Substrate of organic electroluminescence device and production method thereof

An electroluminescent device and electroluminescent technology, which are applied in the fields of electro-solid devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as damage to organic layers, damage to the flatness of metal substrates, and influence on the luminous effect of OLED processes. To achieve the effect of simple preparation method, low roughness and good luminous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

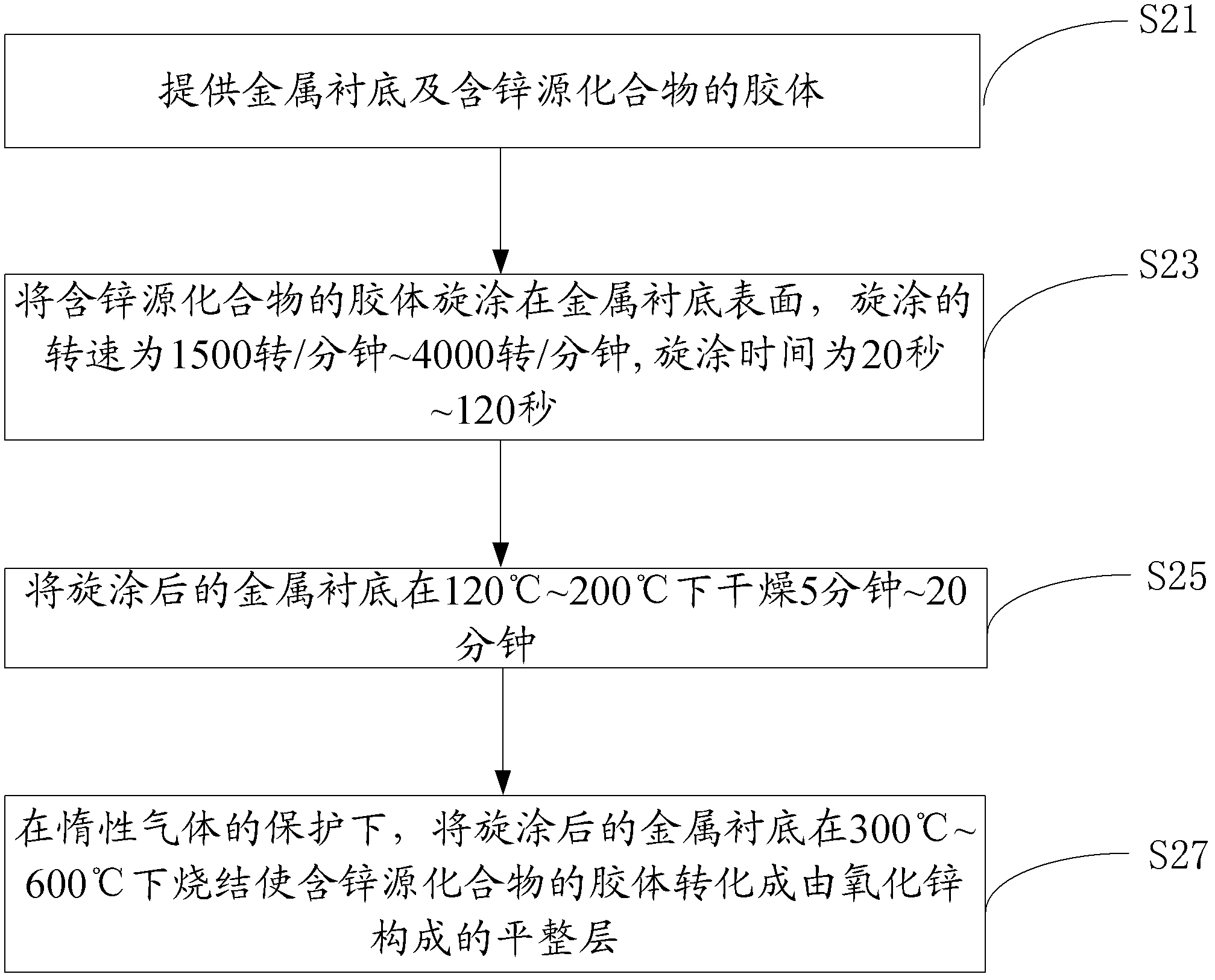

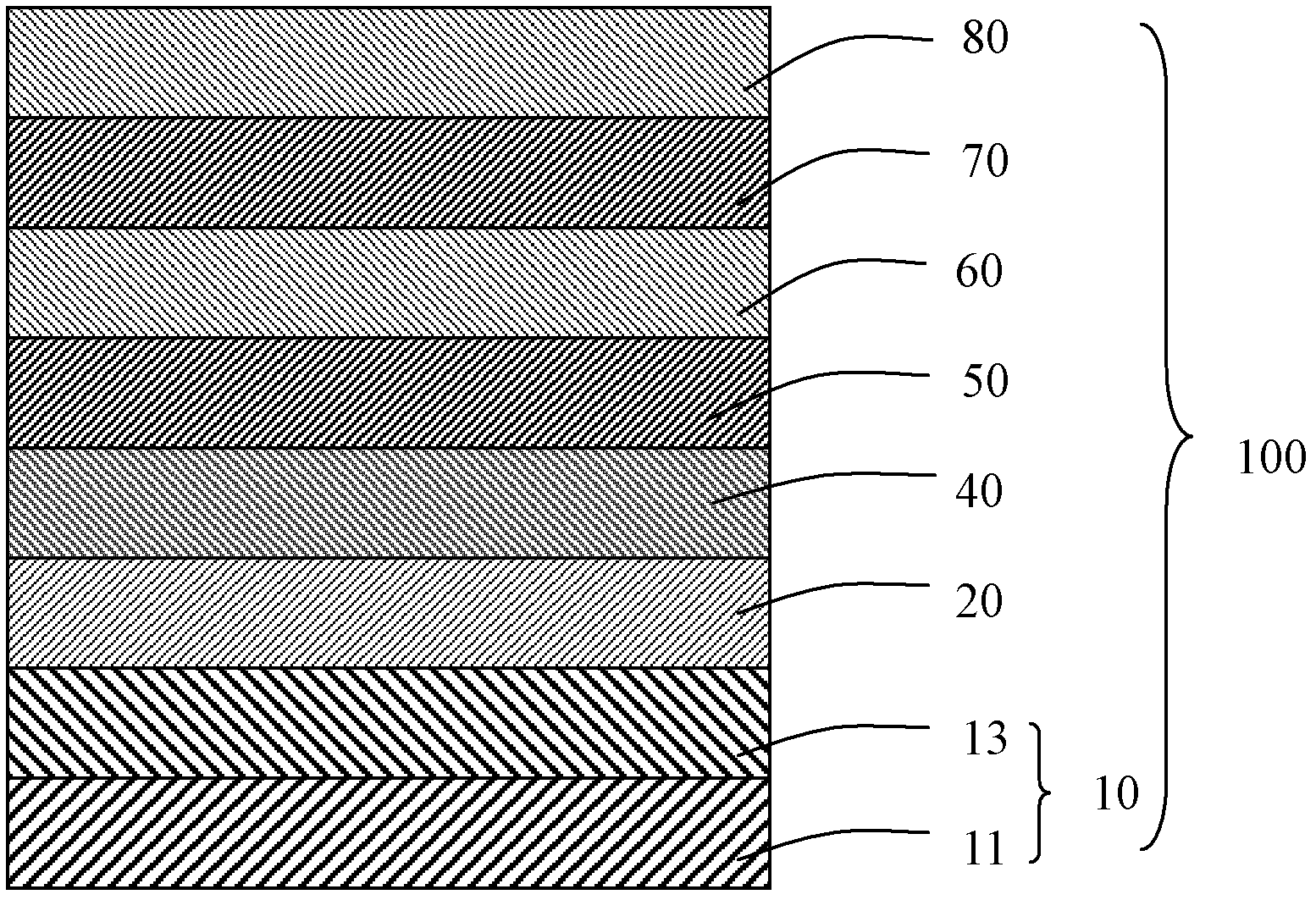

[0026] see figure 1 , the preparation method of the substrate of the organic electroluminescence device of an embodiment, comprises the following steps:

[0027] Step S21 , providing a colloid of a metal substrate and a zinc-containing source compound.

[0028] The preparation process of the colloid containing the zinc source compound is as follows: the zinc source compound is mixed with a solvent and a stabilizer and heated to reflux for 2 hours to form a zinc source compound colloid, and the concentration of zinc ions in the zinc source compound colloid is 0.2 mol / L~2mol / L. In this embodiment, the zinc source compound, the solvent and the stabilizer are mixed and stirred, heated to 60° C. and refluxed for 2 hours until the solution forms a uniform and transparent sol.

[0029] In this embodiment, the zinc source compound is zinc acetate, zinc selenite or zinc nitrate. The solvent is ethanol or ethylene glycol methyl ether. Stabilizer is ethanolamine stabilizer, such as e...

Embodiment 1

[0041] Add zinc acetate and triethanolamine to ethylene glycol methyl ether so that the concentration of zinc ions is 1mol / L, and the molar ratio of zinc ions to triethanolamine is 1:1, and then heat and reflux at 60°C for 2 hours until a solution is formed Uniform and transparent sol.

