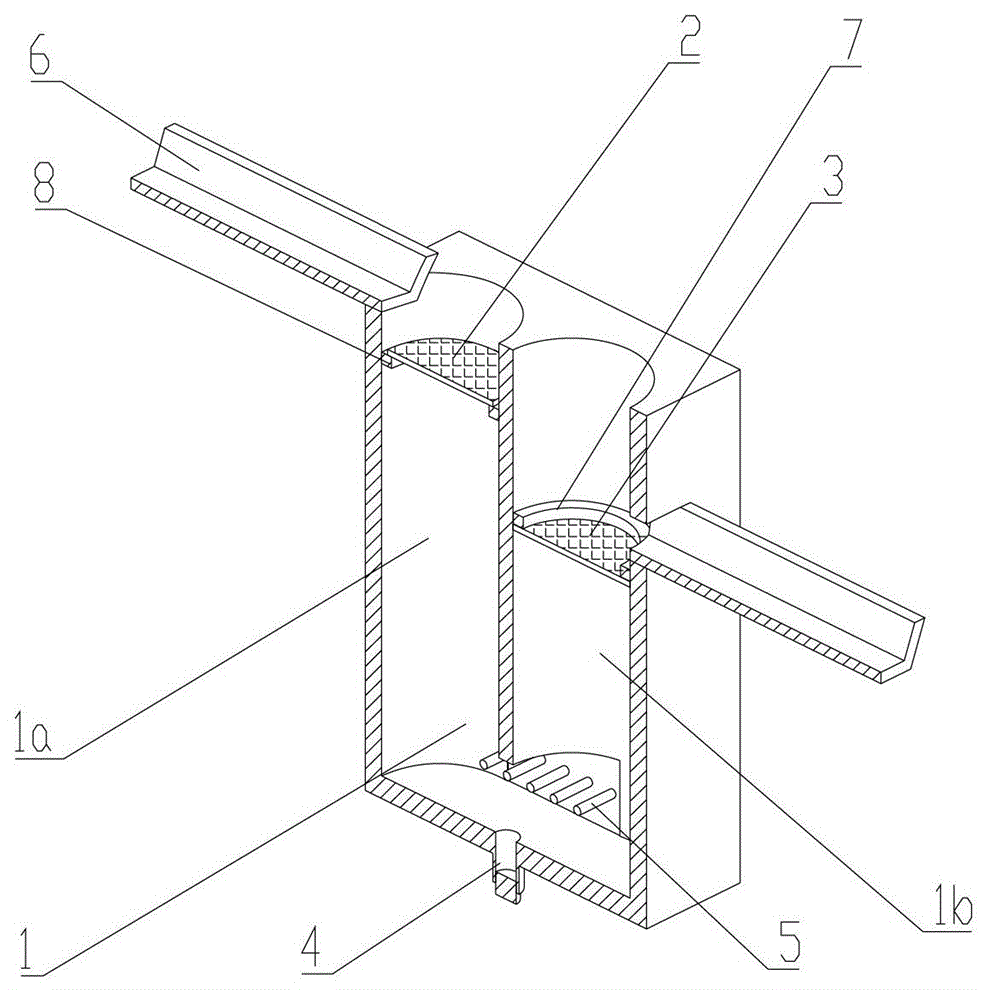

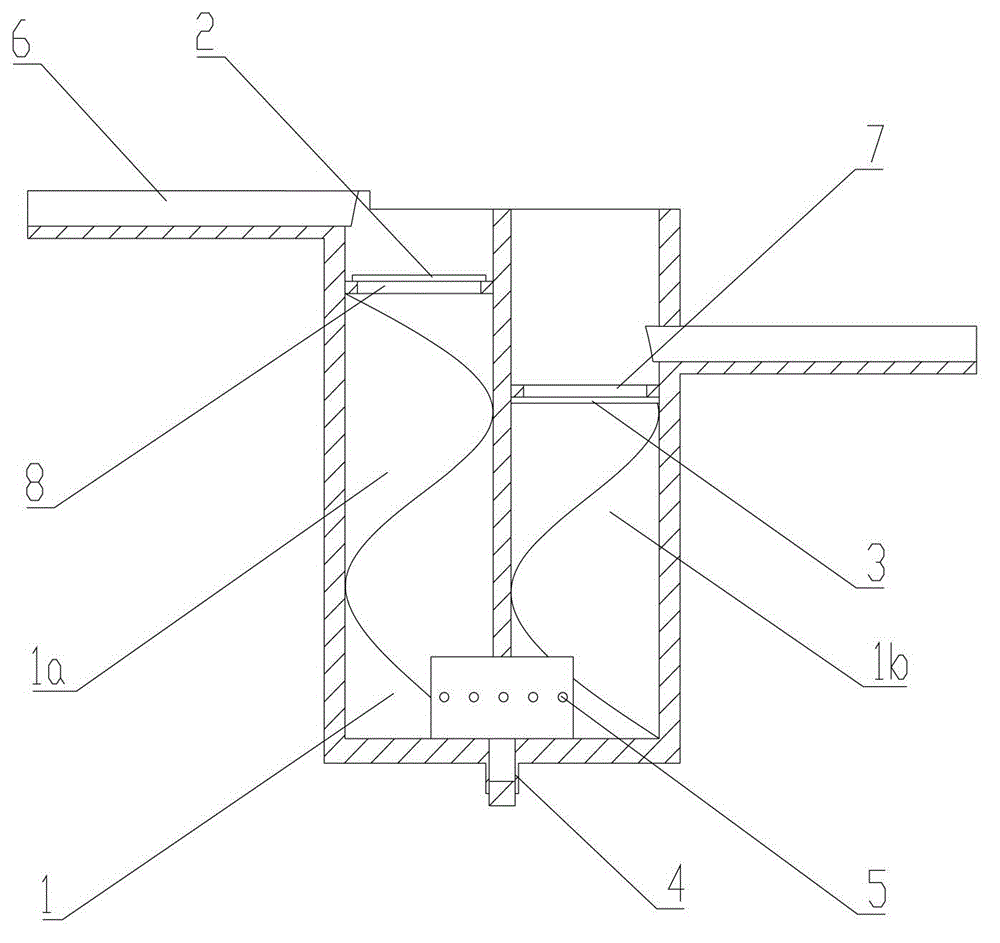

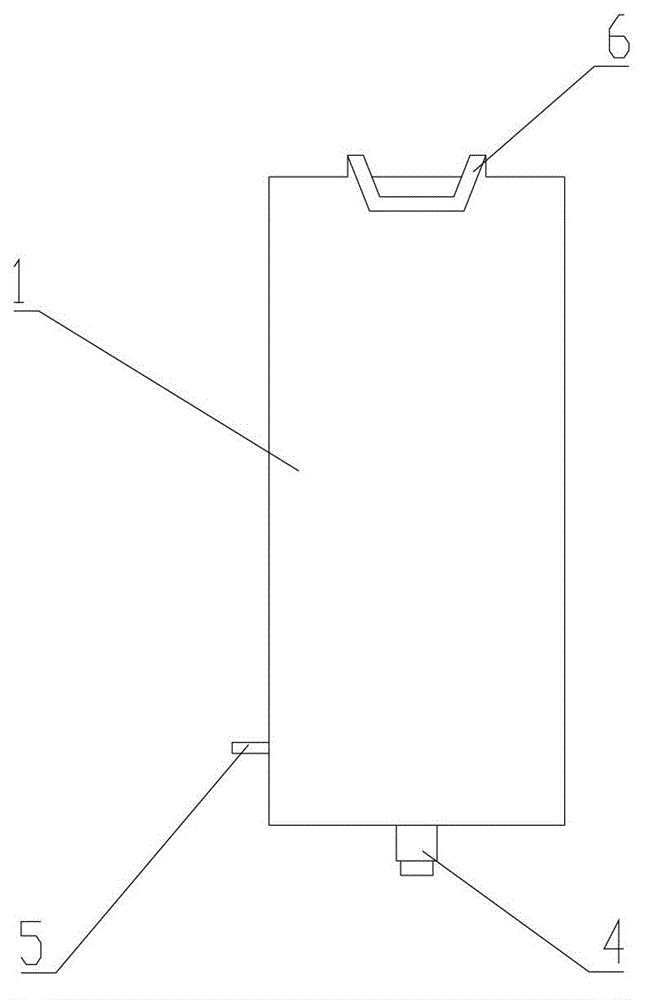

Reverse two-stage filtration method and filtration device for aluminum water

A filter device and stage filter technology, which is applied in the direction of filter separation, separation methods, chemical instruments and methods, etc., can solve the problems of improving the filter effect and reducing costs at the same time, and achieve improved slag removal effect, high purity, and maintenance Effect of filter pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] First let the aluminum water pass through a ceramic filter plate from top to bottom, and then pass through another ceramic filter plate from bottom to top. Under the action of the inner spiral filter channel, the aluminum water rotates forward, and the temperature of the aluminum water is controlled at 690°C. The aluminum water flow rate is controlled at 450kg / min.

Embodiment 2

[0039] First let the aluminum water pass through a ceramic filter plate from top to bottom, and then pass through another ceramic filter plate from bottom to top, and the aluminum water rotates forward under the action of the inner spiral filter channel to control the temperature of the aluminum water at 720 ° C The flow rate is controlled at 500kg / min.

Embodiment 3

[0041] First, let the aluminum water pass through a ceramic filter plate from top to bottom, and then pass through another ceramic filter plate from bottom to top. Controlled at 550kg / min.

[0042] According to embodiment 1, 2, 3 each aluminum water is filtered 10 times respectively, and the aluminum water after filtering is carried out the slag removal effect inspection, and the inspection method is: sample mold size is 75mm * 135mm * 30mm, casting sample gets aluminum For the ingot sample, the sample is polished with emery and then sent to the sulfuric acid tank for anodic oxidation treatment, revealing the slag inclusions, making it easy to identify, and counting the number of inclusions. None of the samples obtained showed defects such as porosity, pores, and slag inclusions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com