Negative electrode manufacturing device and negative electrode manufacturing method0

A negative electrode and pre-lithiation technology, applied in the field of negative electrode manufacturing, can solve the problems of process loss, difficulty in stabilizing the pre-lithiation degree of the negative electrode structure, etc., and achieve the effect of preventing current loss to the outside.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0172] Embodiment 1: the manufacture of negative electrode

[0173]

[0174] A pre-lithiation bath made of stainless steel with a width, length, and height of 100 cm x 20 cm x 50 cm was provided. The pre-lithiation solution was added to the pre-lithiation bath such that the pre-lithiation solution filled to 20% of the height of the pre-lithiation bath. The pre-lithiation bath was maintained at a temperature of 25 °C.

[0175] By adding LiPF as a lithium salt 6 Added at a concentration of 1M to an organic solvent mixed with ethylene carbonate (EC) and ethylmethyl carbonate (EMC) in a volume ratio of 30:70 and added as an additive at 2% by weight relative to the total weight of the prelithiated solution Fluoroethylene carbonate (FEC) was used to prepare the prelithiation solution.

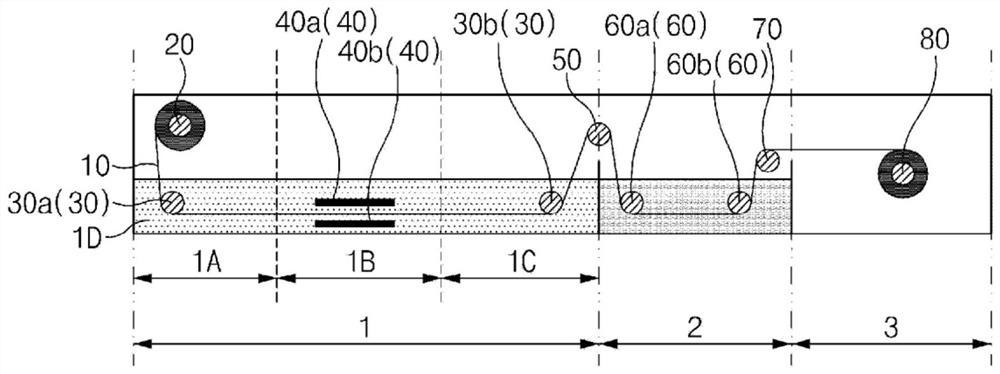

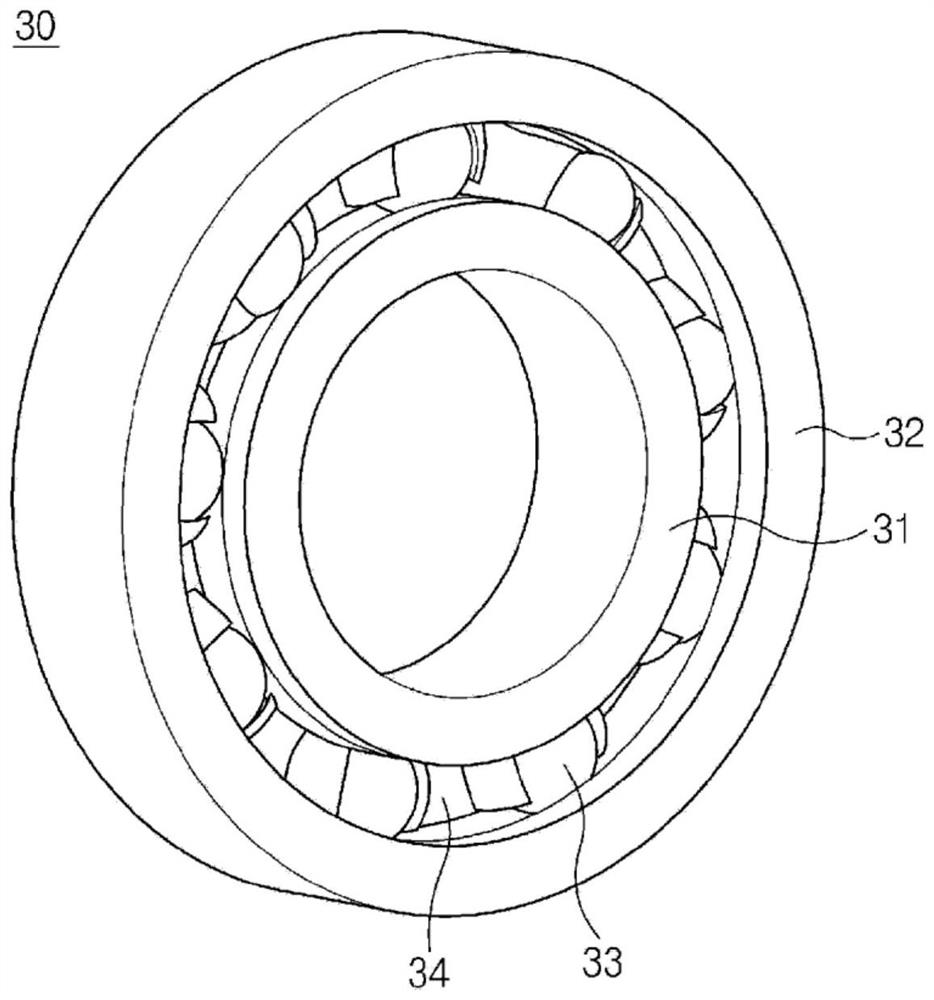

[0176] The pre-lithiation bath is divided into an impregnation section, a pre-lithiation section, and an aging section. In the pre-lithiation solution of the pre-lithiation bath, two pre-lithia...

Embodiment 2

[0199] Example 2: Manufacture of Negative Electrode

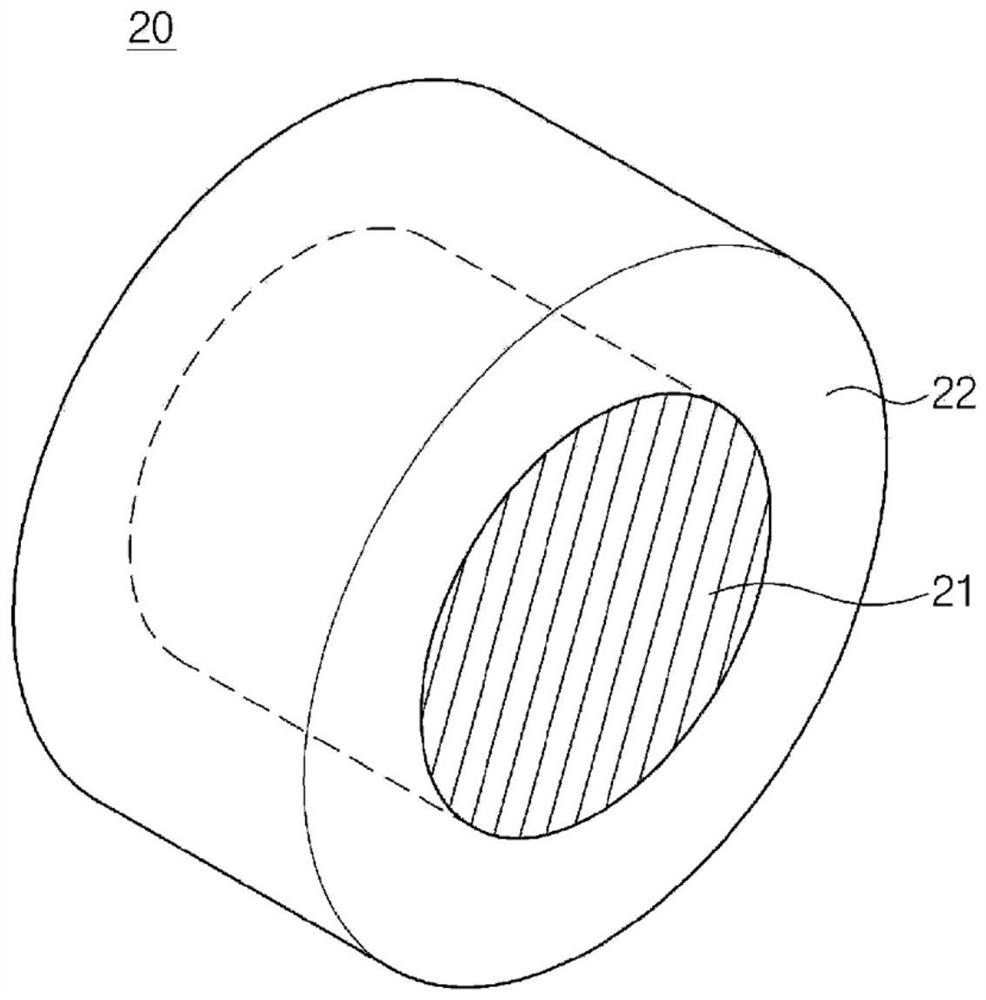

[0200] The negative electrode of Example 2 was fabricated in the same manner using the same apparatus as in Example 1, except that the outer ring of the pre-lithiated roller was made of polytetrafluoroethylene (PTFE, Teflon).

Embodiment 3

[0201] Embodiment 3: the manufacture of negative electrode

[0202] The negative electrode of Example 3 was fabricated in the same manner using the same apparatus as in Example 1, except that the outer ring of the pre-lithiated roll was made of polypropylene (PP).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com