Preparation method of high-temperature-resistant and corrosion-resistant fluorine-containing organic silicon/SiO2 nano-hybrided coatings

A silicone and corrosion-resistant technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems affecting the hydrophobicity and corrosion resistance of the coating, the hydrolysis rate is difficult to control, and the substrate is corrosive, so as to achieve the stability of the coating synthesis process , the effect of improving mechanical properties and improving hydrophobic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

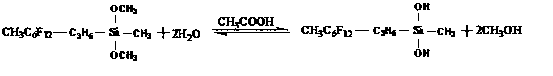

Method used

Image

Examples

Embodiment 1

[0030] Dissolve 0.07mol tetraethyl orthosilicate in 0.36mol absolute ethanol at room temperature, add dropwise 0.18mol distilled water and 0.0036mol acetic acid, react for 30min, then add 0.02mol dodecafluoroheptylpropylmethyldimethoxysilane in turn , 0.09mol methylphenyldimethoxysilane, reacted for 1h and then heated up to 50°C, condensed and refluxed for 10h to obtain colorless and transparent fluorine-containing silicone / SiO 2 The hybrid sol was sealed and left to stand after cooling to room temperature. The whole reaction process needs to be stirred.

[0031] After a period of time, the hybrid sol that has been sealed and stood still is coated on the substrate (requires pre-treatment such as sandpaper polishing) by brushing (the substrate is tin plate and LY12 aluminum alloy, of which LY12 aluminum alloy is used for heat resistance test , other tests are tinplate plate), after the solvent evaporates, it is cured at 120°C for 10h to obtain fluorine-containing silicone / SiO ...

Embodiment 2

[0033] Dissolve 0.1mol ethyl orthosilicate in 0.44mol absolute ethanol at room temperature, add 0.22mol distilled water and 0.0066mol acetic acid dropwise, react for 45min, then add 0.04mol dodecafluoroheptylpropylmethyldimethoxysilane in turn , 0.08mol methylphenyldimethoxysilane, reacted for 45 minutes and then heated to 70°C, condensed and refluxed for 6 hours to obtain colorless and transparent fluorine-containing silicone / SiO 2 The hybrid sol was sealed and left to stand after cooling to room temperature. The whole reaction process needs to be stirred.

[0034] After a period of time, the hybrid sol that has been sealed and stood still is coated on the substrate (requires pre-treatment such as sandpaper polishing) by brushing (the substrate is tin plate and LY12 aluminum alloy, of which LY12 aluminum alloy is used for heat resistance test , other tests are tinplate plate), after the solvent evaporates, it is cured at 120°C for 10h to obtain fluorine-containing silicone / S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com