Preparation method of visible light activated brick-shaped nano-copper ferrite photocatalyst and application thereof

A photocatalyst and nano-iron technology, which is applied in the field of environmental pollution control, can solve the problems of brick-like nano-copper ferrite photocatalyst with no photocatalytic properties and failure to further explore the photoelectric catalytic activity of zinc ferrite and uneven particle distribution. , to achieve the effects of visible light catalytic activity and stability improvement, good optoelectronic properties, and the preparation process is simple and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

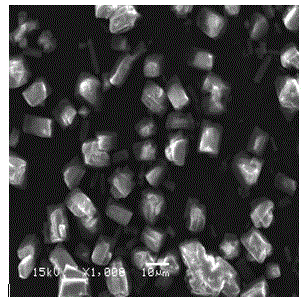

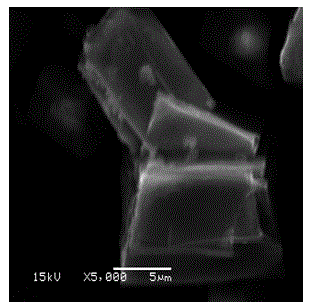

[0027] The preparation method of the brick-like nano copper ferrite photocatalyst activated by visible light of the present invention, the steps are as follows:

[0028] (1) Preparation of brick-like nano-copper ferrite photocatalyst precursor solution: take 100 mL each of 0.1 M copper sulfate solution, 0.2 M ferrous sulfate solution, and 0.1 M sodium oxalate solution, mix the above solutions Magnetic stirring was carried out at 75 °C or 80 °C or 85 °C for 0.5 h or 1 h to make the mixture fully mixed to generate a light yellow iron-copper oxalate precursor solution, and the stirring was continued until no precipitation occurred anymore.

[0029] (2) Washing and drying: After naturally cooling to room temperature (15-30°C), the precipitate in the above step (1) is centrifuged, washed with deionized water, and washed with absolute ethanol (it is better to wash three times each) into Drying in a vacuum oven at 75°C or 80°C or 85°C for 22 h or 24 h or 26 h finally obtained a stabl...

Embodiment 1

[0034]Take 100 mL each of 0.1 M copper sulfate solution, 0.2 M ferrous sulfate solution, and 0.1 M sodium oxalate solution, mix the above solutions, and carry out magnetic stirring at 80 °C for 1 h, so that the mixture is fully mixed to form Light yellow iron copper oxalate precursor solution, keep stirring until no more precipitation occurs.

[0035] (2) Washing and drying: After naturally cooling to room temperature (15-30°C), the precipitate in the above step (1) is centrifuged, washed with deionized water, and washed with absolute ethanol (it is better to wash three times each) into Drying in a vacuum oven at 75°C or 80°C or 85°C for 22 h or 24 h or 26 h finally obtained a stable and uniform light yellow iron-copper oxalate precursor powder.

[0036] (3) Calcination: Calcinate the precursor powder in the above step (2) at 300°C or 400°C or 500°C or 600°C or 700°C in air for 1.5 h or 1 or 2 h or 2.5 h to obtain brown ferric acid copper samples.

Embodiment 2

[0038] According to the preparation method of the present invention in Example 1, only the calcination temperature was changed to 400° C. to obtain a brown visible light-activated brick-like nano-copper ferrite photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com