Novel tin-and-indium-containing multi-component cadmium-and-silver-free brazing filler metal

A multi-component, silver solder technology, applied in welding/cutting media/materials, welding media, metal processing equipment, etc. Effects of improved shear strength, reduced cost, and improved processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

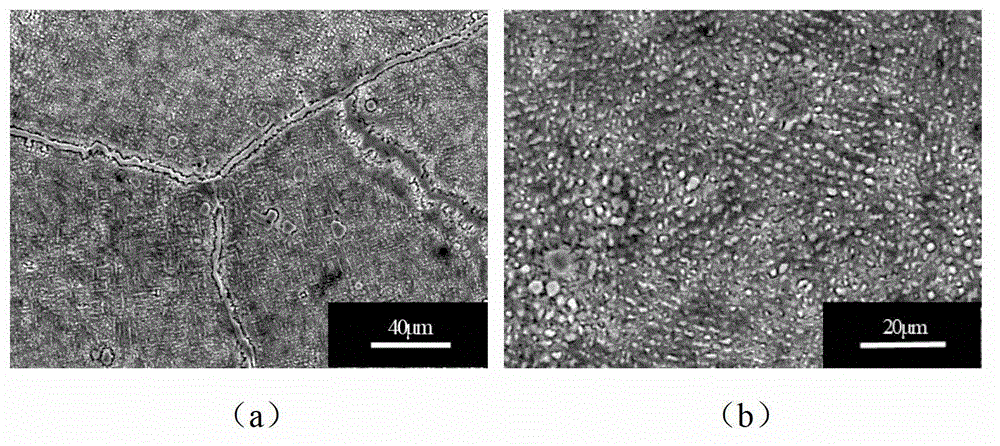

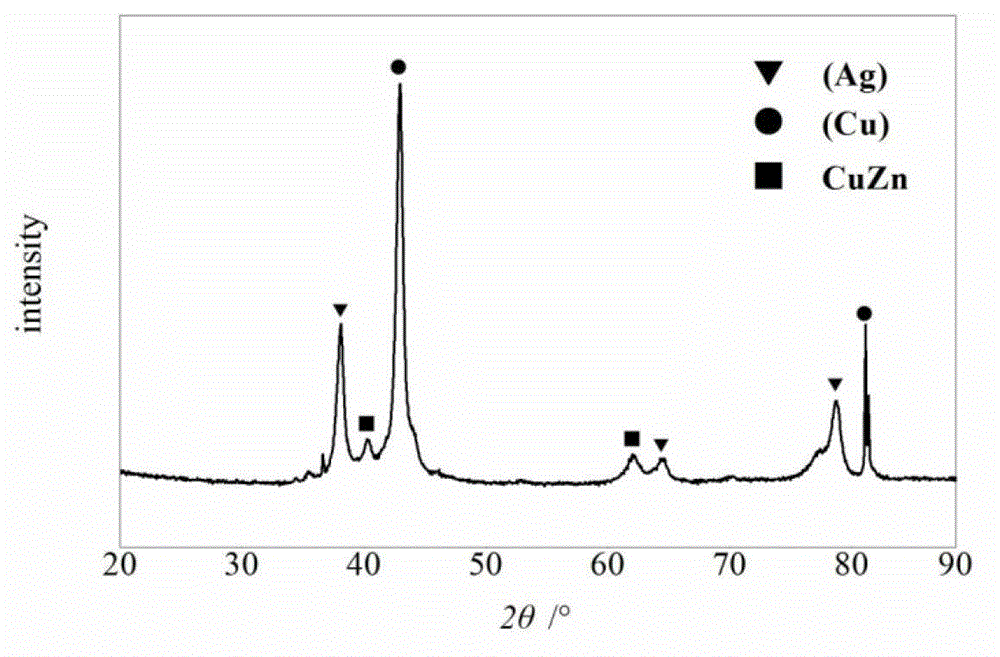

[0020] The mass percentage composition of the solder in this embodiment is: Ag: 25.02%, Cu: 36.18%, Zn: 33.84%, In: 1.04%, and the balance is Sn.

[0021] The solidus temperature of the solder in this embodiment is 713° C., the liquidus temperature is 730° C., and the temperature interval between solidus and liquidus is 17° C. The wetting ratio on the copper is 2.32, the electrical conductivity is 9.6MS / m, the microhardness is 228Hv, and the shear strength of the brazed copper-copper seam is 225.49MPa.

Embodiment 2

[0023] The composition of the solder in this embodiment is: Ag: 25.74%, Cu: 36.65%, Zn: 32.83%, In: 1.20%, and the balance is Sn.

[0024] The solidus temperature of the solder in this embodiment is 701° C., the liquidus temperature is 720° C., and the interval between the solidus and liquidus temperatures is 19° C. The wetting ratio on the copper is 2.63, the electrical conductivity is 9.5MS / m, the microhardness is 215Hv, and the shear strength of the brazed copper-copper seam is 224.62MPa.

Embodiment 3

[0026] The composition of the solder in this embodiment is: Ag: 25%, Cu: 37%, Zn: 34%, In: 1%, and the balance is Sn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com