Rotary kiln device for sodium dichromate production by calcium-free calcination

A sodium dichromate, calcium-free roasting technology, applied in the field of rotary kiln, can solve the problems of shortening the oxidative roasting time and low production efficiency, and achieve the effects of shortening the oxidative roasting time, improving the production capacity and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

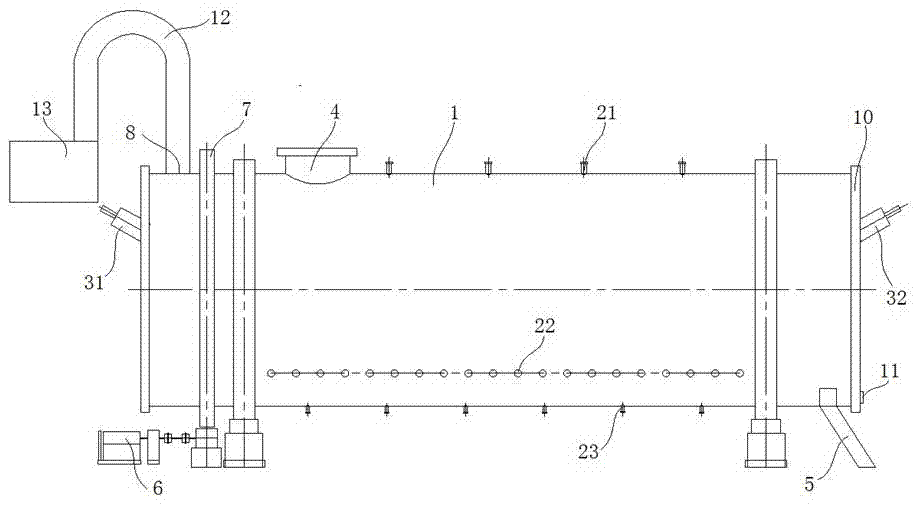

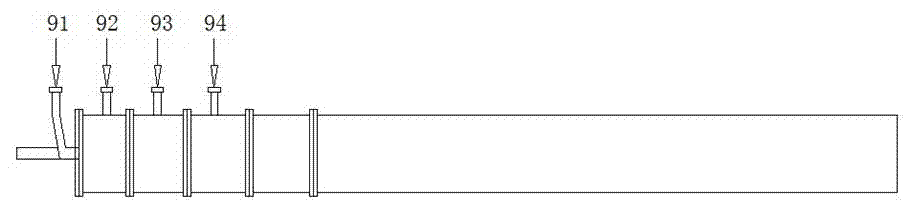

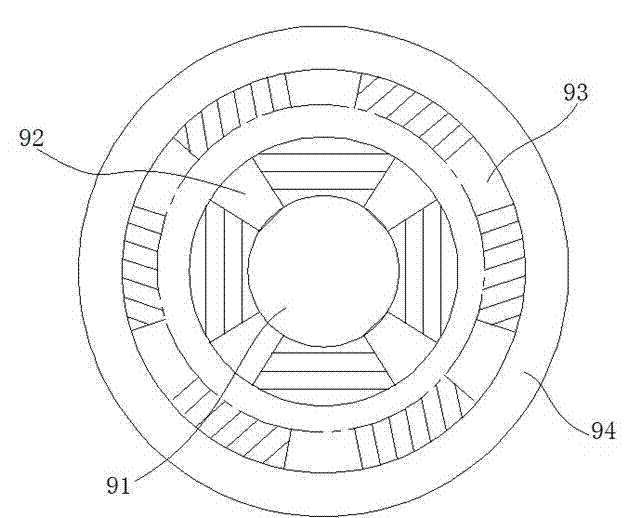

[0031] combine figure 1 , a kind of calcium-free roasting of the present embodiment produces the rotary kiln device that sodium dichromate is used, comprises kiln body 1, top tuyere device 21, side tuyere device 22, bottom tuyere device 23, feed end burner 31, Discharge end burner 32, feeding port 4, siphon high outlet 5, transmission device 6, ring gear 7, flue gas outlet 8, siphon flue 12, fixed flue 13, end cover 10, slag discharge port 11 and spray gun.

[0032] The kiln body 1 of this embodiment is a horizontal rotary kiln with a diameter of φ2.15×9m. The length-to-diameter ratio of the kiln body 1 is 4.2. In the present invention, the length-to-diameter ratio of the kiln body 1 is designed to be 3~6, which is a One of the key improvement points, compared with the conventional rotary kiln with length-to-diameter ratio of 15-20, it is significantly shortened, resulting in less heat dissipation and concentrated heat, which reduces fuel consumption by more than 20%, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com