Metallic oxide semiconductor film and preparation method and application thereof

An oxide semiconductor and oxide thin film technology, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, transistors, etc., can solve the problems of high annealing temperature, poor performance of thin-film semiconductors, and poor annealing efficiency, and achieve good stability, Strong performance stability, saving process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

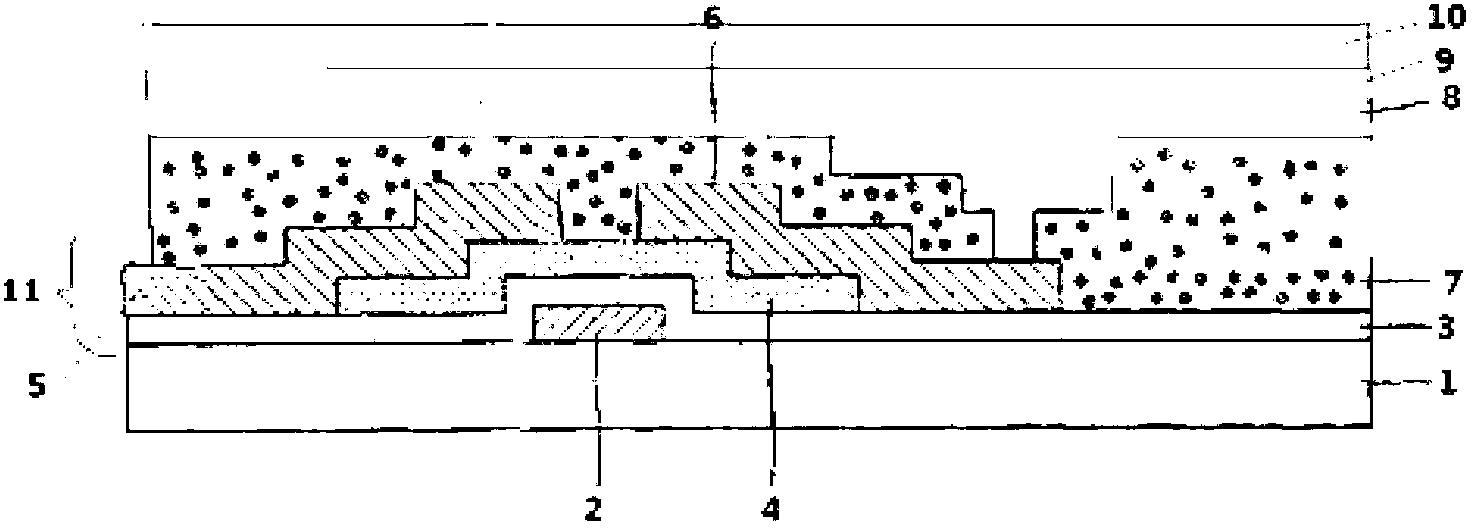

[0053] The metal oxide semiconductor thin film described in this embodiment is an IGZO thin film, which is prepared by the following steps:

[0054] (1) Prepare the desired IGZO metal oxide film by radio frequency magnetron sputtering

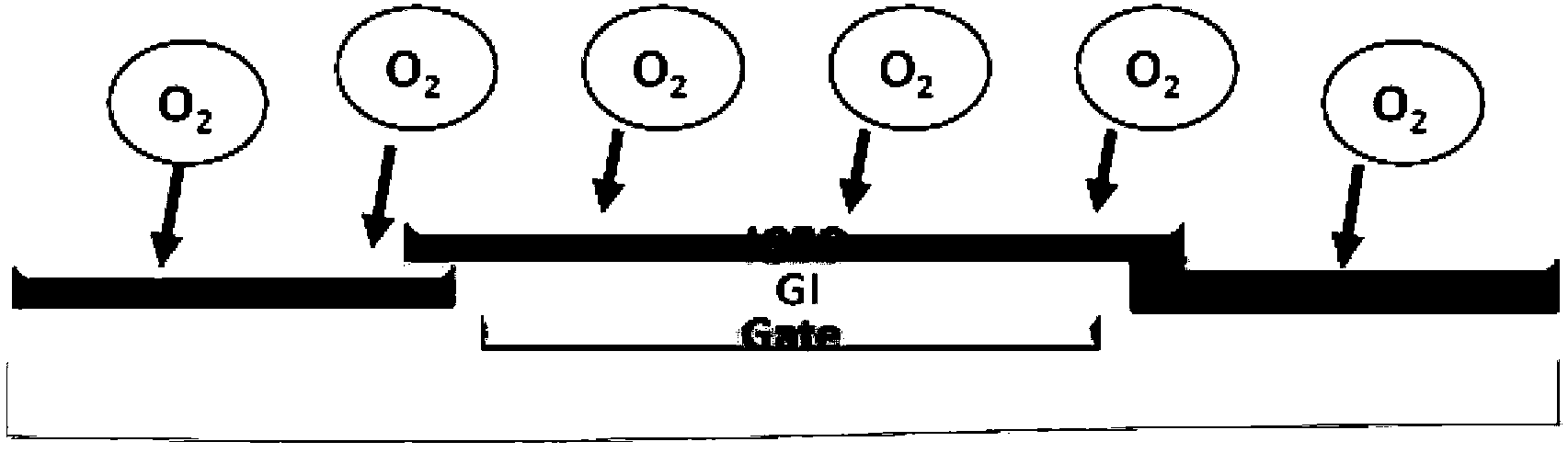

[0055] The specific steps are: a certain proportion of Ar and O is introduced into the vacuum chamber. 2 The mixed gas, apply an electric field between the substrate IGZO targets, and use a high-density magnetic field to scan the IGZO targets. Ar ions hit the IGZO target under the action of an electric field, sputtering atoms or atomic groups of In, Ga, and Zn, and these atoms or atoms are deposited on the glass substrate to form a 30nm thick IGZO film;

