Vanadium extraction cold pressing block and preparation method and applications thereof and vanadium extraction method

A technology of cold briquetting and dry dust removal, which is applied in the direction of manufacturing converters and improving process efficiency, can solve the problems of long process, large site occupation, and long preparation time, and achieve high mechanical strength and cold compaction strength, The effect of improving the oxidation rate and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

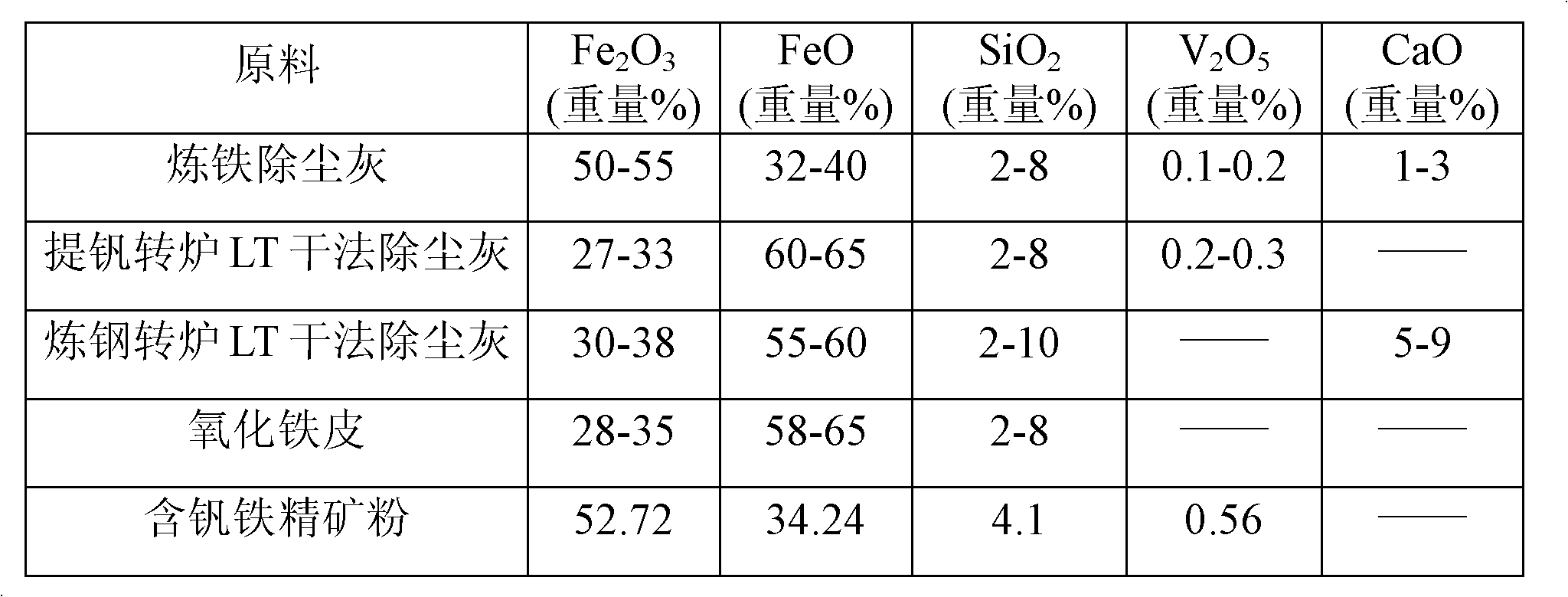

[0015] The invention provides a method for preparing vanadium-extracting cold briquetting, which is characterized in that the method comprises uniformly mixing dedusting ash, iron oxide scale and binder, pelletizing the obtained mixture to obtain wet pellets, and then drying the wet pellets , based on the total weight of the mixture, the amount of dust removal ash is 65-95% by weight, preferably 70-80% by weight; the amount of iron oxide scale is 2-32% by weight, preferably 15-25% by weight % by weight; the amount of the binder is 3-33% by weight, preferably 5-15% by weight.

[0016] When the amount of binder is in the range of 15-33% by weight, it will increase the cost of vanadium extraction cold briquette preparation to a certain extent, therefore, based on the total weight of the mixture, the amount of binder is preferably 5-15% by weight.

[0017] According to the preparation method provided by the present invention, the mixing only needs to make the mixture appear unifo...

Embodiment 1

[0038] This example is used to illustrate the vanadium extraction cold briquette provided by the present invention and its preparation method.

