Connection joint between basement base plate and underground diaphragm wall

An underground diaphragm wall and basement floor technology, applied in the field of building component nodes, can solve the problems of reducing the bearing capacity of the diaphragm wall, reducing the thickness of the diaphragm wall, increasing the force of the steel plate, etc., achieving good force transmission performance and impermeability performance, reducing Bend Anchor Welding, Effect of Increased Strength and Rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

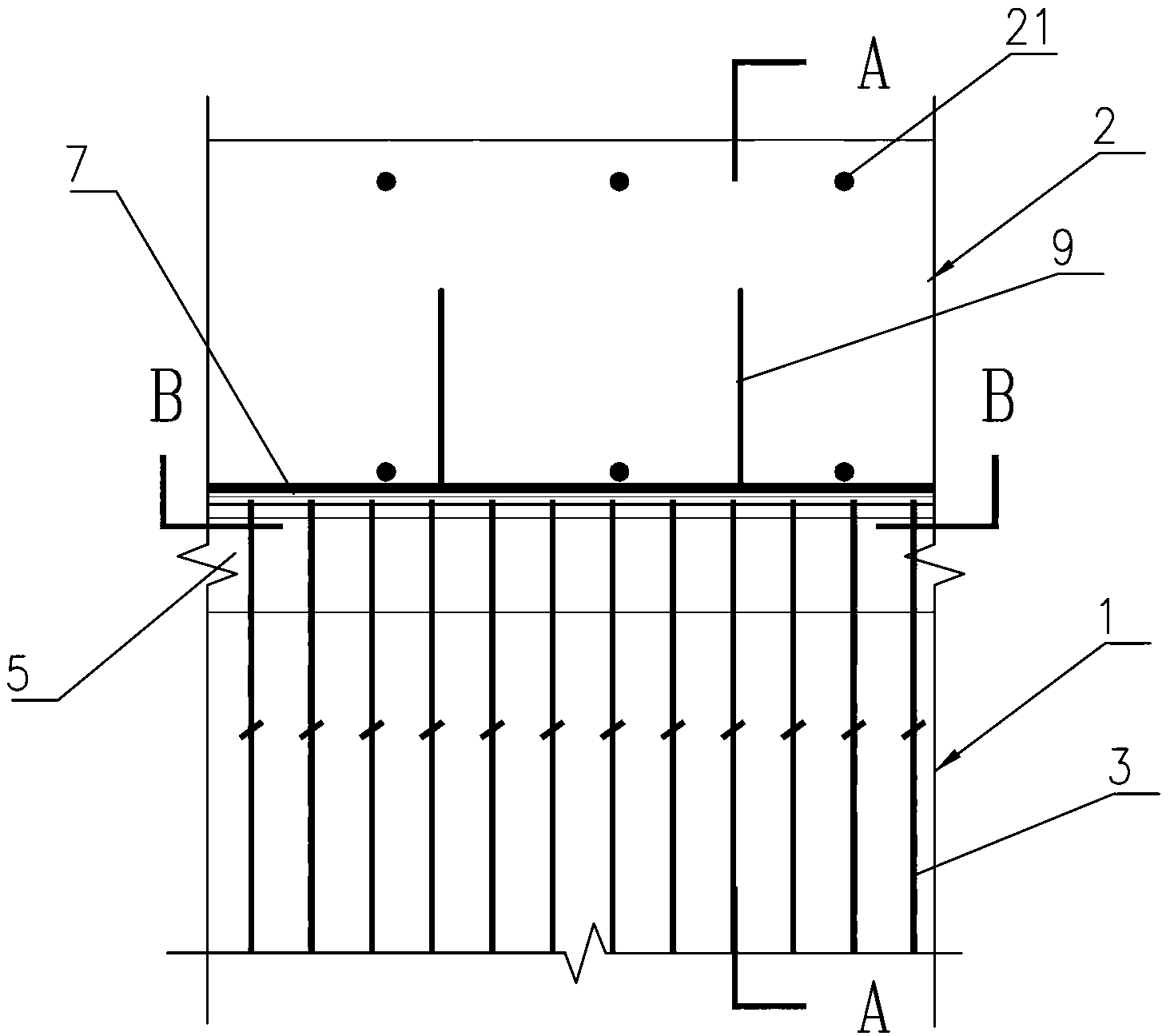

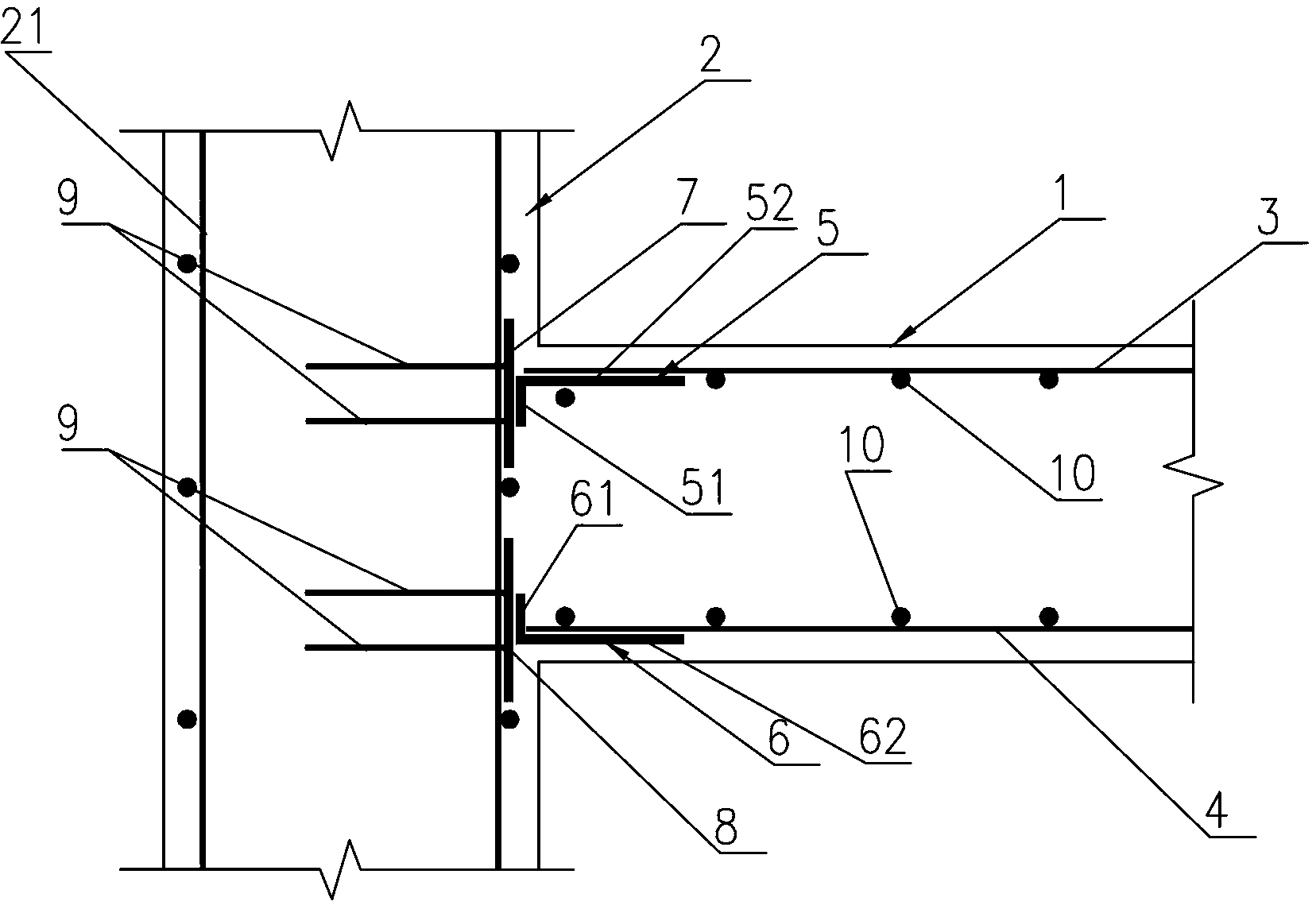

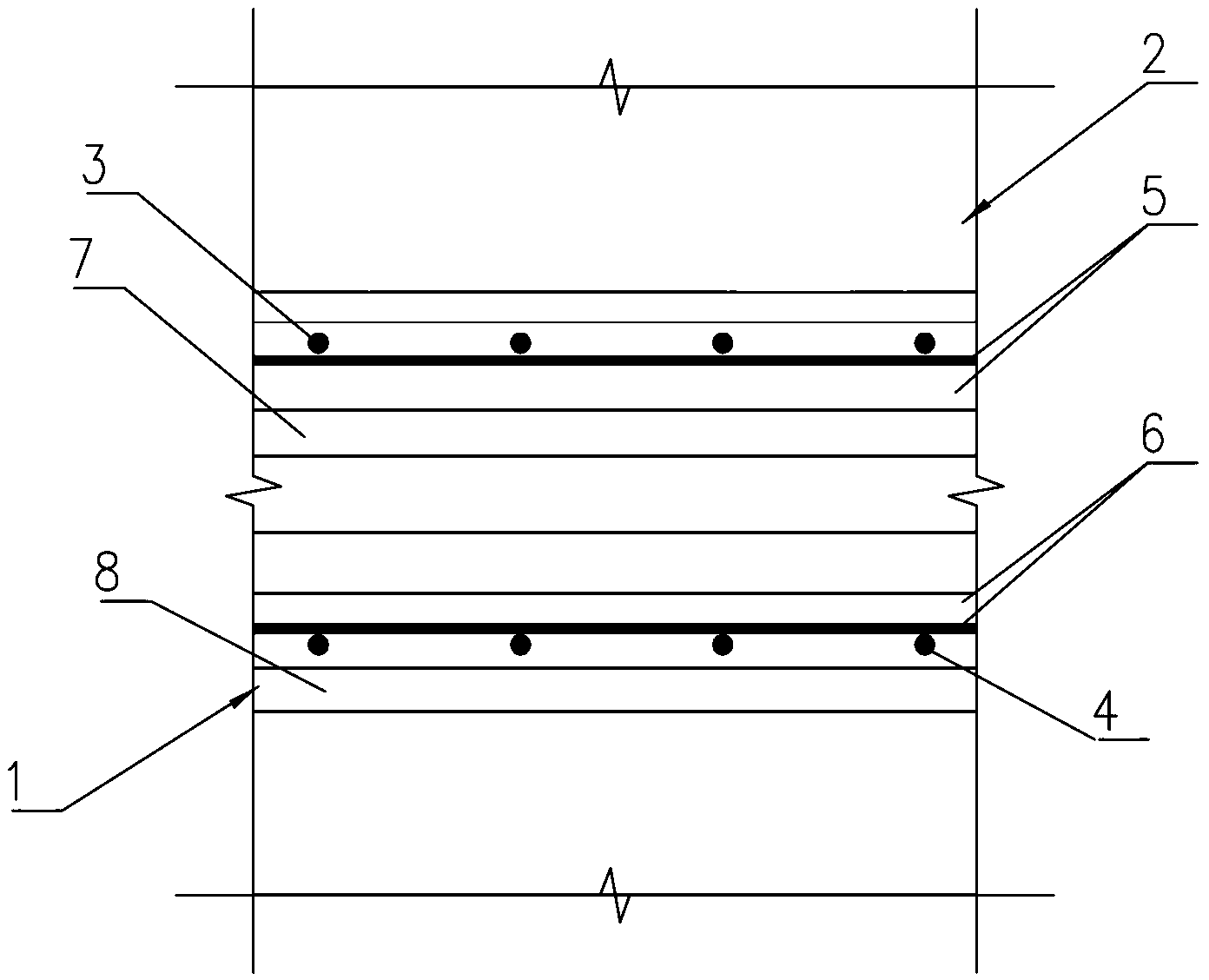

[0026] Such as Figure 1~3 As shown, it is a connection node between the basement floor and the underground diaphragm wall of the present invention, which includes a transition piece, and the transition piece is used to be arranged between the basement floor 1 and the steel plate on the inner surface of the underground diaphragm wall 2, and the underground diaphragm wall 2 It is the same wall as the outer wall of the basement, and the transitional connector is a long profile extending along the length direction of the underground diaphragm wall. For the underground diaphragm wall 2 , the plate surface of the steel plate is connected to its corresponding connection surface, and the transverse reinforcement is extended to the corresponding connection surface to be fixed.

[0027] In this embodiment, the transition connector adopts angle steel, and the transverse reinforcement is composed of the transverse gluten bar 3 located at the top of the basement floor 1 and the transverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com