Carbon fiber heating piece and preparation method thereof

A carbon fiber and heating sheet technology, applied in the field of carbon fiber heating sheet and its preparation, can solve the problems of complex preparation process and high production cost, and achieve the effects of simple preparation process, simple structure, and reduced difference in heating temperature zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The equipment and tools used in this embodiment are as follows:

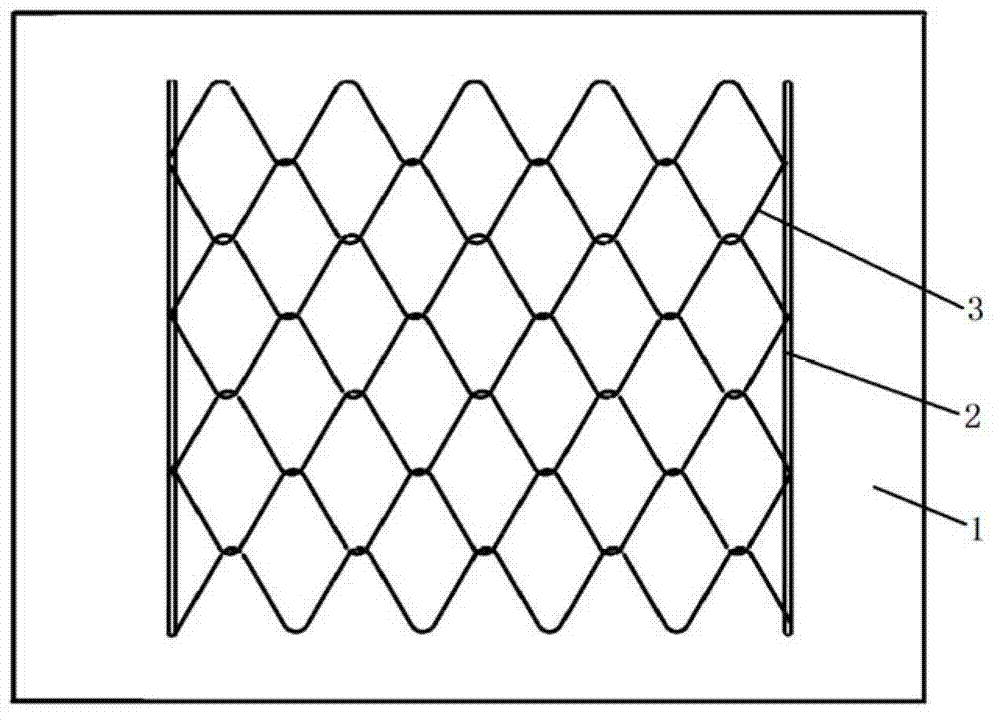

[0032] Self-made electric soldering iron: Use 15W+1A{1N4007} diodes to change the temperature of the electric soldering iron to control the temperature at 180-250°C; special riveting machine for terminals: 543-1 type; electric iron; abrasive tools, divided into upper abrasive tools and A lower abrasive tool, on which a plurality of iron nails arranged in a diamond-shaped network structure is arranged, and on the upper abrasive tool, a plurality of through holes matching the iron nails; an automatic bonding machine.

[0033] The raw materials used in this embodiment are as follows:

[0034] Pure cotton linen lining (requires pure cotton, bonding temperature above 180°, double-point linen lining); pure brass copper mesh (60 mesh pure brass mesh, no rust spots, smooth); mesh hot melt adhesive: H1001W- --30g / m or Y1201W---35g / m; carbon fiber filament (1k, Japan Toray model (T-300)); pure cotton cloth.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com