Machining method for manufacturing regular microtexture on surface of metal matrix or coating

A metal matrix and processing method technology, applied in the field of regular micro-textured surface processing, can solve the problems of workpiece surface accuracy, high size requirements, difficult mold preparation, affecting the overall efficiency of texture processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

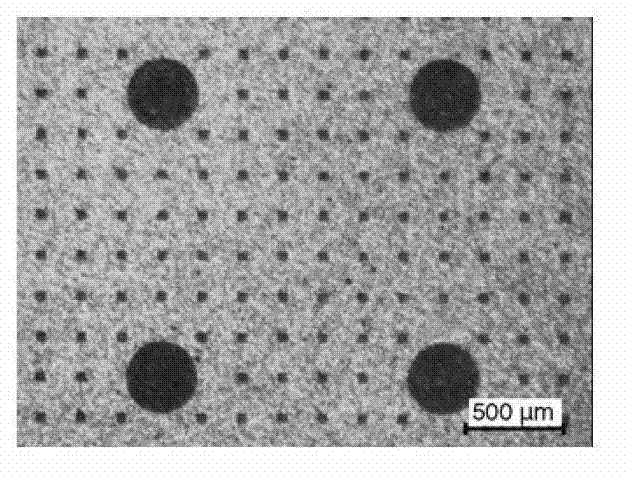

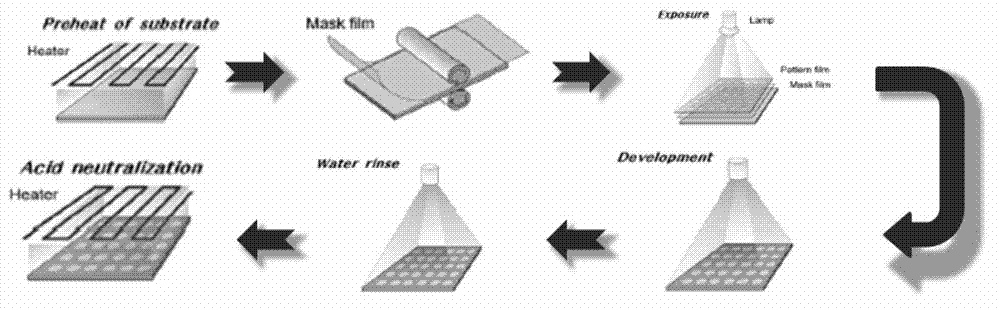

[0051] The invention is a processing method for processing regular micro-textures on the surface of metal substrates or coatings. The method combines laser processing technology and micro-abrasive jet processing technology, and uses metal sheets with different shapes and scales as masks. The surface of the substrate or coating is prepared with a pit-shaped micro-texture with different densities, Figure 5 It is a schematic diagram of the processing process, which mainly includes two steps of mask preparation and texture processing:

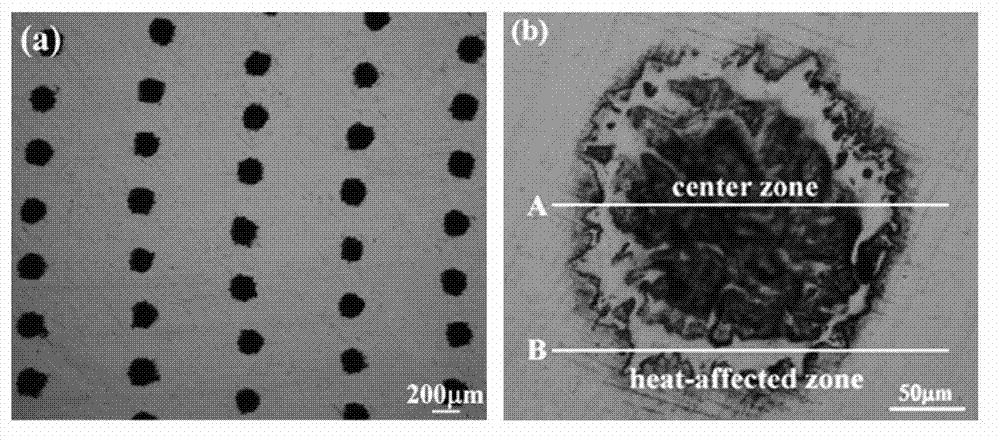

[0052] Step 1: Mask preparation: process a 304 stainless steel plate with a thickness of 150 μm, polish the surface of the plate, and clean it with chemical reagents. Circular textures with different diameters and spacings are designed and processed by a pulsed Nd:YAG laser processing system laser with a laser wavelength of 1064nm, an average power of 10W, a pulse width range of 5-25ns, and a pulse frequency of 10kHz. Figure 6 , Figure 7 This ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com