. Kaneko, C. Xu, L. Liu, N. Dai, and M. Taya, Proc. of SPIE, vol. 5759, pp. 518, 2005), The acetonitrile solution of PProDOT-Me2 monomer is electroplated to deposit the polymer conductive film on the ITO glass immersed in the solution. The working electrode after film formation should be tested for coloring and fading in an electrochemical workstation.

[0045] The preparation process of the second electrode includes: according to the method reported in the literature (C. Kaneko, C. Xu, L. Liu, N. Dai, and M. Taya, Proc. of SPIE, vol. 5759, pp. 518, 2005), V 2 O 5 The sol is electroplated to deposit a conductive film on the ITO glass immersed in it. The counter electrode after film formation should be heat treated, the temperature is preferably in the range of 80-150°C, and the time is preferably in the range ...

Embodiment 2

[0048] Example 2 Comparison of performance between the electrochromic device of the present invention and other electrochromic devices

Embodiment 3

[0055] Example 3 Comparative experiment of electrolyte of electrochromic device

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com