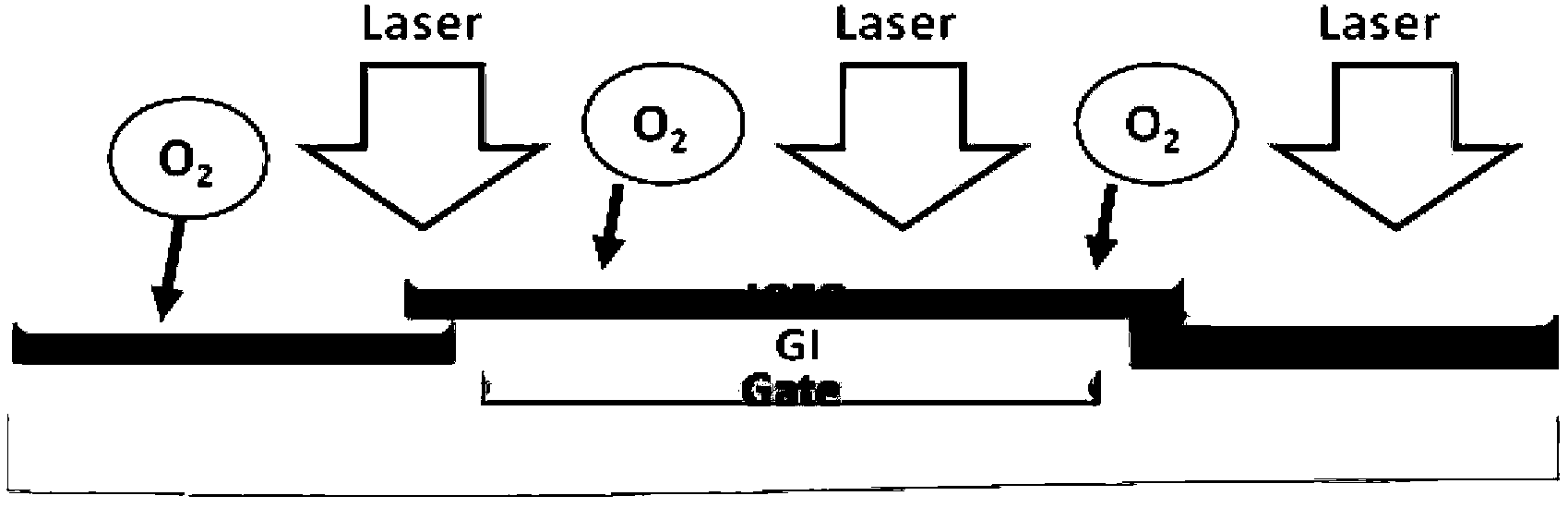

[0056] (2) Laser annealing procedure

[0057] The specific steps are: a certain proportion of N is introduced into the airtight chamber 2 and O 2 The mixed gas, adjust the oxygen content in the airtight chamber to 63%, and place the above-mentioned glass substrate deposited with the IGZO m...

Embodiment 2

[0070] The metal oxide semiconductor thin film described in this embodiment is an IGZO thin film, which is prepared by the following steps:

[0071] (1) Prepare the desired IGZO metal oxide film by radio frequency magnetron sputtering

[0072] The specific steps are: a certain proportion of Ar and O is introduced into the vacuum chamber. 2 The mixed gas, apply an electric field between the substrate IGZO targets, and use a high-density magnetic field to scan the IGZO targets. Ar ions hit the IGZO target under the action of an electric field, sputtering atoms or atomic groups of In, Ga, and Zn, and these atoms or atoms are deposited on the glass substrate to form a 30nm thick IGZO film;

[0073] (2) Laser annealing procedure

[0074] The specific steps are: a certain proportion of N is introduced into the airtight chamber 2 and O 2 The mixed gas, adjust the oxygen content in the airtight chamber to 10%, and place the above-mentioned glass substrate deposited with the IGZO m...

Embodiment 3

[0077] The metal oxide semiconductor thin film described in this embodiment is an IGZO thin film, which is prepared by the following steps:

[0078] (1) Same as step (1) in Example 1;

[0079] (2) Place the above-mentioned glass substrate deposited with IGZO metal oxide film on all O 2 In the closed chamber, the laser annealing is carried out by scanning the strip laser with a wavelength of 800 through the continuous laser, and keeping it for 3-6 minutes. During the scanning process, the metal oxide film absorbs the energy of the laser and raises the temperature to achieve the effect of annealing. Obtain the desired IGZO semiconductor thin film.

[0080] The structure and preparation method of the TFT device prepared in this embodiment using the above-mentioned metal oxide thin film as a semiconductor layer are as described in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com