Method for preparing ethylene by dehydrating ethanol

A technology for ethanol dehydration and ethylene, applied in chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, organic chemistry, etc., can solve problems such as poor catalyst stability, achieve good stability, improve carbon storage capacity, and prolong catalyst life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

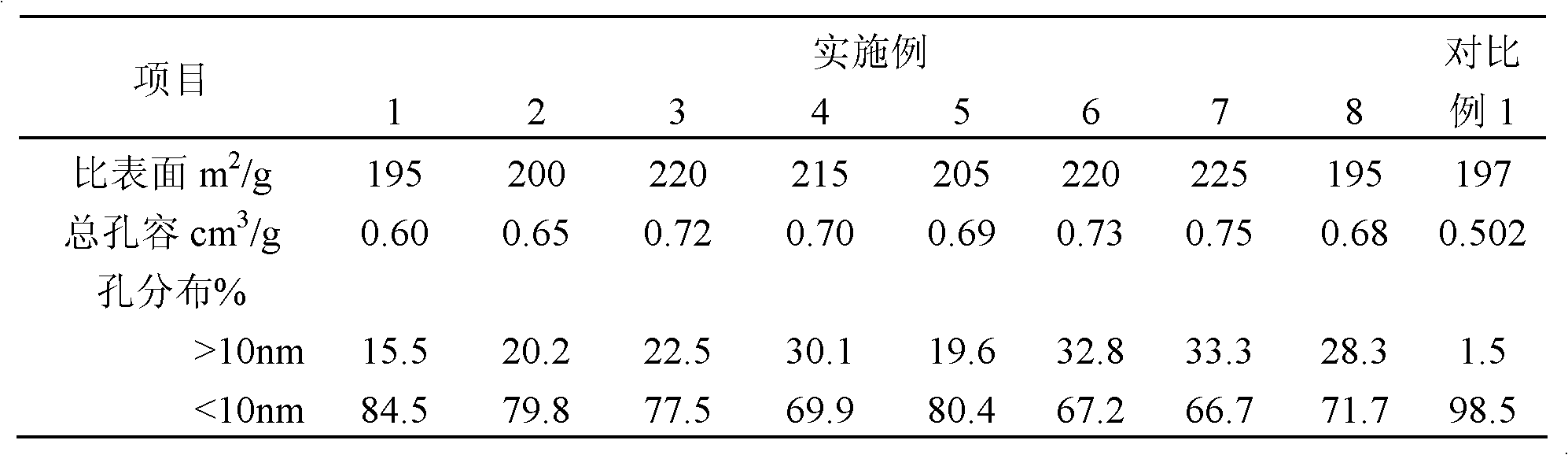

Embodiment 1

[0018] Weigh 250 grams of pseudo-boehmite, 30 grams of starch, and 12.5 grams of scallop powder, knead them in a kneader for 30 minutes, add 225 ml of 5% nitric acid solution, knead for another 20 minutes, then extrude into strips, and dry at 110°C for 10 hours , and then activated in a muffle furnace at 650° C. for 8 hours to obtain catalyst A. The physical properties of the catalysts are listed in Table 1.

Embodiment 2

[0020] Weigh 300 grams of aluminum hydroxide, 80 grams of polyethylene glycol, and 15 grams of squash powder, and knead them in a kneader for 30 minutes, add 185 milliliters of 5% nitric acid solution, and knead for another 15 minutes, then extrude into strips, and dry at 120 ° C for 10 minutes. Hours, and then activated in a muffle furnace at 600°C for 8 hours to obtain catalyst B. The physical properties of the catalysts are listed in Table 1.

Embodiment 3

[0022] Weigh 200 grams of boehmite, 100 grams of urea, and 15 grams of scallop powder, knead in a kneader for 30 minutes, add 250 ml of 5% nitric acid solution, knead for another 25 minutes, then extrude into strips, and dry at 110 ° C for 15 hours. Then place it in a muffle furnace at 500° C. for 6 hours to obtain catalyst C. The physical properties of the catalysts are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com