Method and device for adding alloying elements

A filling device and technology of alloying elements, applied in the field of micro-alloy copper casting, can solve problems such as increased oxygen content in copper liquid, affecting product performance, manual weighing, etc., to save energy costs, improve work efficiency, avoid The effect of air entry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

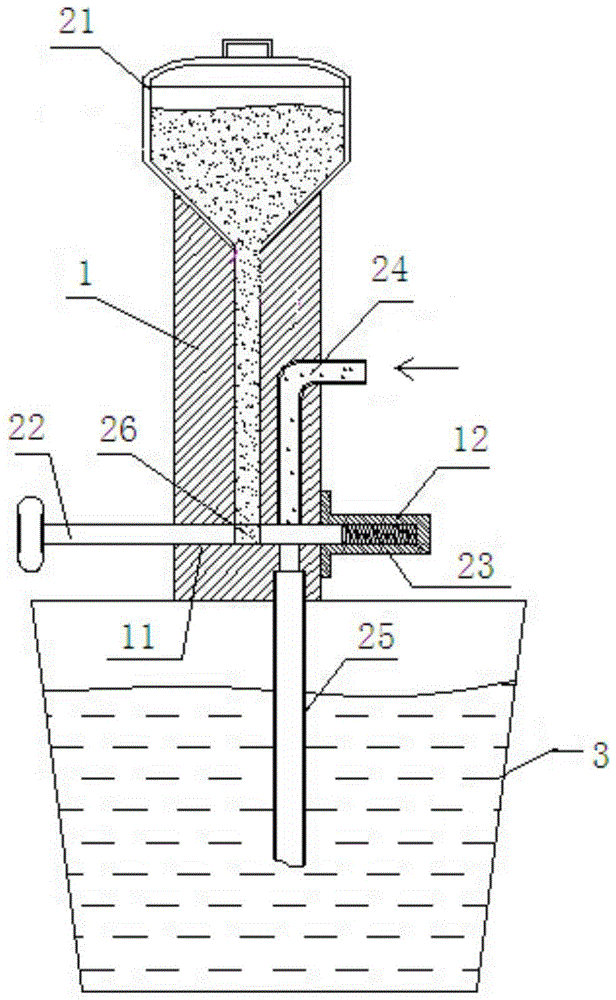

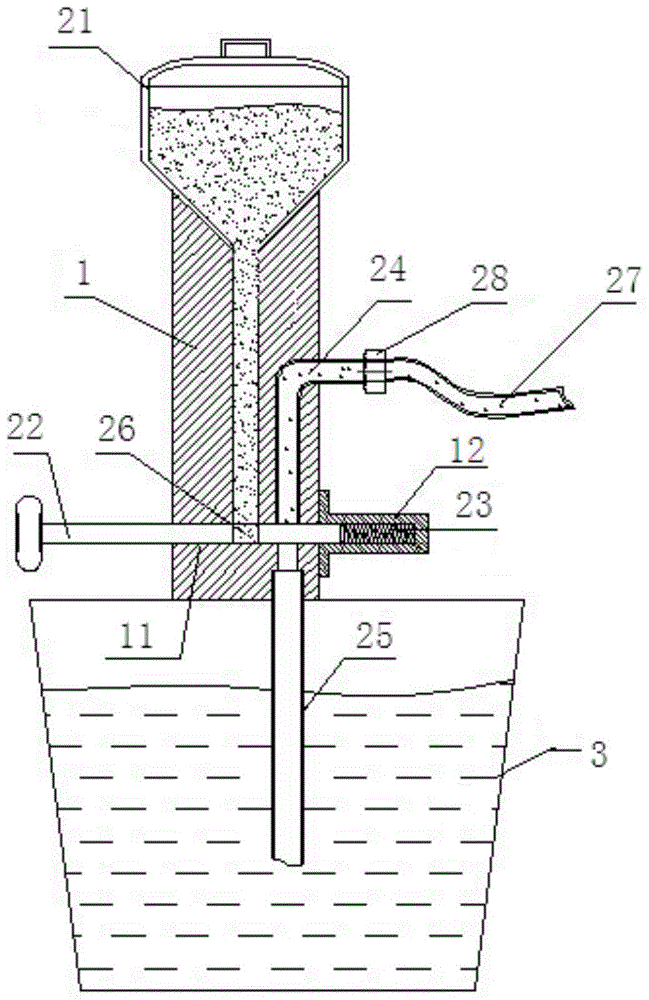

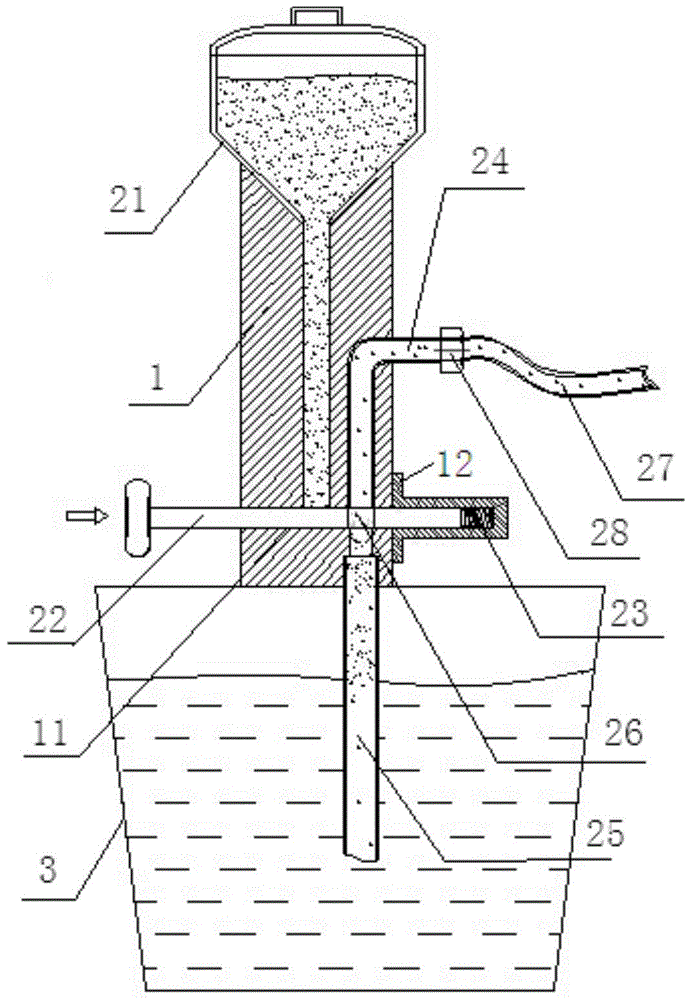

[0040] Such as figure 1 The shown a kind of alloying element filling device comprises device body 1, feeding mechanism 2 and crystallization pool 3; Said feeding mechanism 2 includes feeding funnel 21, feeding push rod 22, spring 23, argon gas injection pipe 24, and graphite tube 25; the horizontal direction in the device body 1 is provided with a push rod chamber 11, and one end of the push rod chamber 11 is provided with a spring seat 12, and the spring seat 12 is provided with the spring 23. The other end of the rod chamber is inserted with the feeding push rod 22, and the front end of the feeding push rod 22 is in contact with the spring 23; the feeding push rod 22 is provided with a material-feeding hole 26 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com