Inorganic light thermal insulating wallboard and manufacturing method thereof

The technology of a thermal insulation wall panel and a manufacturing method, which is applied in the field of foam concrete block manufacturing, can solve the problems of difficult popularization and use, low technical content, single performance, etc., and achieves good thermal insulation effect, simple process operation and good viscoelastic toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific embodiments.

[0023] Mix 10-30 parts of cement, 40-60 parts of fly ash, and 10-15 parts of waste slag. Add water to form concrete slurry, mix 3 to 5% of cement with inorganic foaming agent and 0.05 for inorganic foaming agent. After ~0.5% of the auxiliary agent is stirred and activated in the air, it is directly added to the above concrete slurry, mixed evenly, and the concrete foams quickly; cast the foamed concrete into the mold; wait for the foamed concrete to solidify by itself; the foamed concrete block is removed Mold, stacking, natural maintenance. The foam concrete blocks will reach the ideal state of use after 8 to 14 days, and the performance indicators will reach and exceed the national mandatory standards of the National Cement Products Standardization Technical Committee (JC / T1062-2007).

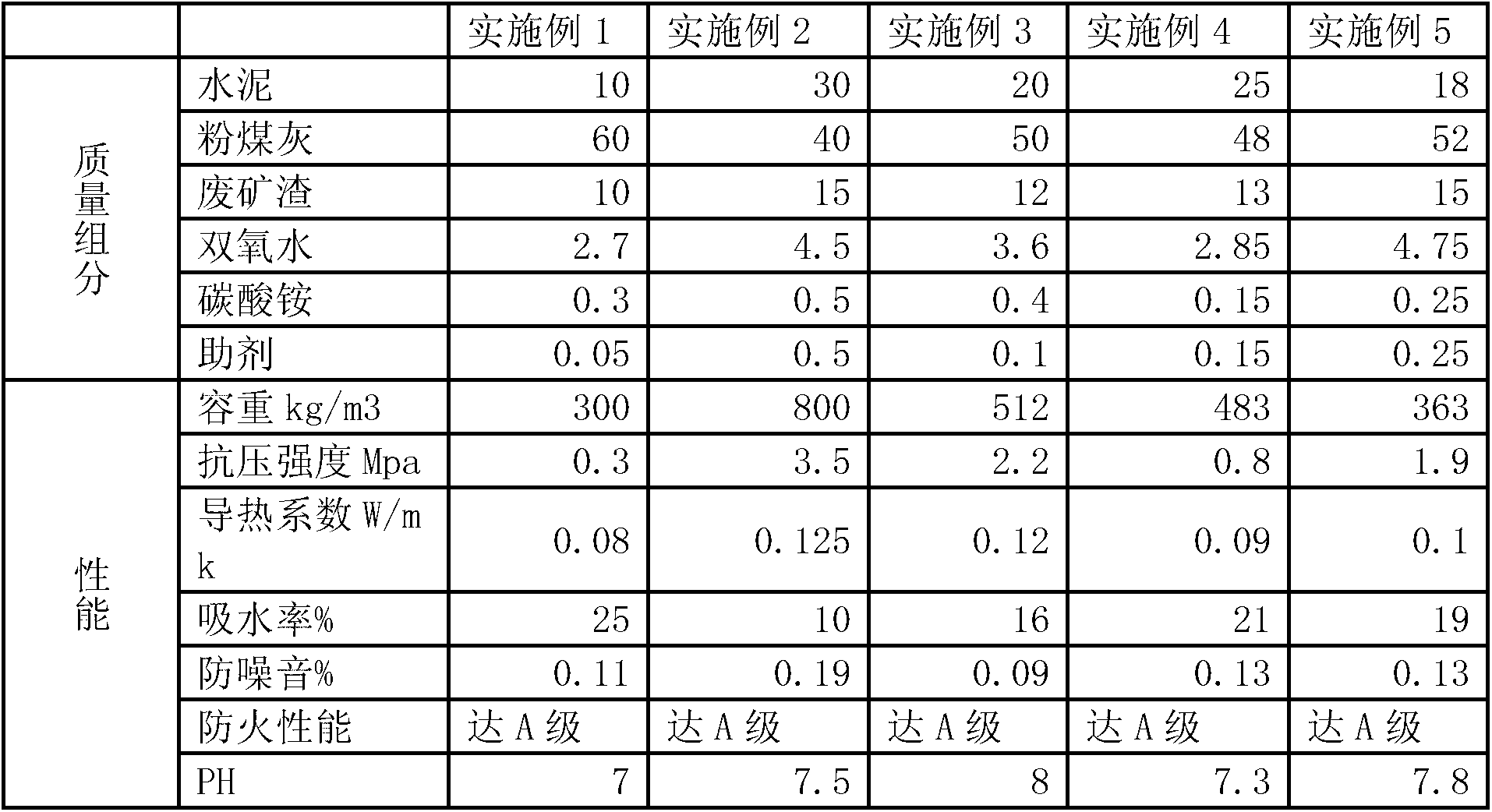

[0024] Examples 1-5 are shown in the following table:

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com