Multistep effective method for finite element model updating

A model correction, finite element technology, applied in the field of finite element model correction, can solve the problems of model correction technology application limitations, modeling uncertainty, interference and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0046] Specific examples are as follows, and the scope of protection of the present invention is not limited to the following examples.

[0047] 1. Establish a finite element model

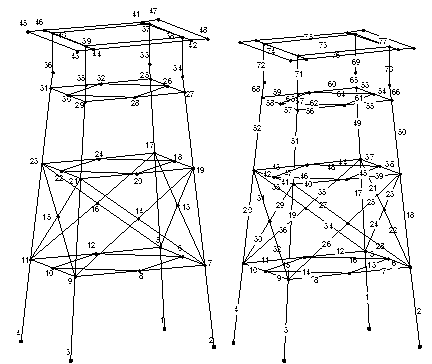

[0048] The embodiment of the present invention is a simplified model of a jacket platform, and the structure is composed of columns, horizontal braces, diagonal braces and decks, etc. There are 72 rod units and 5 surface units, such as figure 1 shown. Use Matlab to write the finite element program and establish the finite element model. The measured model of the structure is simulated by changing the elastic modulus or density of some elements of the finite element model, that is, the stiffness correction coefficient α and mass correction coefficient β of the preset elements.

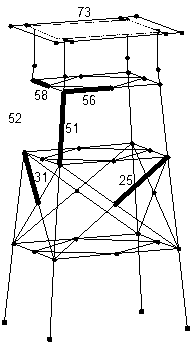

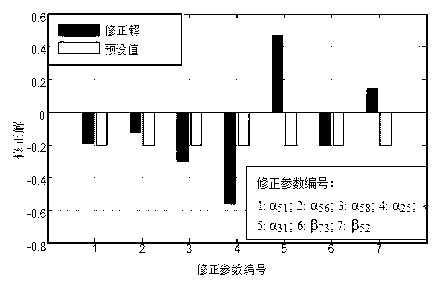

[0049] In this calculation example, different parameters of 7 units are set as objects, such as figure 2 As shown, the default correction coefficient values are -0.2. It is assumed that the measured model only recogn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com