Chromatographic packing for separating water soluble polymer and protein and preparation method of same

A water-soluble polymer and hydrophilic polymer technology, applied in the field of chromatographic packing, can solve the problems of poor stability and insufficient hydrophilicity, and achieve the effects of low hydrophobicity, excellent resolving power, and high theoretical plate number.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

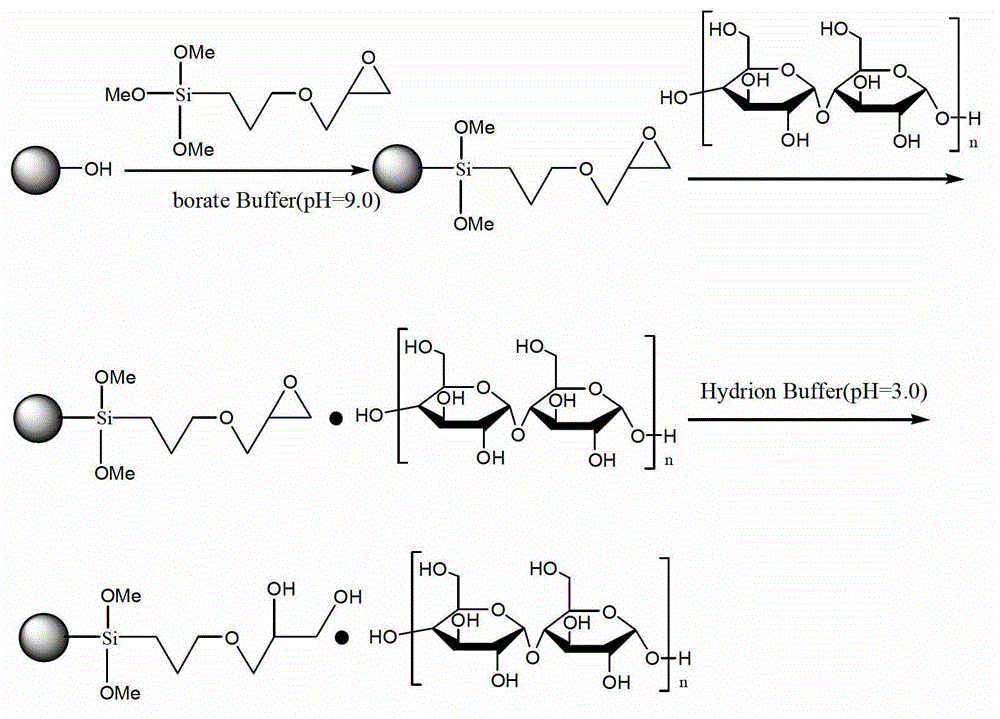

[0037] The present invention provides a preparation method of hydrophilic silica gel chromatography packing for separating water-soluble polymers and proteins, which comprises the following steps:

[0038] A. Activation of silica gel to obtain activated silica gel;

[0039] B. Perform epoxy modification on the activated silica gel to obtain epoxy modified silica gel;

[0040] C introduce a hydrophilic polymer into the epoxy modified silica gel to prepare a hydrophilic polymer modified silica gel; and

[0041] D Hydrolyze the hydrophilic polymer-modified silica gel to prepare the hydrophilic silica gel chromatographic packing for separating water-soluble polymers and proteins.

[0042] Step A includes: washing the silica gel with distilled water, then soaking it with an aqueous solution of hydrofluoric acid, then washing with distilled water to neutrality, and finally washing with acetone and drying.

[0043] Wherein, step B includes: using boric acid buffer as a solvent, the activated si...

