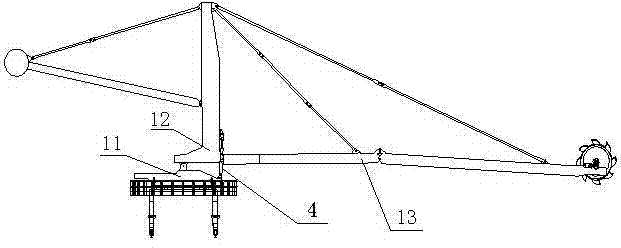

Safety precaution method and system for pitching mechanism of stacker-reclaimer

A technology of safety early warning system and pitching mechanism, which is applied in the direction of fluid pressure actuation system safety, mechanical equipment, loading/unloading, etc. It can solve the problems of limit switch damage, safety accidents, ore and coal dust falling, etc., to achieve Guarantee work safety, solve safety monitoring technical problems, increase safety and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

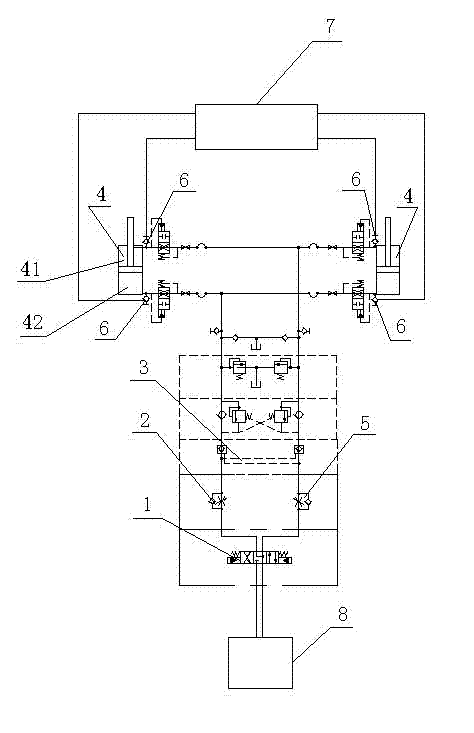

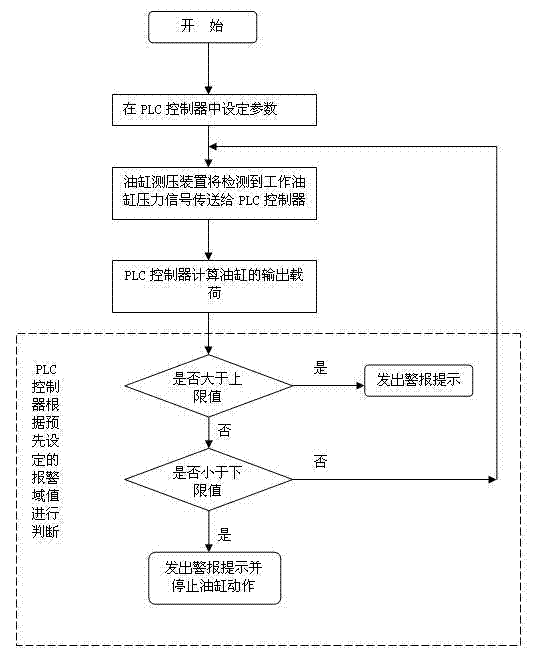

[0035] Such as figure 2 The safety warning system for the stacker-reclaimer pitching mechanism shown includes a pitching mechanism control circuit, and the pitching mechanism control circuit includes an electromagnetic reversing valve 1, a first one-way throttle valve 2, a hydraulic control The one-way valve 3, the hydraulic cylinder 4, the second one-way throttle valve 5, also include the oil cylinder pressure measuring device 6 respectively arranged in the two working chambers of the working oil cylinder 4, and the PLC controller connected with the oil cylinder pressure measuring device 6 7. The PLC controller 7 is also connected with the working oil cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com