Large-air-volume low-concentration plasma exhaust gas treatment device

A waste gas treatment device and plasma technology, applied in the direction of plasma, electrical components, separation methods, etc., can solve the problems of large electrode spacing, spark discharge, difficult stable discharge, etc., and achieve the effect of simple structure, convenient maintenance, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

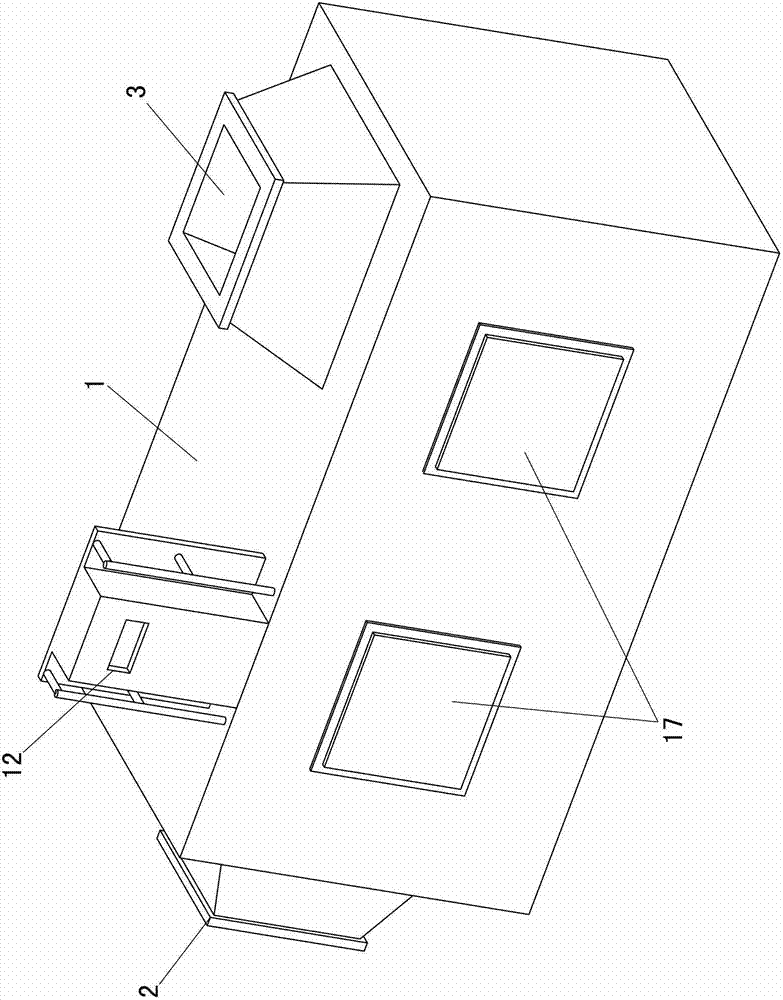

[0024] Such as figure 1 As shown, the high-volume low-concentration plasma waste gas treatment device of the present invention includes a plasma shell 1 . The plasma shell 1 is a cuboid box structure. Its left plate is processed with gradually expanding air inlet 2, its upper plate right portion is processed with tapering air outlet 3, and its front plate is processed with inspection hole 17.

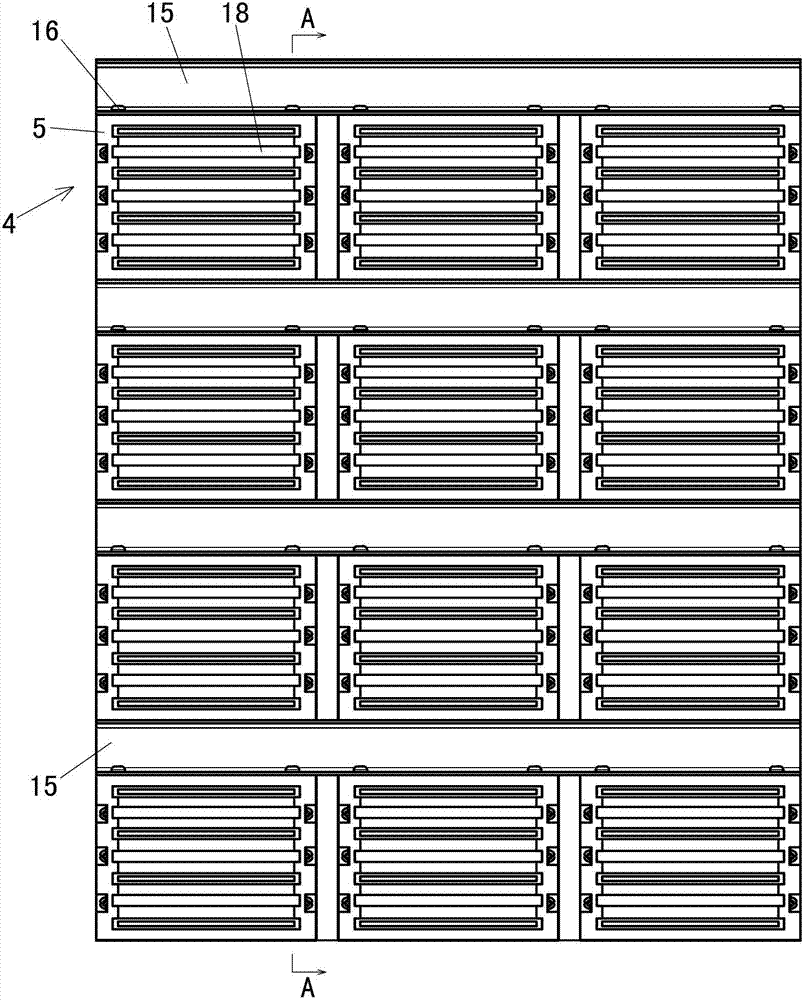

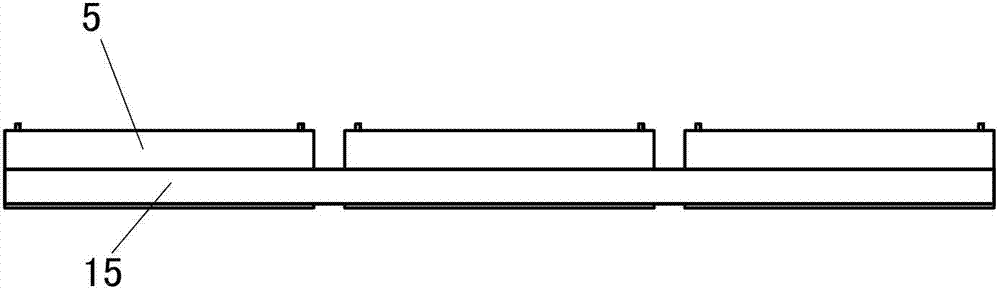

[0025] combine Figure 2 to Figure 4 As shown, 3×4 plasma generators 4 are installed in the same cross section of the inner chamber of the plasma housing 1 between the gas inlet 2 and the gas outlet 3 . That is, three plasma generators 4 are arranged horizontally, and four plasma generators 4 are arranged vertically. The plasma generators 4 are connected to each other along the outer edge and fill up the cross section. The plasma generator 4 is perpendicular to the gas inlet 2 of the plasma housing 1 . combine Figure 5 to Figure 7 As shown, a single plasma generator 4 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com