Method for extraction of colistin sulphate

A colistin sulfate and extraction method technology, applied in the field of colistin sulfate extraction, can solve the problems of high cost, long cycle, complex process, etc., and achieve the effect of shortening the production cycle and avoiding product activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (7) Ceramic membrane filtration:

[0026] The fermented liquid has a titer of 550,000 U / ml, adjusted the pH to 4.0 with 40% sulfuric acid, and then filtered through a ceramic membrane. The pore size of the ceramic membrane is 0.5 microns, the operating temperature is controlled at 50°C, the membrane inlet pressure is 3bar, and the membrane outlet pressure is 1.5bar.

[0027] During the experiment, water was added twice, and the potency of the dialysate was about 200,000 U / ml; the yield of the ceramic membrane was 98.9%.

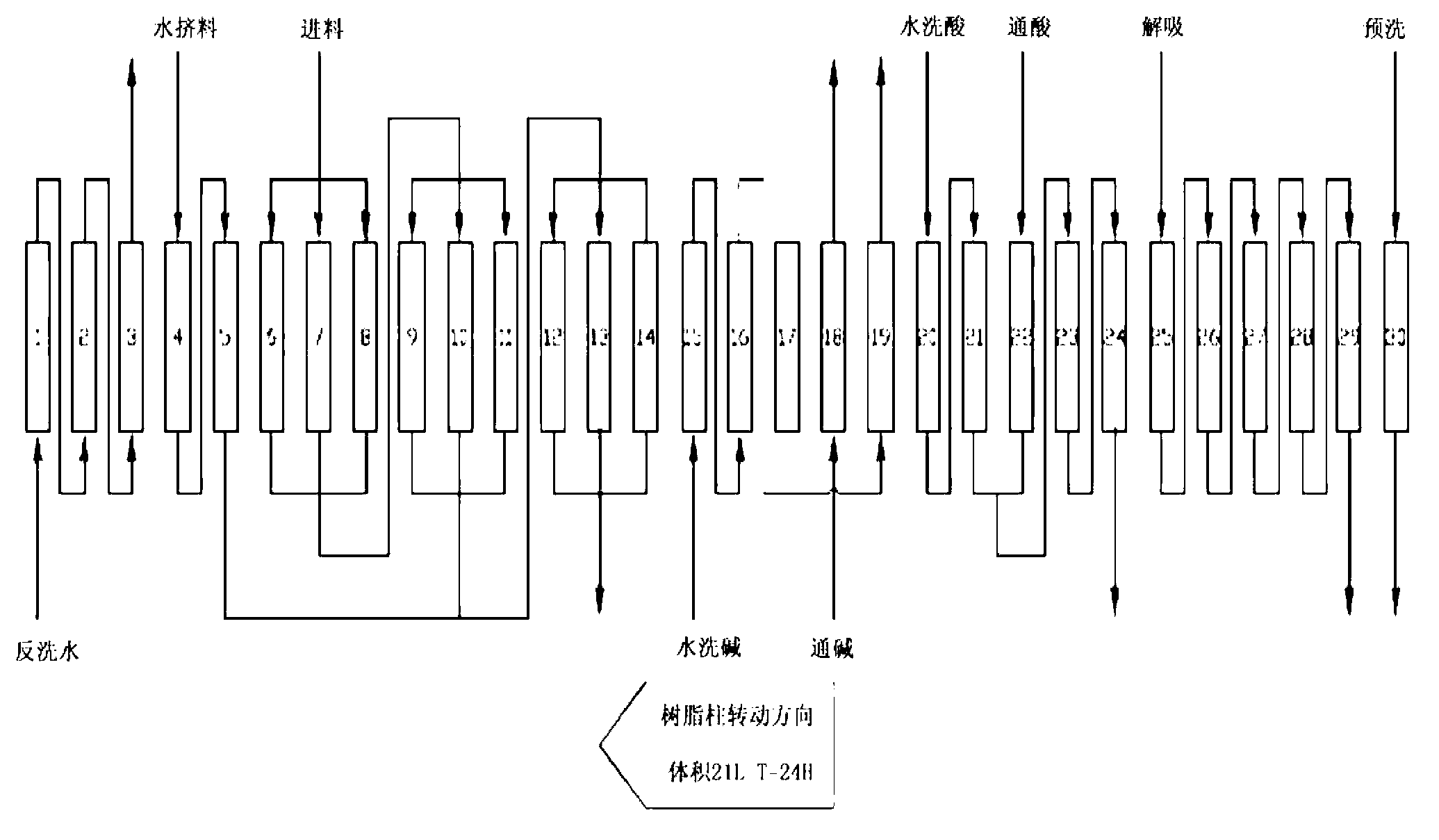

[0028] (8) Continuous moving bed adsorption analysis, resin column connection method see figure 1 :

[0029] The ceramic membrane filtrate enters the continuous moving bed system for adsorption and analysis. The moving bed adopts 30-6 type equipment (30-6 means that the number of columns is 30, and the inner diameter of the valve port of the equipment is 6mm), the rotation period is 24H, and the resin is filled with 21L. The resin is D152 Weakly acid...

Embodiment 2

[0036] (1) Ceramic membrane filtration:

[0037] The fermented broth has a titer of 600,000 U / ml, adjusted the pH to 4.5 with 40% sulfuric acid, and then filtered through a ceramic membrane. The ceramic membrane has a pore size of 0.5 microns, the operating temperature is controlled at 45°C, the membrane inlet pressure is 3.3bar, and the membrane outlet pressure is 1.9bar. During the experiment, water was added twice, and the potency of the dialysate was about 250,000 U / ml; the yield of the ceramic membrane was 99.2%.

[0038] (2) Continuous moving bed adsorption analysis:

[0039] The ceramic membrane filtrate enters the continuous moving bed system for adsorption and analysis. The moving bed adopts 30-6 type equipment (30-6 means that the number of columns is 30, and the inner diameter of the valve port of the equipment is 6mm), the rotation period is 24H, and the resin is filled with 21L. The resin is D152 Weakly acidic cationic resin, the moving bed is divided into feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com