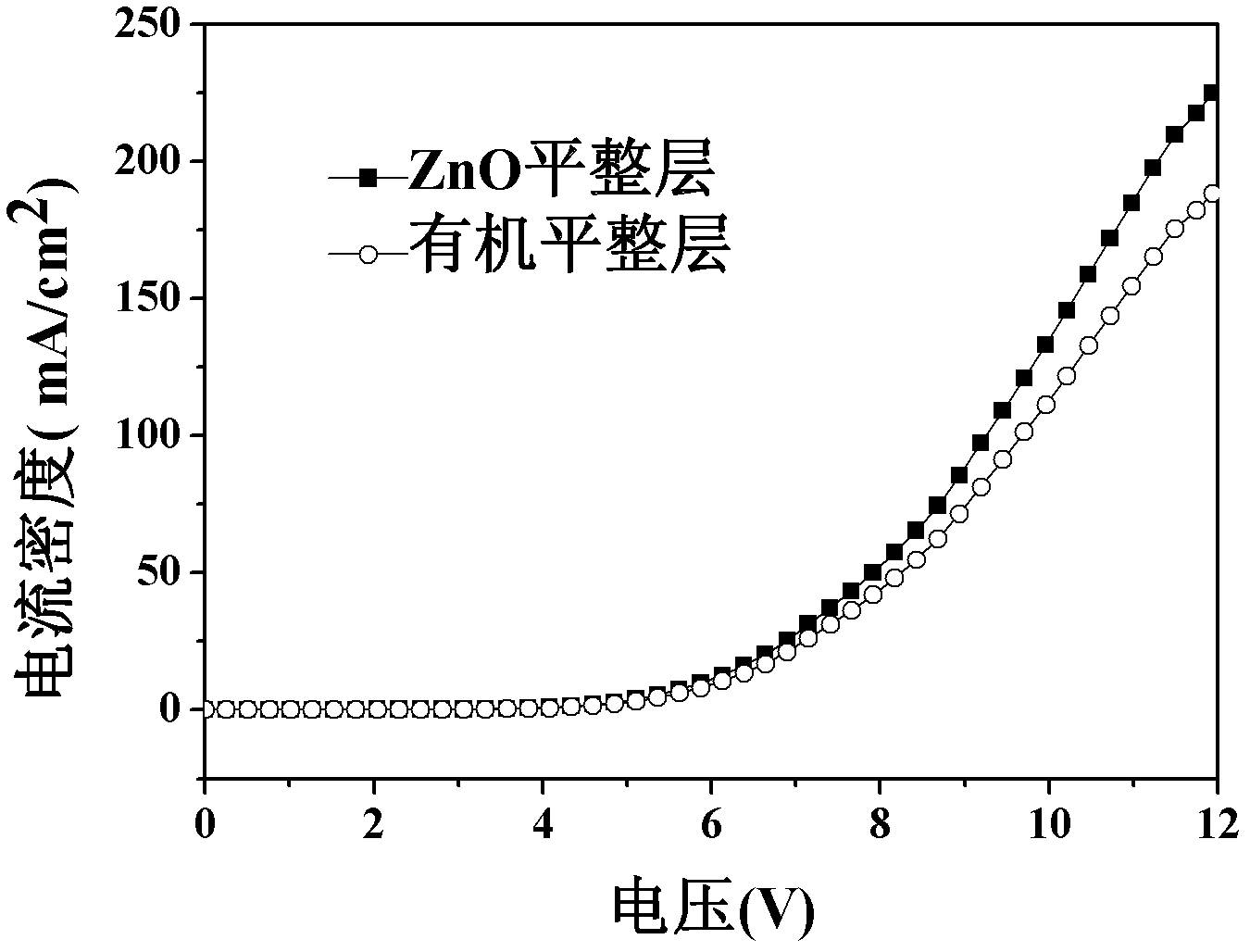

[0042] Take the stainless steel sheet, clean it after polishing, then drop the prepared zinc oxide colloid on the surface of the stainless steel sheet, and distribute the colloid evenly on the surface of the sheet by spin coating. During the spin-coating process, the spinning speed of the spinner was 2500 rpm, and the spin-coating time was 40 seconds. Dry the spin-coated sheet at 150°C for 10 minutes, and then spin-coat the colloid on the surface again. After the spin-coating is completed, dry it again. Repeat the spin-coating process for 5 times to obtain a smooth layer with a thickness of 1 μm. The stainless steel sheet prepared above is heated up to 500° C. under the protection of N2 and sin...

Embodiment 2

[0045] Add zinc nitrate and diethanolamine to ethanol to dissolve, so that the concentration of zinc ions is 0.2mol / L, and the molar ratio of zinc ions to diethanolamine is 1:0.5, and then heat and reflux at 60°C for 2 hours until the solution forms a uniform Transparent sol.

[0046] Take the stainless steel sheet, clean it after polishing, then drop the prepared zinc oxide colloid on the surface of the stainless steel sheet, and distribute the colloid evenly on the surface of the sheet by spin coating. During the spin-coating process, the spinning speed of the spinner was 1500 rpm, and the spin-coating time was 20 seconds. Dry the spin-coated sheet at 120°C for 5 minutes, and then spin-coat the colloid on the surface again. After the spin-coating is completed, dry it again. Repeat the spin-coating for 3 times, and finally obtain a smooth layer with a thickness of 0.2 μm. The stainless steel sheet prepared above is heated up to 300° C. under the protection of N2 and sintered...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com