Method for preparing erosion resistive and high-temperature abradable seal coating based on hot spraying

A sealing coating, erosion-resistant technology, applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve the problem of unable to meet the requirements of engine use, to eliminate the phase change affecting the life or performance of the coating Even failure, superior erosion resistance, significant erosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

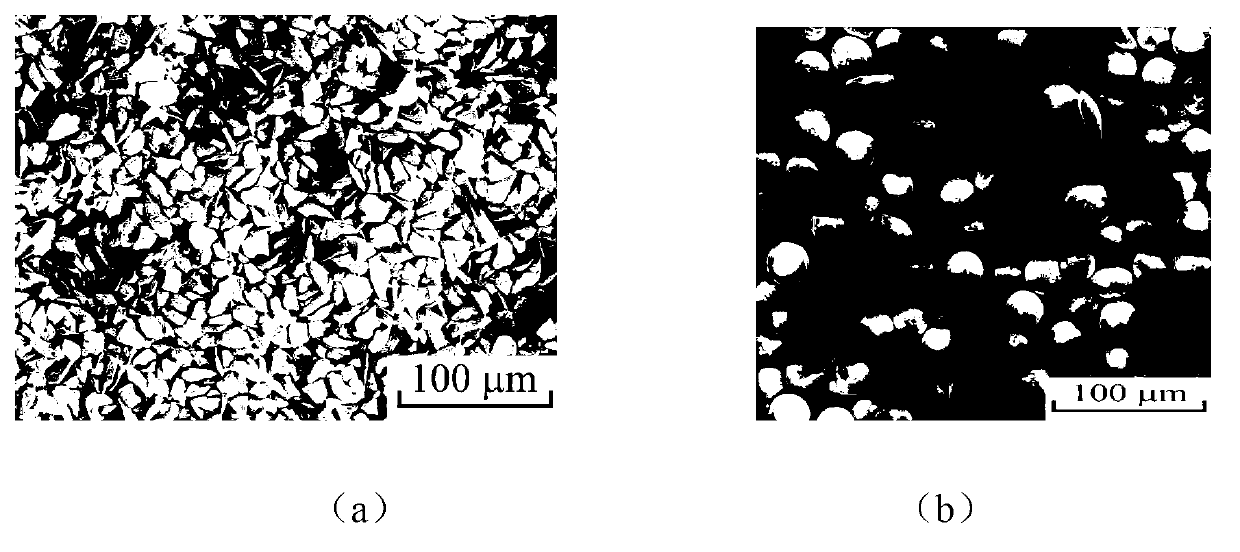

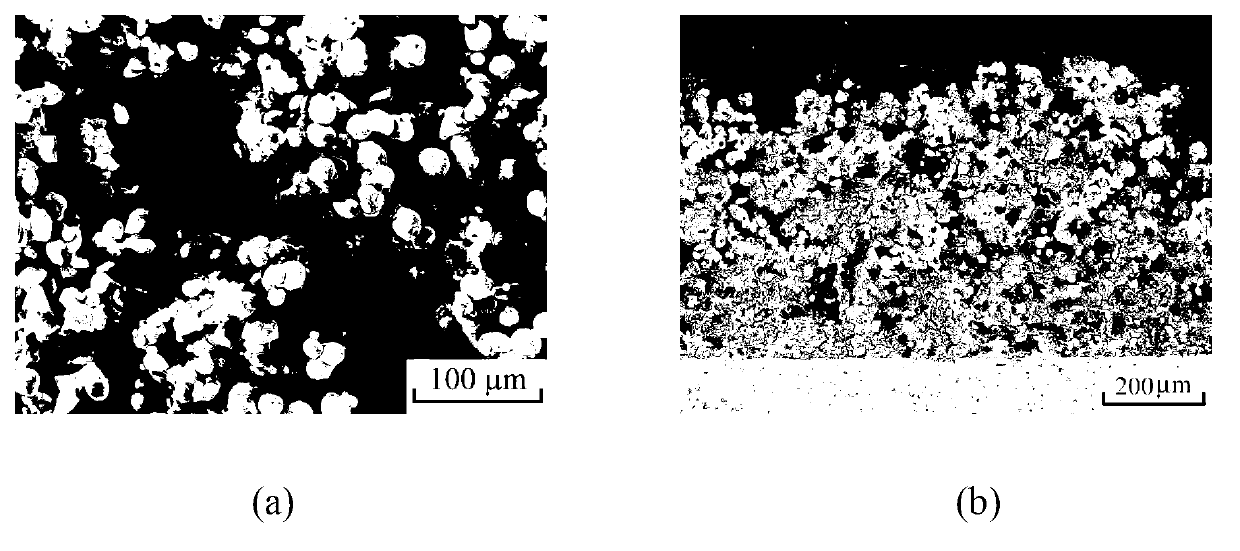

[0043] Al by flame spraying 2 o 3 Take powder as an example, part of the powder is hollow, and the particle size of the powder is 40~50μm, such as figure 1 shown. The flame gun is operated by the manipulator, and the speed of the gun is 30mm / s. Spraying uses oxygen for powder feeding, the flow rate of acetylene is 300L / h, the spraying distance is 20mm, the flame is a micro-oxidizing flame, and the flow rate of compressed air is 1500L / h. Will Al 2 o 3 The substrate sheet (compressed and sintered by spraying powder) was preheated to 1200°C for spraying, and the temperature in front of the substrate was monitored with an infrared thermometer (RAYRPM30L3U, Raytek, USA). The obtained surface and cross-sectional morphology are as figure 2 As shown, the formation of α-Al 2 o 3 This stable phase structure.

