Method for selectively leaching nickel and molybdenum from nickel-molybdenum ore

A nickel-molybdenum ore, selective technology, applied in chemical instruments and methods, improvement of process efficiency, inorganic chemistry, etc., can solve the problems of incomplete leaching of molybdenum, low utilization rate of nickel, large consumption of oxidant and acid, etc., to achieve The effect of reducing the difficulty of impurity removal, reducing production costs, and solving pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

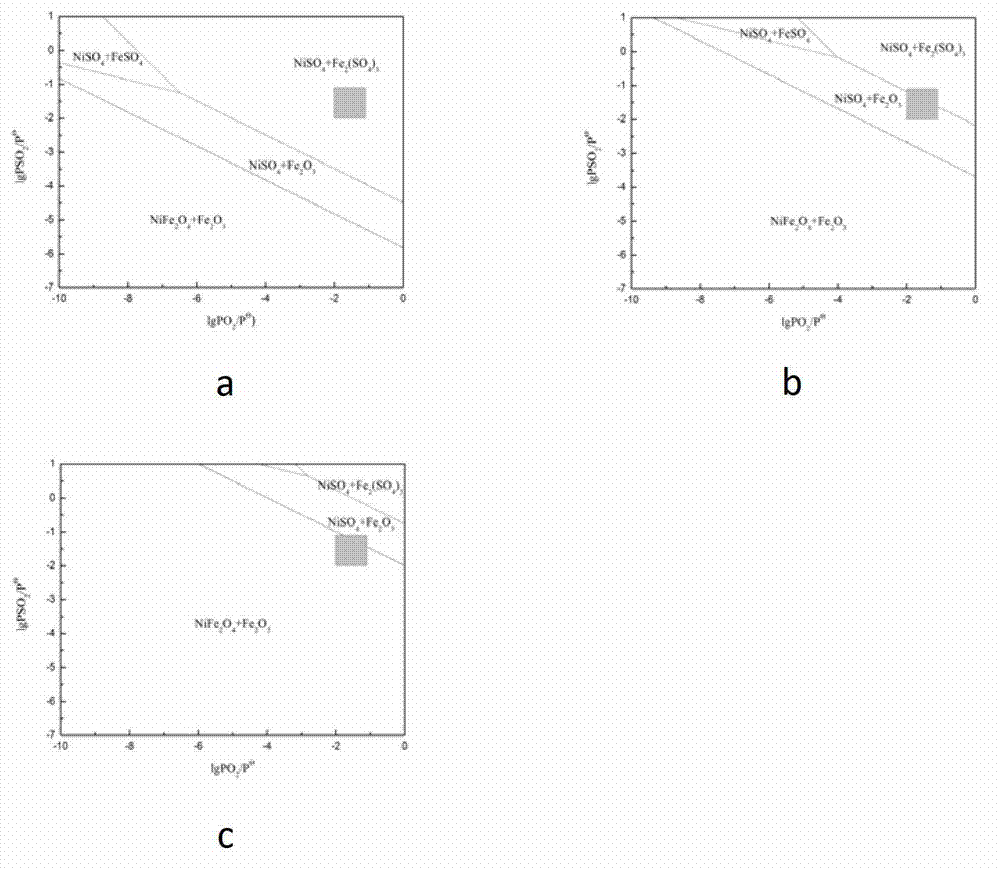

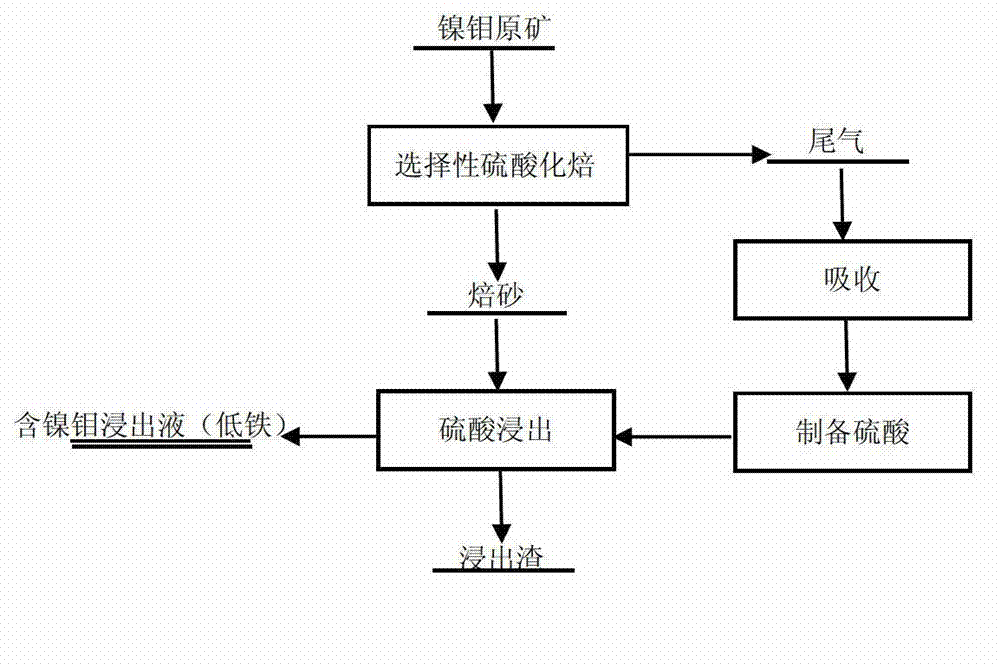

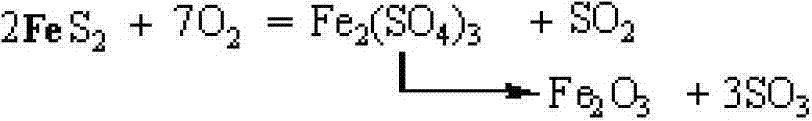

Method used

Image

Examples

Embodiment 1

[0049] The processed nickel-molybdenum ore contains 7.2% molybdenum, 3.6% nickel and 12.2% iron. Weigh 100g of nickel-molybdenum ore under air conditions, control the oxygen concentration in the furnace atmosphere to 2%~10%, sulfur dioxide concentration 1%~6%, and roast at 650℃ for 2.5h. Weigh 35g of roasted ore into 140ml of sulfuric acid solution with a sulfuric acid concentration of 2.5mol / L, leaching for 3h at 80°C, and filtering to obtain a nickel-molybdenum leaching solution. The leaching rate of nickel is 92.8%, the leaching rate of molybdenum is 96.7%, and the leaching rate of iron is only 16.5%. After the roasting tail gas is cooled and collected by a high-temperature water-cooled dust collecting device, it is passed into a 0.3mol / L ethylenediamine solution, and the initial pH value is adjusted to 7.3 with phosphoric acid, SO 2 The absorption rate is above 98%. The desorption rate of the absorption solution reaches 93% at 103°C. After desorption, the concentration of ...

