Chromium-saved duplex stainless steel with phase-change plasticization effect and preparation method of chromium-saved duplex stainless steel with phase-change plasticization effect

A duplex stainless steel and phase transformation technology, applied in the field of iron and steel alloy materials, can solve the problems of reducing dependence on precious alloy resources, low elongation of thin plates, and difficult thermal processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] In this embodiment, the composition and mass percentage of duplex stainless steel are as follows:

[0012] Cr 14.9%

[0013] Ni 1.9%

[0014] Mn 8.1%

[0015] C 0.026%

[0016] Rare earth Ce 0.10%

[0017] Al 1.2%

[0018] S 0.004%

[0019] P 0.008%

[0020] B 0.001%

[0021] Fe balance

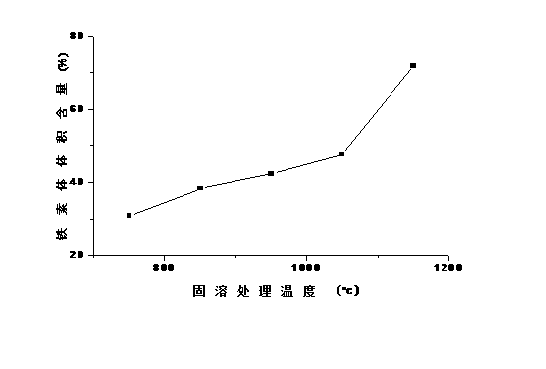

[0022] The traditional conventional smelting process method is adopted, and the rare earth master alloy is put in before casting. After comprehensive measurement calculation and batching melting, pouring molding, hot forging and cold rolling, and a certain solution treatment, the duplex stainless steel alloy material with TRIP effect is finally obtained. The ferrite content varies with the solution temperature. Variation curve such as figure 1 , the room temperature tensile breaking strength of the material is greater than 900MPa, the yield strength is greater than 450MPa, and the elongation at break is greater than 30%.

Embodiment 2

[0024] In this embodiment, the composition and mass percentage of duplex stainless steel are as follows:

[0025] Cr 15.3%

[0026] Ni 2.1%

[0027] Mn 15.0%

[0028] C 0.028%

[0029] Rare earth Ce 0.10%

[0030] Al 2.10%

[0031] Si 1.2%

[0032] S 0.002%

[0033] P 0.009%

[0034] B 0.002%

[0035] Fe balance

[0036] The traditional conventional smelting process method is adopted, and the rare earth master alloy is put in before casting. After comprehensive measurement calculation and batch melting, casting, hot forging, cold rolling, and appropriate solution treatment, a duplex stainless steel with TRIP effect is finally produced. Its room temperature tensile breaking strength is greater than 850MPa, and its yield strength is Greater than 450MPa, elongation at break greater than 30%.

Embodiment 3

[0038] In this embodiment, the composition and mass percentage of duplex stainless steel are as follows:

[0039] Cr 14.8%

[0040] Ni 2.0%

[0041] Mn 12.2%

[0042] C 0.021%

[0043] Rare earth Ce 0.10%

[0044] Al 0.75%

[0045] Si 2.0%

[0046] S 0.003%

[0047] P 0.007%

[0048] B 0.0015%

[0049] Fe balance

[0050] The traditional conventional smelting process method is adopted, and the rare earth master alloy is put in before casting. After comprehensive measurement calculation and batching melting, pouring molding, hot forging and cold rolling, and then a certain solution treatment, the duplex stainless steel alloy material with TRIP effect is finally obtained, and its room temperature tensile breaking strength is greater than 850MPa, yielding The strength is greater than 500MPa, and the elongation at break is greater than 50%.

[0051] This type of duplex stainless steel material has excellent plasticity and excellent corrosion resistance. It can be us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile breaking strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com