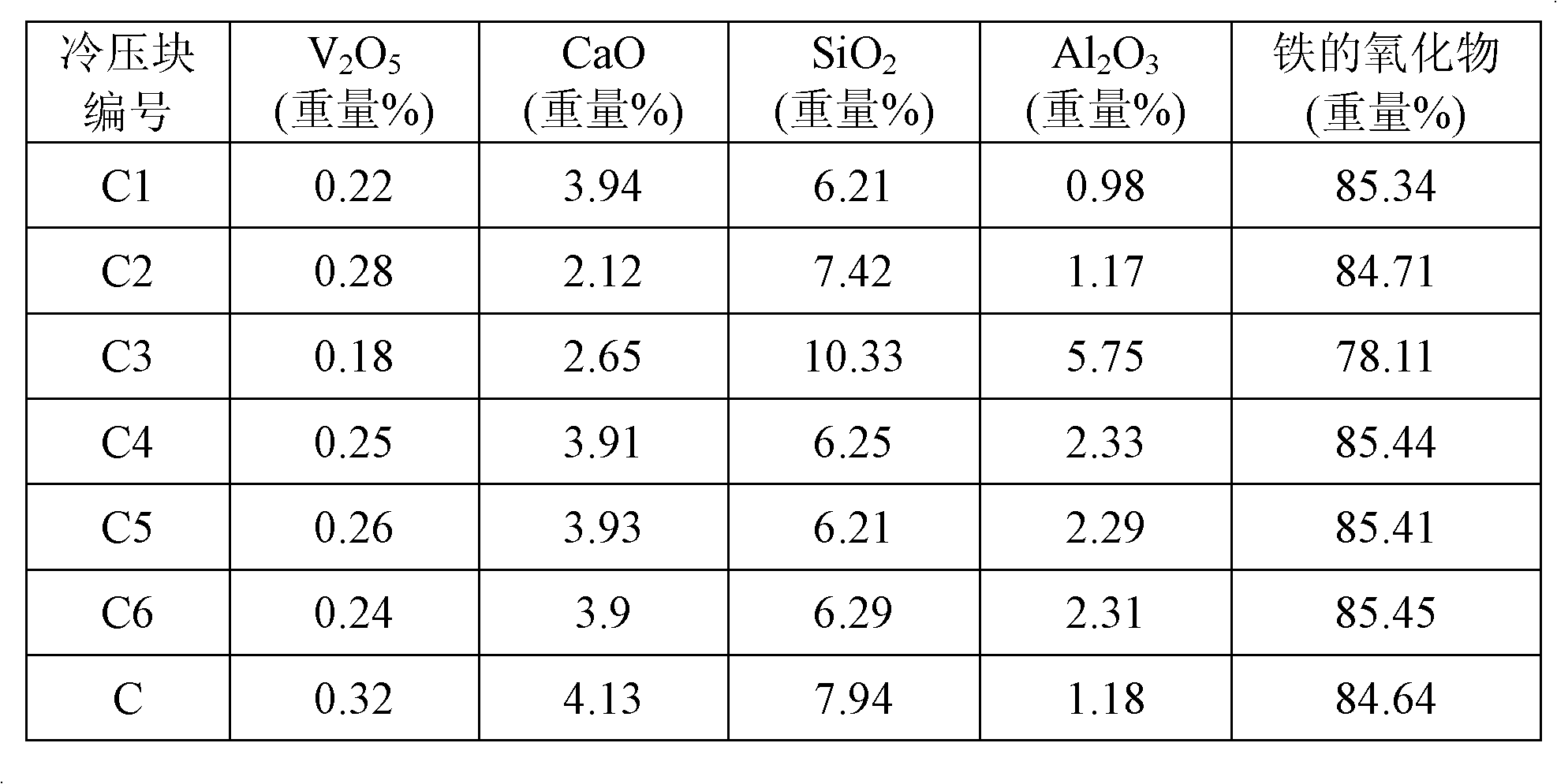

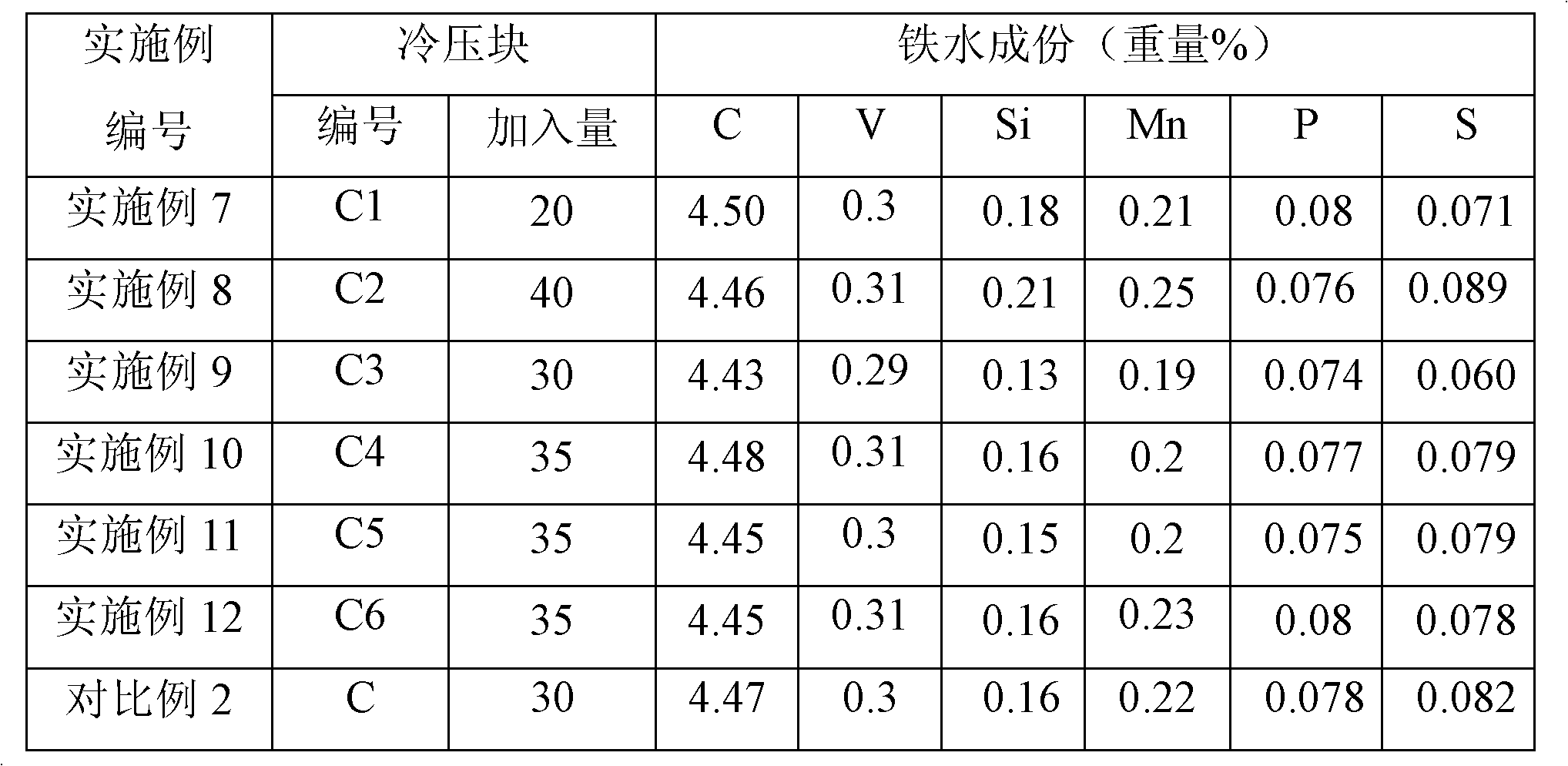

[0039] Iron-making dust, iron scale and binder (the weight ratio of ball clay and boron modified phenolic resin is 1:1) are sent into the disc mixer according to the weight ratio of 65:32:3 for mixing and stirring, Mix evenly after 10 minutes, and transport the mixed mixture to the roller briquetting machine for pelletizing. The pressure of the roller briquetting machine is 15MPa / cm 2 , the prepared wet balls are sieved on the vibrating sieve with an aperture of 10 mm to obtain an oversize material with an average particle size of 30 mm, and the ball forming rate is 95%. Dry in a grate dryer at a drying temperature of 250°C and a drying time of 3 hours to obtain the finished cold briquette product C1. SiO in cold briquette C1 2 , CaO, V 2 o 5 、Al 2 o 3 The contents of iron and iron oxides are shown in Table 2. The mechanical st...

Embodiment 2

[0041] This example is used to illustrate the vanadium extraction cold briquette provided by the present invention and its preparation method.

[0042] Vanadium extracting converter LT dry dust removal, steelmaking converter LT dry dust removal, iron scale and binder (the weight ratio of ball clay and boron modified phenolic resin is 1.5: 1) is 45: 40 according to weight ratio: 2:3 into the disc mixer for mixing and stirring, after 10 minutes, mix evenly, and send the mixed mixture to the roller briquetting machine for pelletizing, the pressure of the roller briquetting machine is 15MPa / cm 2 , sieve the wet ball on a vibrating screen with an aperture of 10mm, the average particle size of the prepared wet ball is 30mm, and the ball forming rate is 93%. Dry in a drying machine at a drying temperature of 300° C. and a drying time of 3 hours to obtain the finished product C2 of cold briquetting. SiO in cold briquette C2 2 , CaO, V 2 o 5 、Al 2 o 3 The contents of iron and iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com