Method for manufacturing anode

A negative electrode and negative active material technology, applied in impregnation manufacturing, electrode manufacturing, battery electrodes, etc., can solve the problem of uniform diffusion of lithium/lithium ions, achieve the effect of improving processing performance and product quality consistency, and improving life characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

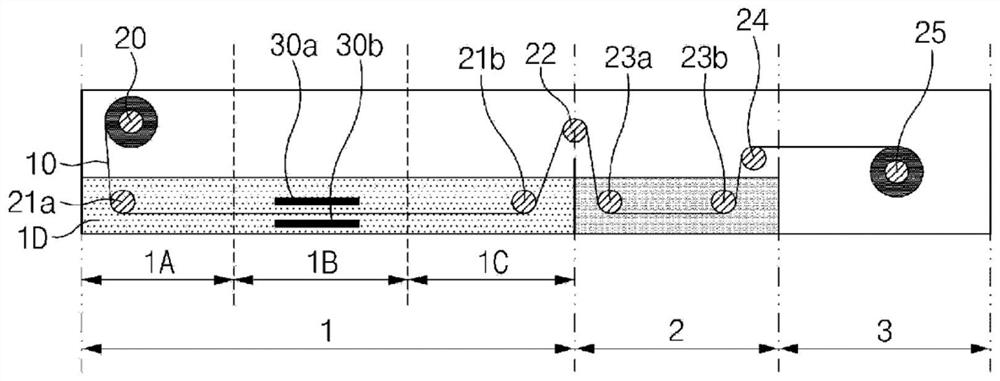

[0113] Embodiment 1: the manufacture of negative electrode

[0114]

[0115] By mixing natural graphite (average particle size (D 50 ): 20μm) and SiO (average particle size (D 50 ): 5 μm) to prepare negative electrode active materials.

[0116] Mix negative active material, Denka black as conductive material, SBR (styrene-butadiene rubber) as binder, and CMC (carboxymethyl cellulose) as thickener in a weight ratio of 92:3:3.5:1 , thus preparing negative electrode slurry.

[0117] The negative electrode slurry was applied to both surfaces of a copper current collector (thickness: 8 μm), and the resulting copper current collector was subjected to roll press and dried in a vacuum oven at 130° C. for 12 hours to form an Negative electrode active material layers (thickness: 70 μm) were formed on both surfaces of the electric device, thereby preparing a negative electrode structure.

[0118] The negative electrode structure was wound on a negative electrode roll made of stainl...

Embodiment 2

[0137] Example 2: Manufacture of Negative Electrode

[0138] The negative electrode of Example 2 was manufactured in the same manner as in Example 1, except that a pre-lithiation bath with a width, length, and height of 90 cm × 20 cm × 50 cm was used, and the impregnation section, pre-lithiation The section, and the aging section are separated by a length ratio of 2:1:1.5, and the negative electrode structure moves through the aging section within 30 minutes.

Embodiment 3

[0139] Embodiment 3: the manufacture of negative electrode

[0140] The negative electrode of Example 3 was manufactured in the same manner as in Example 1, except that a pre-lithiation bath with a width, length, and height of 280 cm × 20 cm × 50 cm was used, and the impregnation section, pre-lithiation The segment, and the aging segment are separated by a length ratio of 2:1:11, and the negative electrode structure moves through the aging segment within 220 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com