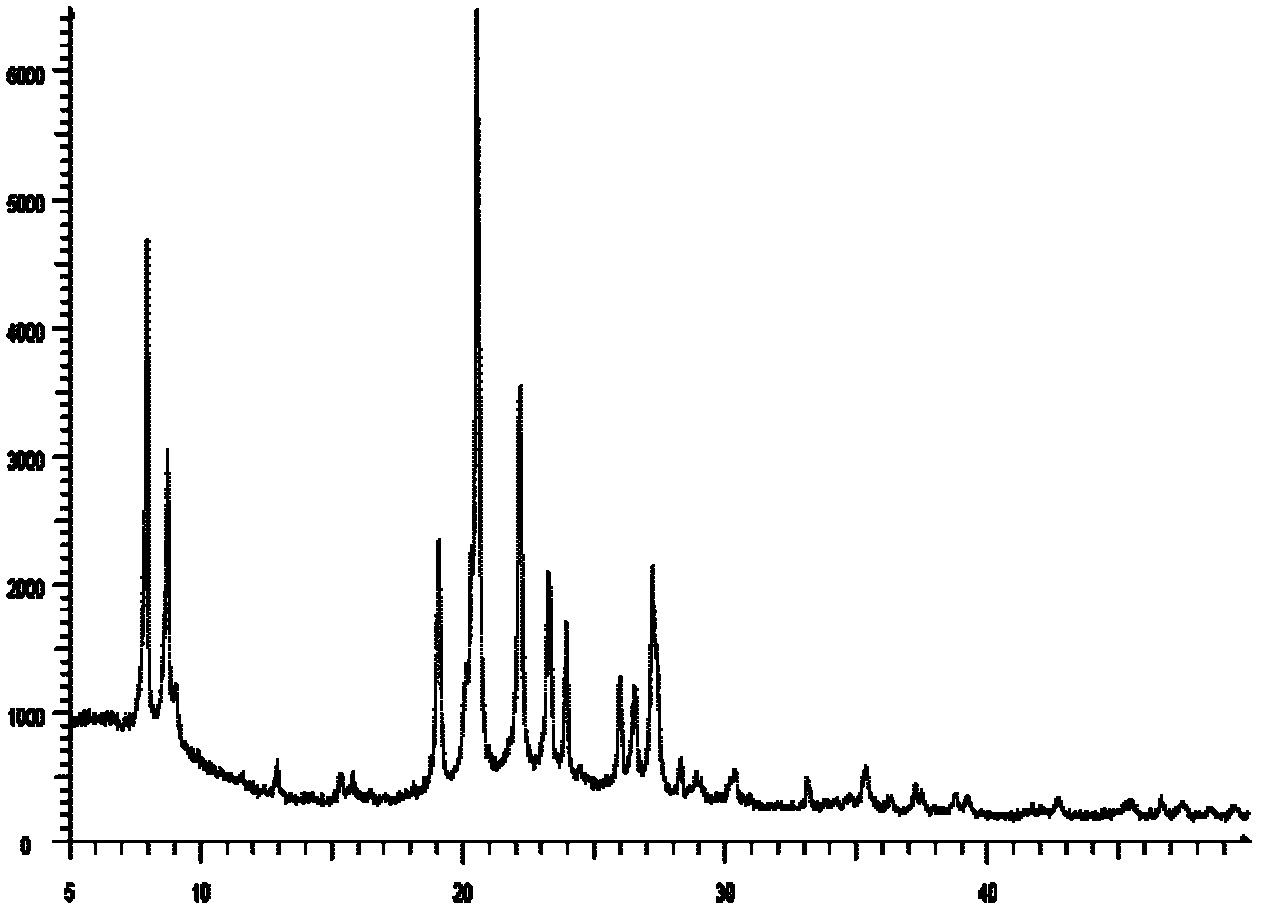

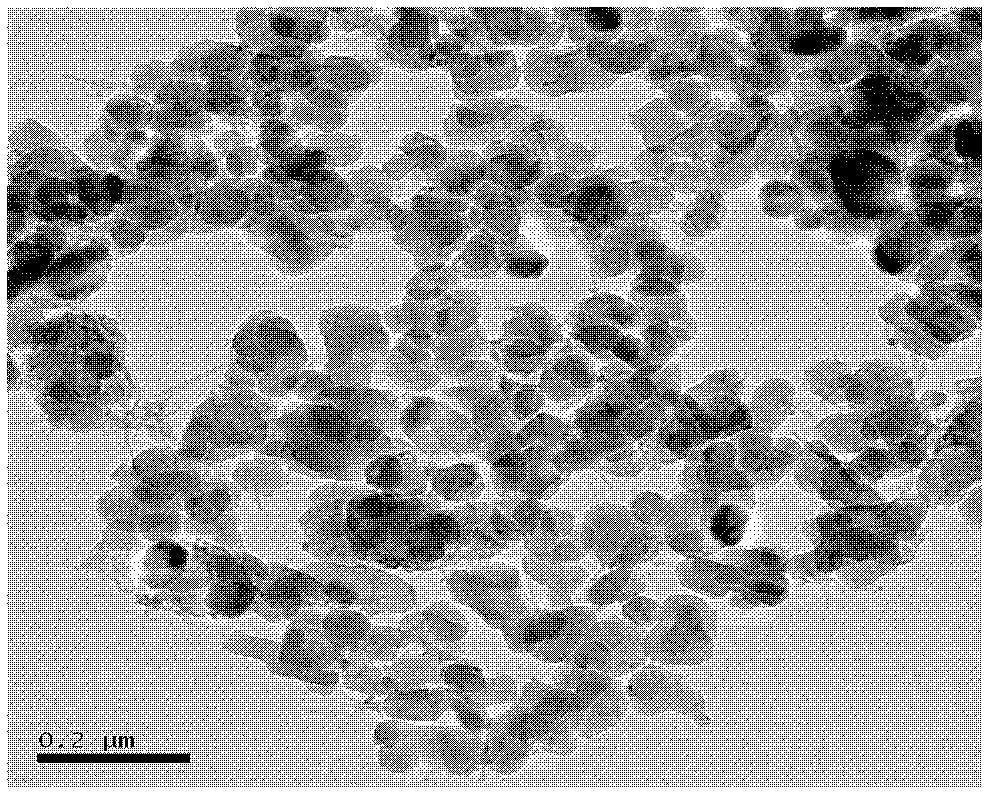

Preparation method of EUO structural nano silica-alumina molecular sieves

A technology of molecular sieve and nano-silicon, which is applied in the field of preparation of silicon-aluminum molecular sieve, can solve the problems of crystal phase impurity, low yield, large particle size of EUO structure molecular sieve, etc., and achieve short synthesis time, good repeatability and excellent isomerism The effects of chemical activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weighed 1.41g of sodium metaaluminate (chemically pure, with mass content of aluminum oxide ≥ 41%, mass content of sodium oxide ≥ 31%, the same below) and dissolved in 30 g of deionized water to obtain solution A. In addition, 50g of silica sol (ammonium type, produced by Foshan Lianjie Silicon Material Co., Ltd., with a mass content of silicon dioxide of 40%, the same below) was dissolved in 20g of deionized water to obtain solution B, and solution B was slowly added dropwise under stirring Add 6g of hexamethylammonium bromide to the solution A to react into a gel, add 6g of hexamethylammonium bromide after the dropwise addition, stir vigorously for a period of time, then use an appropriate amount of sodium hydroxide (analytically pure, >96%) to adjust the pH value of the gel to 12 to control the molar composition of the gel. Ratio: SiO 2 / Al 2 o 3 =60,H 2 O / Al 2 o 3 =730,OH - / Al 2 o 3 =4.5, R / Al 2 o 3 =2.99, Na 2 O / Al 2 o 3 = 3.77, then add 6g of hexamet...

Embodiment 2~6

[0039] Molecular sieves were prepared according to the method of Example 1, the difference being that the initial gel silica-alumina ratio was different, and the amounts of raw materials and crystallization conditions used in each example were listed in Table 1.

[0040] Table 1

[0041]

Embodiment 7

[0043] (1) Preparation of template precursor N1

[0044] 180g of dibromohexane, 90g of trimethylamine (40%) and 180g of deionized water were mixed at room temperature, and fully stirred to obtain template precursor N1.

[0045] (2) Synthetic molecular sieve

[0046] Stir and dissolve quantitative sodium aluminate (A.R, alumina mass content > 41%, sodium oxide mass content 31%) and mineralizer in a certain amount of deionized water to obtain acid solution A, mix silica sol with a certain amount of deionized water Evenly obtain lye B, add solution B dropwise to solution A at room temperature ~ 80°C under stirring, then add the calculated amount of template agent, stir well to obtain the initial gel mixture, and move the mixture into a stainless steel crystallization kettle React at 180°C for 48 hours, and the reaction product is cooled, filtered, washed, and dried to obtain EUO structure nano-silicon-aluminum molecular sieve raw powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com