Method for preparing TiO2/SiO2 catalyst for exchanging and synthesizing diphenyl carbonate by dimethyl carbonate and phenol ester

A technology of diphenyl carbonate and catalyst, which is applied in the field of preparation of heterogeneous catalysts, can solve problems such as the decrease of catalyst reaction activity, and achieve the effects of short preparation time, simple preparation method and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take 9g urea and dissolve in 10.8g H 2 O, after stirring evenly, add acetylacetone and tetrabutyl titanate, and stir at room temperature for 3h. After adding tetraethyl orthosilicate, with HNO 3 Adjust the pH of the solution (the molar ratio of Ti / Si is 1:20, and the molar ratio of acetylacetone and tetrabutyl titanate is 3:5); after the gel is aged for 2 hours, the volatile components are evaporated at 50°C. Calcined at 600°C for 4h.

Embodiment 2

[0022] Carry out the transesterification reaction of dimethyl carbonate and phenol with the catalyst prepared in embodiment 1

[0023] (1) in the there-necked flask that is connected with air guide tube and thermometer, constant pressure dropping funnel and rectifying column, add the catalyst 1.0 gram of embodiment 1;

[0024] (2) under feeding nitrogen, add 15 grams of phenol;

[0025] (3) When heating to 180°C, start to add dimethyl carbonate (DMC) dropwise, and the total amount of DMC added is 13.5ml. React 9.0 hours, constantly steam the mixed fraction of methyl alcohol and dimethyl carbonate by the rectifying column in the reaction process;

[0026] (4) The mixed fraction and the reaction solution containing the main product methyl phenyl carbonate and diphenyl carbonate are all analyzed by Shimadzu GC-14B gas chromatograph, quantified by calibration and normalization method, and record: the transformation rate of phenol is 38.3%, the yields of methyl phenyl carbonate a...