Embodiment 2

[0045] Al by flame spraying 2 o 3 Take powder as an example, part of the powder is hollow, and the particle size of the powder is 40~50μm, such as figure 1 shown. The flame gun is operated by the manipulator, and the speed of the gun is 30mm / s. Spraying uses oxygen for powder feeding, acetylene flow rate is 200L / h, 300L / h, 400L / h respectively, spraying distance is 40mm, flame is micro-oxidation flame, and compressed air flow rate is 1500L / h. The cross-sectional shape is as image 3 shown. It can be seen from the figure that with the increase of the acetylene flow rate, the open pores of the coating gradually decrease, and the closed pores that meet the requirements increase, and with the increase of the flow rate, the size of the closed pores decreases. It can be seen that by adjusting the flow rate of acetylene, a sealing coating with good performance required by the required porosity can be obtained.

Embodiment 3

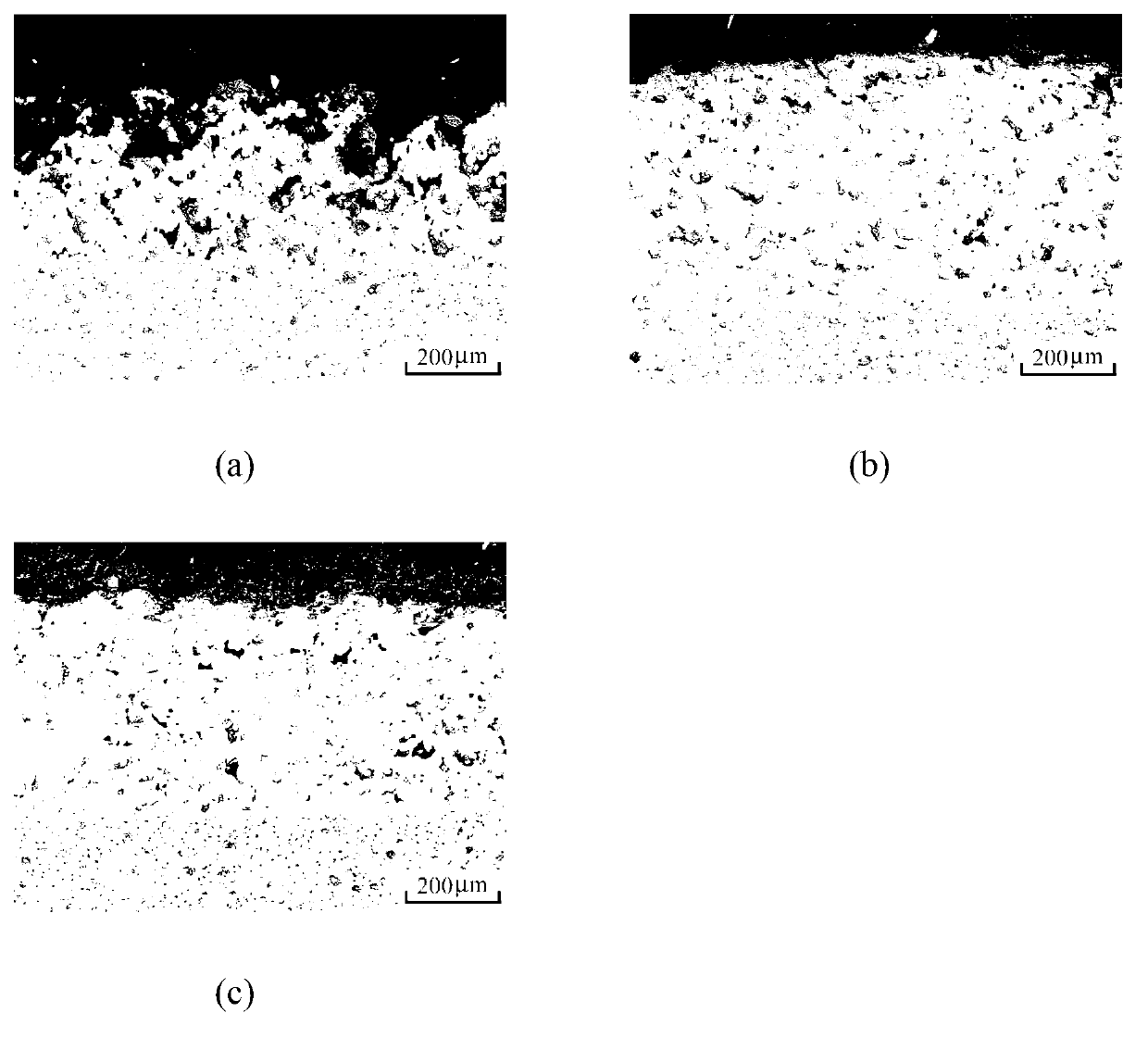

[0047] Al by flame spraying 2 o 3 Take powder as an example, part of the powder is hollow, and the particle size of the powder is 40~50μm, such as figure 1 shown. The flame gun is operated by the manipulator, and the speed of the gun is 30mm / s. Spraying uses oxygen for powder feeding, the acetylene flow rate is 400L / h, the spraying distance is 20mm, 30mm, 40mm, 60mm respectively, the flame is a micro-oxidation flame, and the compressed air flow rate is 1500L / h. The obtained surface morphology and cross-sectional morphology are as follows Figure 4 shown. Figure 4 (g) with Figure 4 The coating particles shown in (h) are completely melted, the coating has low porosity and is too dense, which does not meet the actual requirements of the sealing coating. It can be seen from the figure that the sealing coatings with different surface morphology and internal porosity can be obtained by adjusting the spraying distance. If the deposition surface temperature is controlled abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com