Polyhedron funnel type air inlet unit for CVD (chemical vapor deposition) equipment and CVD equipment

A gas inlet device and funnel-type technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the adverse effects of material growth speed, crystal quality and raw material utilization rate, complex CVD growth process, Affect crystal quality and other issues to achieve the effect of reducing wall parasitic reactions and easy and effective decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

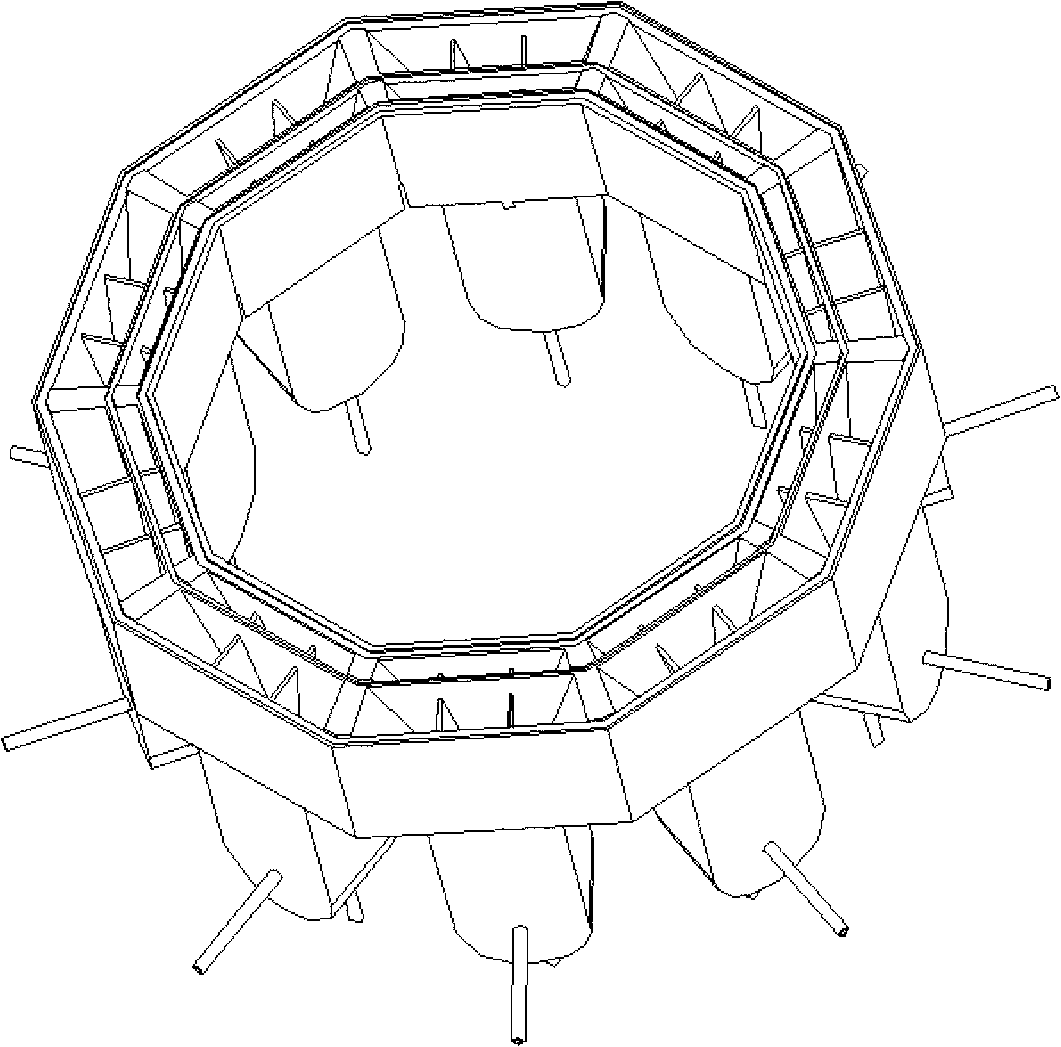

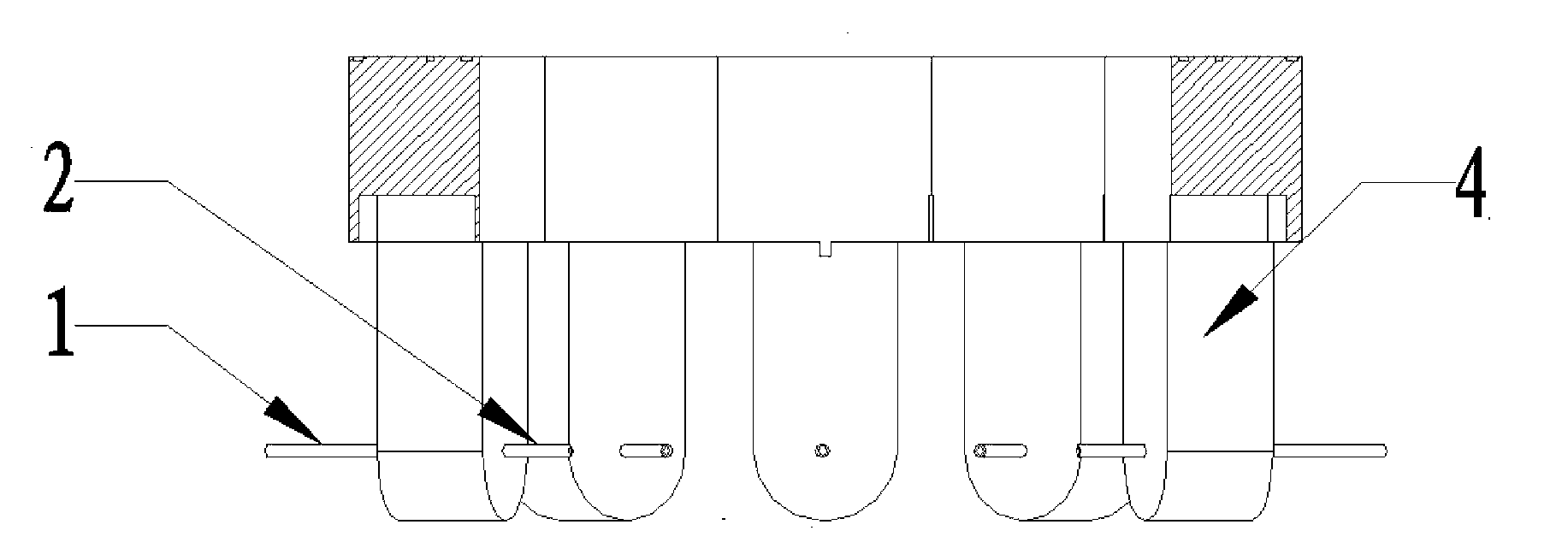

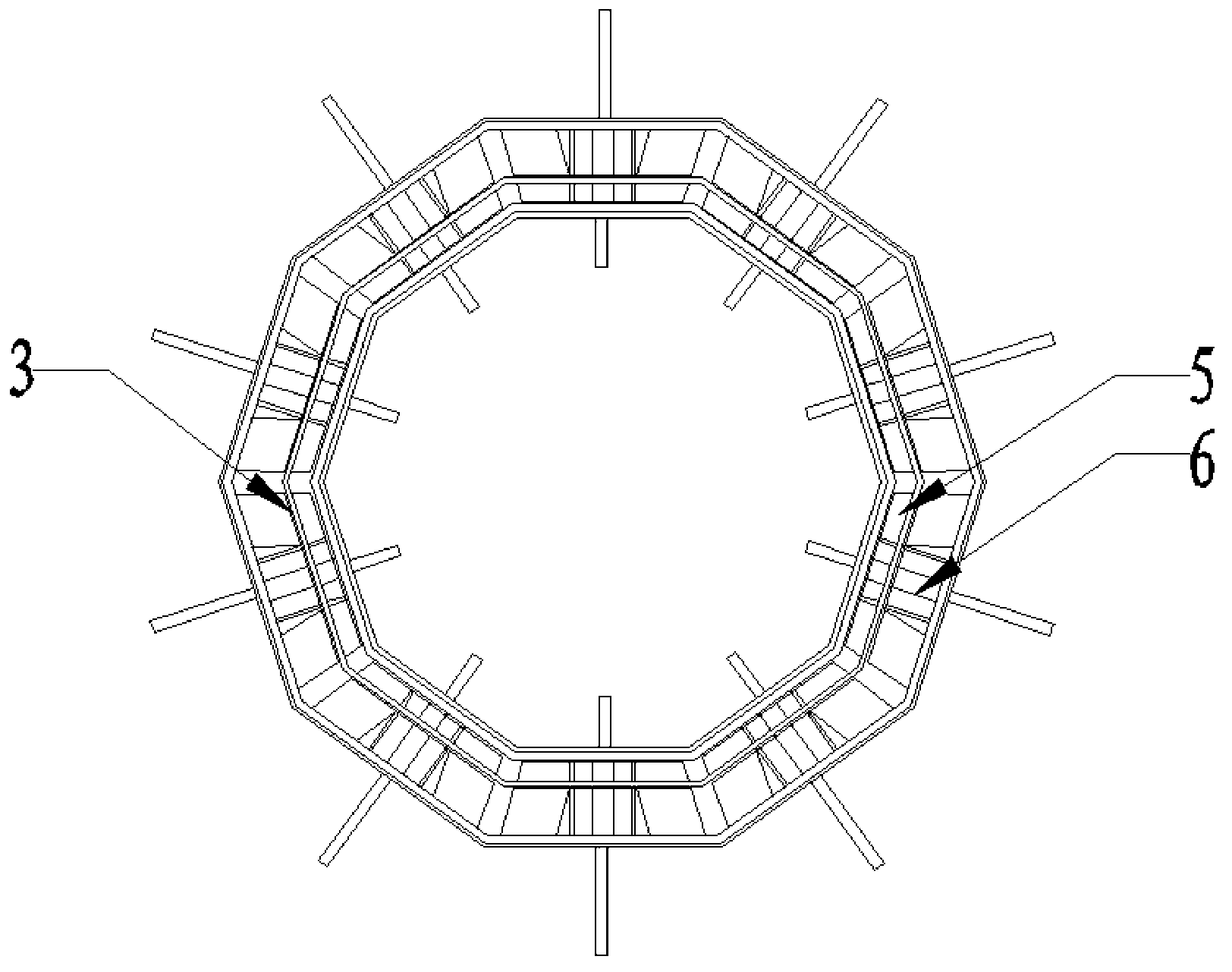

[0031] One aspect of the present invention aims to provide a multi-faceted funnel-type inlet device for CVD equipment, which includes a plurality of funnel bottle inlet nozzles with the same structure and connected around the center to form a polyhedron. The layer baffles are completely isolated into inner and outer air intake chambers, and the inner and outer air intake chambers are also communicated with the first air intake pipe and the second air intake pipe respectively.

[0032] Taking the application of the multi-faceted funnel-type gas inlet device in the growth process of Group III-V semiconductor devices as an example, the aforementioned inner and outer layers of gas inlet chambers can be used as a group V gas inlet chamber and a group III gas inlet chamber respectively.

[0033] Further, the aforesaid funnel bottle inlet nozzle may include two parts, the bottle body and the bottle mouth, wherein one end of the bottle body is a closed end, the other end is fixedly con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com