Method for extracting unsaturated fatty acid from bischofia polycarpa fruits

A technology of unsaturated fatty acids and Chongyang wood, which is applied in the direction of fat production, fat oil/fat production, etc., can solve the problems of low oil yield, unsuitable extraction of Chongyang wood unsaturated fatty acids, and complicated supercritical process, so as to improve the extraction efficiency, shortening the leaching time, shortening the effect of extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1, the method for extracting unsaturated fatty acid from the fruit of Chrysanthemum chrysalis, carries out the following steps successively:

[0017] 1) Dry the collected fruit of Chongyang tree at low temperature (50°C) to constant weight (when weighed on a ten-thousandth balance, the weight remains unchanged after 24 hours), and then crushed until it can pass through a 60-mesh sieve. Obtain the crushed Chongyang tree fruit;

[0018] 2) According to the solid-liquid ratio of 1g: 7ml, weigh 10g of crushed fruit of Chongyang tree and add 70ml of n-hexane as a solvent; ultrasonically extract for 1h at an ultrasonic power of 300w and an extraction temperature of 25°C (ultrasonic is limited by Kunshan Instruments) The CNC ultrasonic cleaner produced by the company, the model is KQ-500DE, the same below); the extract and residue are obtained separately;

[0019] 3) Wash the residue with n-hexane for 3 times, the amount of n-hexane used for each washing is 4 ml; v...

Embodiment 2

[0022] Embodiment 2, fatty acid methyl esterification in the fruit

[0023] Accurately measure 200 μl of the fruit oil obtained in Example 1 into a 10ml volumetric flask, then add 1ml of n-hexane and diethyl ether (V:V=2:1) mixed solution, shake gently for 2min, and make the oil (Chongyang tree fruit oil) completely dissolved. Then add 1ml of 0.5mol / L sodium hydroxide-methanol solution, let stand at room temperature (20~25°C) for 5-10min, add distilled water to make up to 10ml, oscillate and shake well, and after mixing, sonicate for 2min under the ultrasonic instrument (The power is 300W, the temperature is 25°C), and finally the mixed solution is transferred to a 10ml centrifuge tube and centrifuged at 4000rpm for 2min. A total of 500 μl of methylated fatty acid was obtained after dehydration of the upper layer solution. The methylated fatty acid was subjected to GC-MS analysis.

Embodiment 3

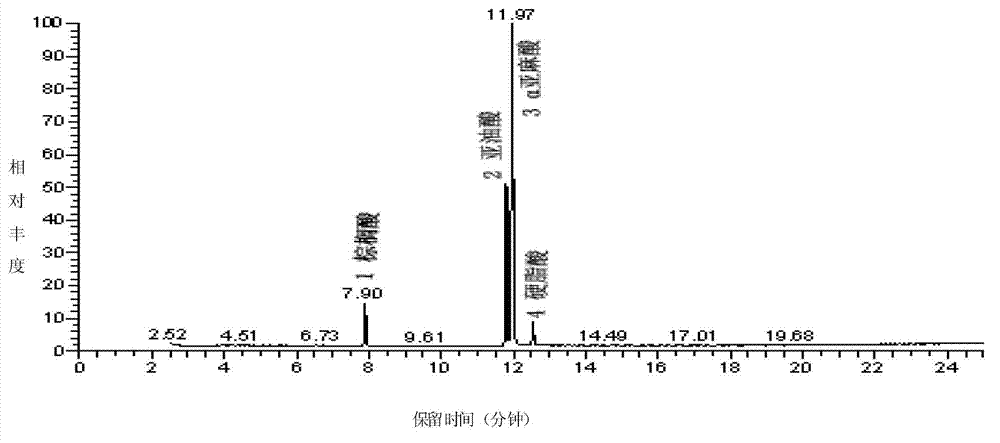

[0024] Example 3, using GC-MS (instrument is: Thermo Scientific gas chromatography, gas phase model is TRACE GC ULTRA; mass spectrometer model is ISQ; automatic sampler model is AS TriPLUS) to analyze the composition of the fruit fatty acids of Chongyang tree.

[0025] Gas chromatography conditions: chromatographic column (model: TR-5MS: 30m×0.25mm×0.25μm), solvent is n-hexane, carrier gas is high-purity helium (99.999%), heating program: initial temperature of 190°C for 5 minutes, heating The speed was 3°C / min, the stop temperature was 250°C and kept for 5 minutes, the temperature of the injection port was 220°C, the injection volume was 1 μL, and the split injection was performed with a split ratio of 100:1.

[0026] Mass spectrometry conditions: EI ionization source. The transfer line temperature was 250°C, the ion source temperature was 200°C, and the scan range was 40-600 amu.

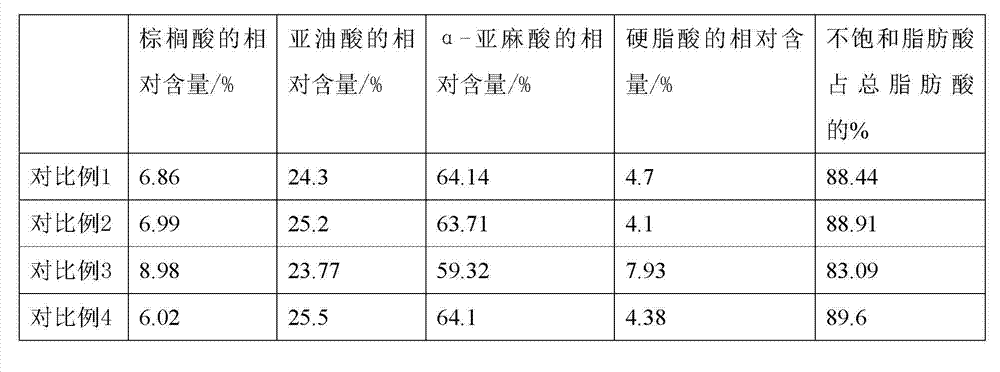

[0027] The composition of embodiment 2 gained is carried out GC-MS analysis, obtains the tota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com