Embodiment 1

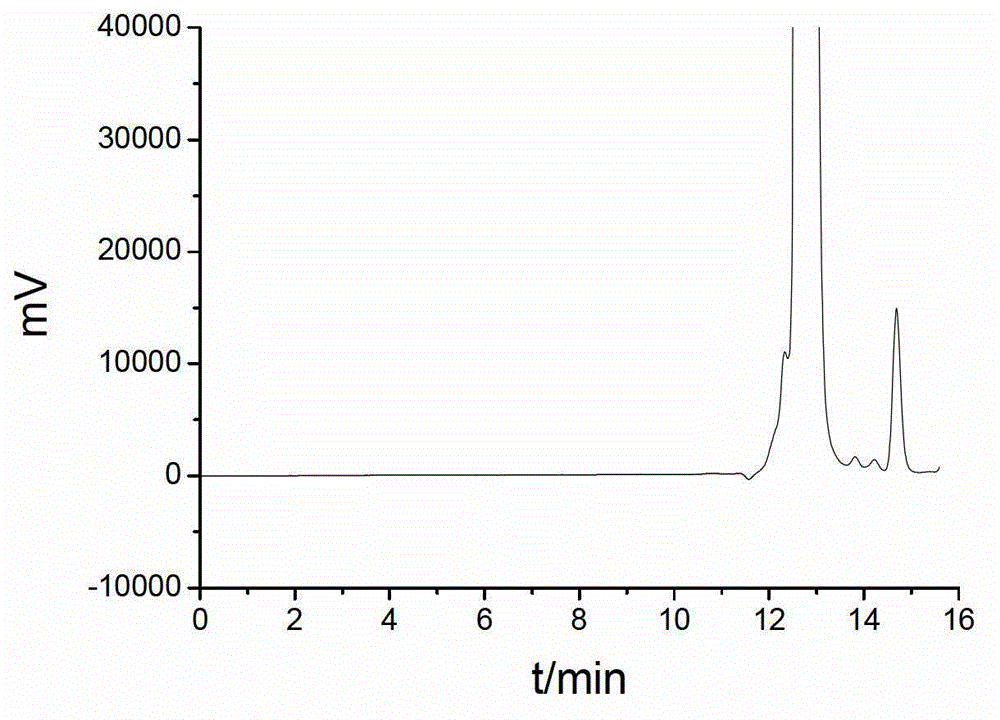

[0048] Example 1: Preparation of hydrophilic silica gel chromatography packing for separating water-soluble polymers and proteins

[0049] (1) Add 50 g of silica gel to a 500 mL reaction vessel, add 200 mL of distilled water, stir for 30 minutes, filter, and repeat this step twice. Then add 400 mL of 0.08% hydrofluoric acid aqueous solution with a mass ratio of 0.08%, stir for 24 hours and wash with distilled water to neutrality, and finally add 200 mL of acetone to wash, filter, and dry at 110°C for 12 hours to obtain activated silica gel;

[0050] (2) Add 400mL pH=9.0 boric acid buffer solution to 500mL reaction vessel (equipped with condenser, mechanical stirrer and thermometer) ( Buffer, purchased from Guangzhou Huayuehang Instrument Co., Ltd.), 50g activated silica gel and 100mL γ-(2,3-glycidoxy)propyltrimethoxysilane, stirred at 80°C for 30 minutes; obtained epoxy Group modified silica gel;

[0051] (3) Add 100g of soluble starch to the reaction vessel, reflux and stir at 97°...

Embodiment 2

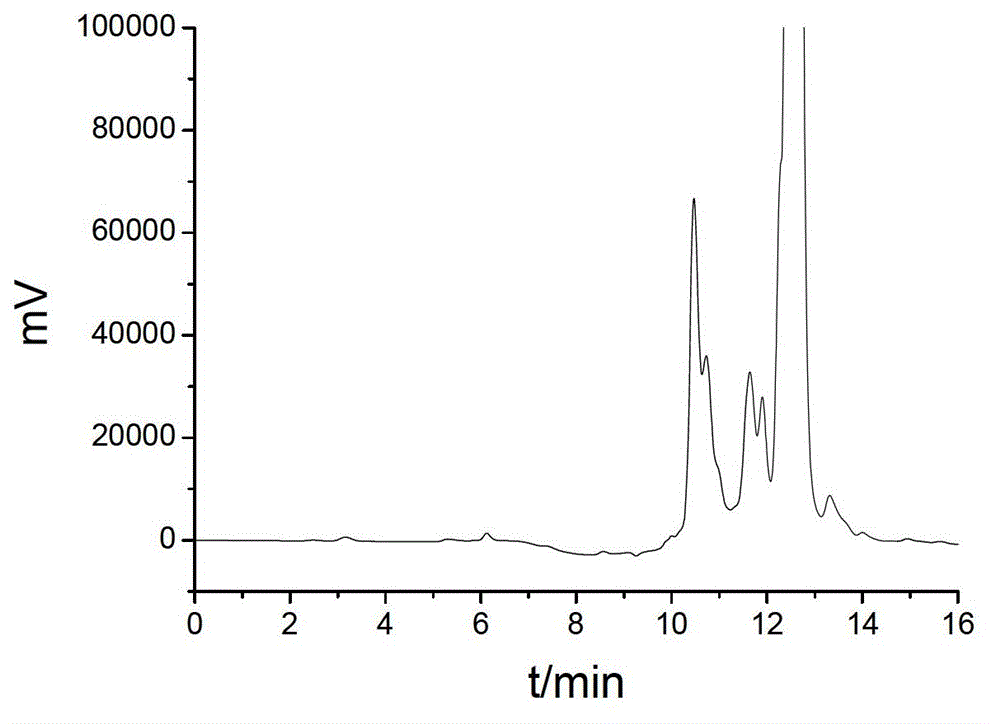

[0053] Example 2: Preparation of hydrophilic silica gel chromatography packing for separating water-soluble polymers and proteins

[0054] (1) Add 50 g of silica gel to a 500 mL reaction vessel, add 200 mL of distilled water, stir for 30 minutes, filter, and repeat this step twice. Then add 400 mL of 0.08% hydrofluoric acid aqueous solution with a mass ratio of 0.08%, stir for 24 hours and wash with distilled water to neutrality, and finally add 200 mL of acetone to wash, filter, and dry at 110°C for 12 hours to obtain activated silica gel;

[0055] (2) Add 450mL pH=9.0 boric acid buffer solution, 50g activated silica gel and 150mL γ-(2,3-epoxypropoxy)propyl to the 500mL reaction vessel (equipped with condenser, mechanical stirrer, and thermometer) Trimethoxysilane, stirred and reacted at 80°C for 30 minutes; obtained epoxy group modified silica gel;

[0056] (3) Add 150g of dextran to the reaction vessel, reflux and stir at 97°C for 20-22 hours; after the reaction, cool and reflux ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com