Embodiment 3

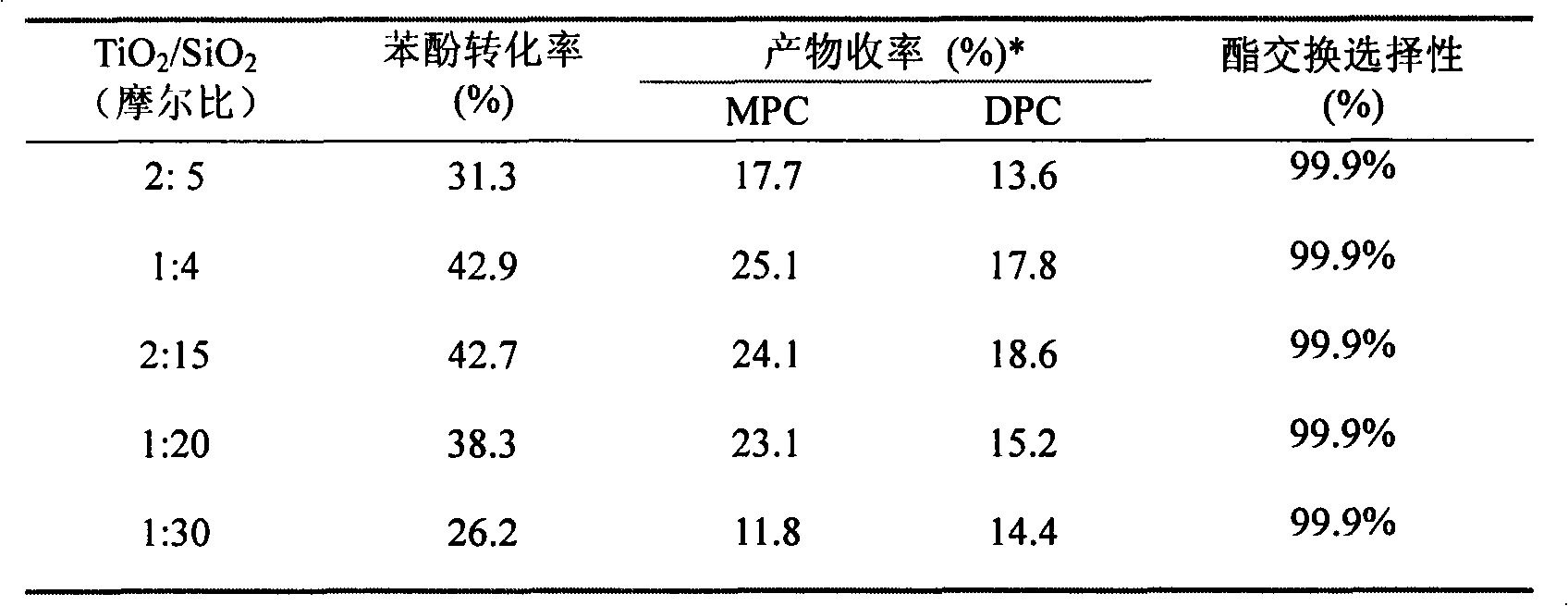

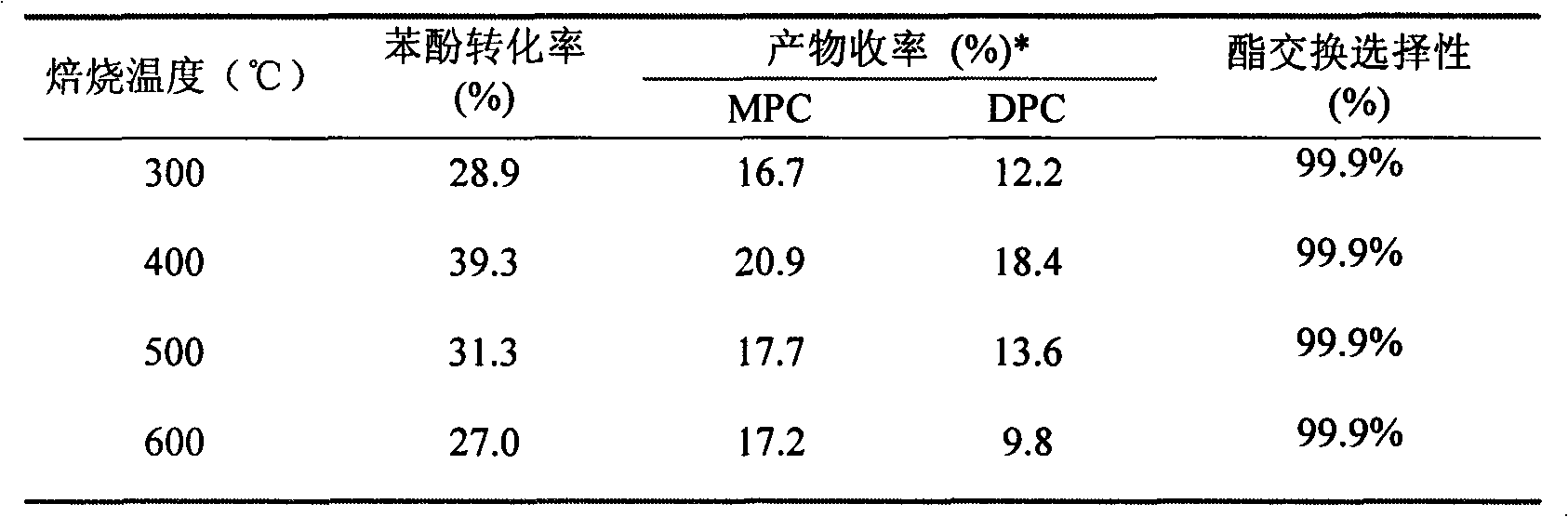

[0028] The preparation step of catalyst is the same as embodiment 1, but changes TiO 2 with SiO 2 The molar ratio is shown in Table 2. Carry out the transesterification reaction of dimethyl carbonate and phenol with the prepared catalyst, the reaction conditions are the same as in Example 2, and the activity results are shown in Table 1.

[0029] Table 1 Different TiO 2 / SiO 2 The effect of molar ratio on catalyst activity

[0030]

[0031] *MPC-methylphenyl carbonate, DPC-diphenyl carbonate

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com