Embodiment 2

[0051] The processed nickel-molybdenum ore contains 5.6% molybdenum, 3.1% nickel and 14% iron. Weigh 60g of nickel-molybdenum ore in oxygen-enriched air with an oxygen concentration of 40%, control the atmosphere in the furnace to have an oxygen concentration of 5% to 20%, and a sulfur dioxide concentration of 5% to 13%, and roast it at 700°C for 1 hour. Weigh 35g roasted ore and add 70ml sulfuric acid solution with a sulfuric acid concentration of 3.5mol / L, leaching for 3h at 85°C, and filtering to obtain a nickel-molybdenum leaching solution. The leaching rate of nickel is 94.6%, the leaching rate of molybdenum is 97.6%, and the leaching rate of iron is only 21%. The sulphur dioxide tail gas produced by roasting is used for direct acid production.

Embodiment 3

[0053] The processed nickel-molybdenum ore contains 6% molybdenum, 2.6% nickel and 13% iron. Weigh 100g of nickel-molybdenum ore under air conditions, control the oxygen concentration in the furnace atmosphere to 2%~10%, sulfur dioxide concentration 1%~6%, and roast at 625℃ for 3h. Weigh 35g roasted ore and add 105ml sulfuric acid solution with a sulfuric acid concentration of 0.5mol / L, leaching for 3h at 70°C, and filtering to obtain a nickel-molybdenum leaching solution. The leaching rate of nickel is 91.6%, the leaching rate of molybdenum is 95.6%, and the leaching rate of iron is only 15.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com