Waterproof soft cable

A flexible cable and cable technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of decreased shielding performance of outer conductors, loss of transmission function of cables, damage to the whole set of cabinet equipment, etc., and achieves outstanding resistance to water trees and resistance. Corona performance, low thermal expansion coefficient, effect of stabilizing anti-electric pulse intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

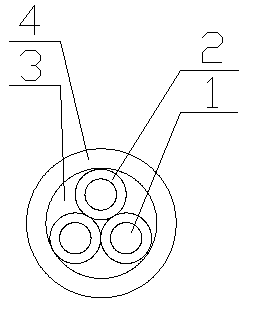

[0017] like figure 1 As shown, a waterproof flexible cable according to the present invention includes a cable core, which is characterized in that the cable core is formed by twisting three insulated wire cores; the inner space of the cable core is provided with a filling layer 3 made of filling, The outermost layer of the cable is extruded with a polyurethane elastomer outer sheath 4; the insulated wire core is composed of a copper conductor 1 and an outer insulating layer 2 wrapped around the conductor 1 in turn.

[0018] The present invention provides an idea and implementation method of a waterproof flexible cable. There are many specific application methods. The above description is only a preferred embodiment of the present invention. Under the premise of the principle of the invention, some improvements can also be made, and these improvements should also be regarded as the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com